THE OTHER MAN'S GRASS

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Gilbert Richardson has delivered turf to some of our most hallowed sporting arenas, including Wimbledon. It is a difficult and tempremental load to shift, but it has its rewards.

• Gilbert Richardson knows where the grass grows greener: right beneath his feet. As one of the country's biggest specialist turf hauliers, he readily admits that the going is normally good.

"We get high rates in this business, but we really have to perform," he says. Time, weight, weather and distance are even more critical than usual when you are driving several tonnes of high quality grass from Yorkshire to the All England lawn tennis courts at Wimbledon, for instance. Gilbert Richardson Transport's main problem is that the company is shifting a high-cost living product all over the UK, and that product comes closer to death every minute it is on the truck.

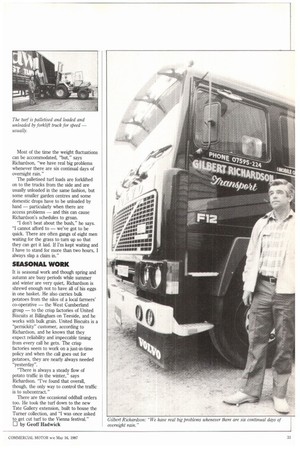

"The grass can never be more than 24 hours old when it is reiaid," says Richardson, and every delivery he makes is a juggling act with a bewildering array of variables. Overnight frost can halt everything; there are three different grades of grass to sort out, and rain can increase the weight of turf by a staggering 25%. The grass is grown in a series of flat fields in an eight-kilometre radius of Richardson's depot and farm at Barnaby Moor on the A1079 between York and Hull. Once it has been sliced up into 20kg 'butter-pat' rolls and stacked into pallets, the race is OD.

The grass heats up inside the roll and will turn yellow if left for too long. "There are no Monday deliveries, because the turf is cut on Mondays, and very few Friday deliveries because it cannot be left standing anywhere.

Richardson hauls under contract for Rolawn Turf, Europe's leading grass growers. The firm has more than four million square metres of grass growing at any one time in Britain, at four different production units — the Humberside operation is Rolawn's biggest and the company sells two million rolls of turf every year. Richardson hauls the turf from Humberside to Rolawn's other UK bases near Edinburgh, Bedford and Guildford as well as direct to customers throughout the country. He has been working with transport since he left school at 16 to join his father's company, a carrot and potato merchants. He drove his father's truck and when he took over steered the family business away from farming and into haulage. The small amount of land the family farm owns has been rented out; Richardson thinks farming is hard work for little return. He used to run his own tractor units but today he contracts out to a string of local owner-drivers and runs only one machine — a Volvo F12 Intercooler with a lift-up rear axle. It has been beautifully liveried by one of his former employees who left to set up his own bodyshop and painting business, called Pocklington Coachworks.

TURF PALLETS

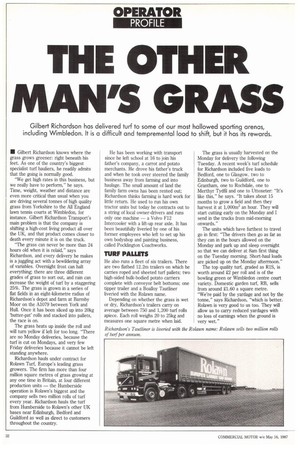

He also runs a fleet of six trailers. There are two flatbed 12.2m trailers on which he carries roped and sheeted turf pallets; two high-sided bulk-bodied potato carriers complete with conveyor belt bottoms; one tipper trailer and a Boalloy Tautliner liveried with the Rolawn name.

Depending on whether the grass is wet or dry, Richardson's trailers carry on average between 750 and 1,200 turf rolls apiece. Each roll weighs 20 to 25kg and measures one square metre when laid.

The grass is usually harvested on the Monday for delivery the following Tuesday. A recent week's turf schedule for Richardson included five loads to Bedford, one to Glasgow, two to Edinburgh, two to Guildford, one to Grantham, one to Rochdale, one to Merthyr Tydfil and one to Uttoxeter: "It's like this," he says. "It takes about 15 months to grow a field and then they harvest it at 1,000m2 an hour. They will start cutting early on the Monday and I send in the trucks from mid-morning onwards."

The units which have furthest to travel go in first: "The drivers then go as far as they can in the hours allowed on the Monday and park up and sleep overnight so that we can deliver at 8arn first thing on the Tuesday morning. Short-haul loads are picked up on the Monday aftermoon."

The top quality turf, graded as R1S, is worth around £2 per roll and is of the bowling green or Wimbledon centre court variety. Domestic garden turf, RB, sells from around £1.60 a square metre. "We're paid by the yardage and not by the tonne," says Richardson, "which is better. Rolawn is very good to us too. They will allow us to carry reduced yardages with no loss of earnings when the ground is very wet." Most of the time the weight fluctuations can be accommodated, "but," says Richardson, "we have real big problems whenever there are six continual days of overnight rain."

The palletised turf loads are forklifted on to the trucks from the side and are usually unloaded in the same fashion, but some smaller garden centres and some domestic drops have to be unloaded by hand — particularly when there are access problems — and this can cause Richardson's schedules to groan.

"I don't beat about the bush," he says. "I cannot afford to — we've got to be quick. There are often gangs of eight men waiting for the grass to turn up so that they can get it laid. If I'm kept waiting and I have to stand for more than two hours, I always slap a claim in."

SEASONAL WORK

It is seasonal work and though spring and autumn are busy periods while summer and winter are very quiet, Richardson is shrewd enough not to have all of his eggs in one basket. He also carries bulk potatoes from the silos of a local farmers' co-operative — the West Cumberland group — to the crisp factories of United Biscuits at BiHingham on Teeside, and he works with bulk grain. United Biscuits is a "pernickity" customer, according to Richardson, and he knows that they expect reliability and impeccable timing from every call he gets. The crisp factories seem to work on a just-in-time policy and when the call goes out for potatoes, they are nearly always needed "yesterday".

"There is always a steady flow of potato traffic in the winter," says Richardson. "I've found that overall, though, the only way to control the traffic is to subcontract."

There are the occasional oddball orders too. He took the turf down to the new Tate Gallery extension, built to house the Turner collection, and "I was once asked to get cut turf to the Vienna festival." 0 by Geoff Hadwick