HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid 'for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosrire of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to " The Editor, The Commercial Motor, 7-15, Resebery Avenue, London, E.C.1."

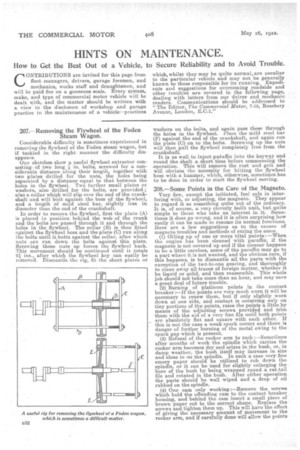

207.—Rerrioving the Flywheel of the Foden Steam Wagon.

Considerable difficulty is sometimes experienced in removing the flywheel of the Foden steam wagon, but if tackled in the right manner the difficulty disappears.

Our sketches show a useful flywheel extractor consisting, of two long in. bolts, screwed for a considerable distance along their length, together with two plates drilled for the nuts, the holes being separated by a distance equal to that between the holes in the flywheel. Two further small plates or washers, also drilled for the bolts, are provided ; also a collar which will slip over the end of the crankshaft and will butt against the boss of the flywheel, and a length of mild steel bar, slightly less in diameter than the end of the crankshaft.

In order to remove the flywheel, first the plate (A) is placed in position behind the web of the crank and the bolts are passed through it and through the holes in the flywheel. The collar (B) is then fitted against the flywheel boss and the plate (C) run along the bolts until it butts against the collar, after which nuts are run down the bolts against this plate. Screwing these nuts up forces the flywheel back. This movement should be continued until it totals 21 ins., after which the flywheel key can easily be removed. Dismantle the rig, fit the short plates or

washers on the bolts, and again pass these through the holes in the flywheel. Place the mild steel bar (F) against the end of the crankshaft, and again run the plate (0) on to the bolts. Screwing up the nuts will then pull the flywheel completely free from the crankshaft.

It is as well to inject paraffin into the keyway and round the shaft a short time before commencing the .operation. This will remove the rust and grit and will obviate the necessity for hitting the flywheel boss with a hammer, which, otherwise, sometimes has to be done in order to start the flywheel moving.

208.—Some Points in the Care of the Magneto.

Very few, except the initiated, feel safe in interfering with, or adjusting, the magneto. They appear to regard it as something quite out of the ordinary. It is of course, a very cleverly built unit, but quite simple to those who take an interest in. it. Sometimes it does go wrong, and it is often surprising how easily it can be made to resume its normal functions. Here are a few suggestions as to the causes of magneto troubles and methods of curing the same. (1) Oiling up of one or more vital points: —When the engine has been cleaned with paraffin, if the magneto is not covered up and if the cleaner happens to be a little careless, some of the paraffin may go to a part where it is not wanted, and the obvious cure, if this happens, is to dismantle all the parts with the exception of the two-to-one gearing, and thoroughly to clean away all traces of foreign matter, whether it be liquid or solid, and then reassemble. This whole job should not take more than an hour, and may save a great deal of future trouble. (2) Burning of platinum points in the contact

breaker the points are very much worn it will be necessary to renew them, but if only slightly worn down at one side, and contact is occurring only on tiny portions of the points, raise the points a littleby means of the adjusting screws provided and trim them with the aid of a very fine file until both points are absolutely flat and square with each other. If this is not the case a weak spark occurs and there is danger of further burning of the metal owing to the spark gap which is present.

(3) Refusal of the rocker arm to rock :—Sometimes after months of work the spindle which carries the rocker arm becomes dry and seizes in the bush, or, in damp weather, the bush itself may increase in size and close in on the spindle. In such a case very fine emery paper should be utilized to rub down the spindle, or it can be used for slightly enlarging the bore of the bush by being wrapped round a rat-tail file and rotated in the bush. After either operation the parts should be well wiped and a drop of oil rubbed on the spindle.

(4) One cam only working :—Remove the screws which hold the offending cam to the contact breaker housing, and behind the cam insert a small piece of brown paper cut to the correct shape. Replace the screws and tighten them up. This will have the effect of giving the necessary amount of movement to the rocker arm, and if carefully done will allow the points

to open the correct amount, which is between 1-50th nd 1-64th of an inch.

(5)Seizure of the spring on the distributor brush :— If the spring has seized, remove it ; straighten it jilt is bent slightly, and replace spring and carbon brush. A new spring costs only a very small amount if a replacement has to be made.

(6) Shorting of the current in the armature :—This is usually a job for the expert repairer, but it is • THE COMMERCIAL MOTOR occasionally caused by a loose strand of wire which it may be possible to remove. (7) Breakdown in the condenser :—This is practically always a job for the magneto repairer, and should not be tackled by the amateur. The condenser is a most important part of the magneto as its duty is to act as a buffer for the primary current, helping to produce a greater pressure in the secondary, winding and

i reducing sparking n the contact breaker.