DENIZENS

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

OF THE DIRT

Today's all-terrain trucks are designed to perform daunting tasks in daunting conditions. We test 10 denizens of the dirt to see if their performances match their impressive looks.

/ The Grand Old Duke of York, it appears, had little trouble in persuading his men up and down the hill. He even managed to get them halfway up the hill again to further the cause of scanning rhymes. But what if he wanted to get a cannon up the hill, or 20 tonnes of rubble? Seventeenth century military industrial relations tended to be of a strictly one-sided nature, but it is a fair bet that even the Old Duke's ever-willing counter-marching troops might have blanched at the thought of toiling up the hill with such a load.

To prevent the embarrassment of our military and political leaders, and to further speed the wheels of industry, the slave or press-ganged conscript has now been replaced by the lorry, which in turn have progressed to a heady state of sophistication. Lugging cannons up hill is a matter of consummate ease for most of these vehicles, so we felt it was time we took a close look at some of them, and put them through their paces.

Ten vehicles were duly assembled at our gruelling Surrey off-road test track over the course of two days, with the mornings spent on objective performance tests and the afternoons spent driving them off-road for a subjective evaluation. Comparisons have been kept to a minimum, as each is particularly suited to specific tasks, with parameters like fuel consumption, acceleration or payloads compromised in the interests of getting the job done safely, quickly and efficiently.

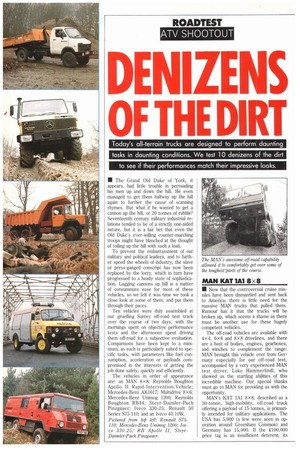

The vehicles in order of appearance are: an MAN 8x8; Reynolds Boughton Apollo II Rapid-Intervention-Vehicle; Mercedes-Benz AK1617; Multidrive 8x6; Mercedes-Benz Unimog 1200; Reynolds Boughton RB44; Steyr-Daimler-Puch Pinzgauer; lveco 330-25; Renault 50 Series S75-110; and an Iveco 40.10W. Pictured from top left: Renault S75110, Mercedes-Benz Unimog 1200; Theco 330.25; RB Apollo II, SteyrDaimler-Puch Pinzgauer.

MAN KAT 1AI 8 x 8

• Now that the controversial cruise missiles have been dismantled and sent back to America, there is little need for the massive MAN trucks that pulled them. Rumour has it that the trucks will be broken up, which seems a shame as there must be another use for these hugely competent vehicles.

The off-road vehicles are available with 4x4, 6x6 and 8x 8 drivelines, and there are a host of bodies, engines, gearboxes, and winches to complement the range. MAN brought this vehicle over from Germany especially for our off-road test, accompanied by a very experienced MAN test driver, Luke Hammerlindl, who showed us the startling abilities of this incredible machine. Our special thanks must go to MAN for providing us with the opportunity.

MAN's KAT 1A1 8x8, described as a 30-tonne, high-mobility, off-road truck offering a payload of 15 tonnes, is primarily intended for military applications. The USA has 5,000 (a few were seen in operation around Greenhorn Common) and Germany has 15,000. If the 2100,000 price tag is an insufficient deterent, its 2.9m overall width precludes legal civilian on-road use in the UK.

A military version of MAN's 12-litre 132866 six-cylinder, in-line charge-cooled engine, rated at 265kW (360hp), drives through a transmatic fluid clutch to a ZF 16-speed synchromesh gearbox and on to a transfer box with inter-axle lock. Both front steering and rear axles, with planetary final drives in the wheel hubs to maximise ground clearance, are available with differential locks.

The suspension makes use of progressively acting coil springs, with shock absorbers on all axles. Full-air service brakes are complemented by a park brake incorporating spring brake actuators on both of the rear axles. The mainly steel cab has a flat front windscreen and has a removeable GRP roof to reduce overall height for transport by plane, Contoured driver and passenger seats offer limited restraint to the occupants. In addition to the usual instrumentation the binnacle includes a gauge to monitor torque converter temperature.

Difflocks are operated by switch control and the pendant clutch and brake pedals are mounted at about 155rrun above the rubber floor covering.

On road the ride is good (unladen, at least) but the cab became quite noisy as speed increased. The torque converter enables a high gear to be used when starting off, and on the move it automatically increases drive torque at low speeds. Gearchanging, found to be smooth and fast, is accomplished in the normal way.

Off-road it proved to be a go-anywhere vehicle able to cross rough ground at speed, plug through deep mud and tackle the steepest loosely-surfaced inclines. The large (500mm) steering wheel and power steering coped with the heaviest conditions without subjecting the driver to excessive feedback. • Reynolds Boughton's self-proclaimed Apollo "pocket rocket" rapid-intervention vehicle is built by the company's Devon operation. It sells mainly to aerodromes, but also to the police and fire services.

The Apollo uses Boughton's four-wheeldrive system with a General Motors torque converter and three-speed automatic gearbox. The Boughton transfer box gives a wide variety of power take-off facilities, and disc brakes are fitted to the front axle to stop the raging five tonnes of petrolpowered beasty when in full cry.

On the road the big Rolls Royce veeeight makes its presence felt under most throttle openings. But the overall in-cab noise is quite low, and the power delivery is smooth.

With neutral steering, and a simple-touse transmission, the Apollo makes driving a relaxed process on tarmac.

With its bright yellow paintwork, huge steel bumpers, and the "Rolls Royce Motor Cars" badge worn proudly on its bonnet, the Apollo II looks like the kind of machine which arrogantly sweeps past Range Rovers and the like in the fast lane of a motorway.

Once in the driver's seat the impression of size and solidity is reinforced, with a large steering wheel, straightforward controls and instrumentation, and plenty of bare metal in the cabin. Levers for the automatic transmission, the park brake, and the cliff-locks are mounted on the substantial transmission tunnel between driver and passenger.

Allowing for the fact that the Apollo was fully laden (at 5.18 tonnes), on-road performance was brisk, with a deepthroated vee-eight burble accompanying full-throttle acceleration. Feel at the controls, however, is slightly crude, with a somewhat sluggish kickdown from the three-speed transmission and a "wooden" brake pedal. Noise levels are quite high, with the engine being especially prominent, while the ride was rather unsettled. Cornering generates a moderate amount of body roll.

On a muddy and rutted off-road surface, the overriding impression is of a choppy and poorly-controlled ride. Ths is not only uncomfortable, but makes it very difficult to steady the foot on the throttle or the brake, with the result that progress is invariably jerky. On our vehicle, a sustained period off-road also proved sufficient to dislodge one of the engine's coolant pipes.

Traction on tyres designed for onand off-road use prove more than adequate in muddy going, while the combination of a powerful engine and an automatic gearbox make life easy for the driver.

As an all-weather, all-surface, emergency vehicle with a surprising turn of speed, the Apollo should easily suit the requirements of users such as airports. For those demanding off-road performance in severe conditions, the crude suspension design dictates that the Apollo might not be the most appropriate choice.

MERCEDES-BENZ AK1617

• The Mercedes-Benz AK1617 was introduced into the UK early last year to strengthen the company's position in the public utility and municipal market. To date it is M-B's least successful model, but if expectations of 40 to 50 registrations are realised this year it will become a viable proposition.

Built with the standard medium Woerth cab, the new 16.8-tonne chassis shares the 0M366A engine and G4 six-speed synchromesh gearbox of the 1617 Mercedes-Benz 17-tonner. The company's own two-speed transfer box is mounted between the wheelbase providing permanent drive to both front and rear axles. Cross-axle difflocks are an option supplemented by an inter-axle differential and can be selected independently.

Inside, the cab is very quiet and, despite a long throw of the gear lever, gearchanging is smooth and easy. German legislation demands that steering control be retained if the power steering assistance fails, so a large (550mm) diameter steering wheel is fitted. This, and the position of the gearstick, prevents any possibility of easy cross-cab access.

Pendant clutch and brake pedals are located at a sensible 135rnm above the rubber floor covering.

An Isri 85000 mechanical suspension seat has all of the usual adjustments, plus a tilt facility for the squab. Where a second passenger seat is omitted a central tray can be fitted to complement the document pouch included on the rear panel and pair of pockets in the truck's header rail.

The park brake lever, installed to the right of the steering wheel on the end of the fascia, is within easy reach.

Instrumentation includes both tacho and rev counter as well as oil, air, tempera ture and fuel. Without a load, and driven on metalled roads, the steering remained surprisingly neutral.

The first thing to remember about this vehicle when driving off-road is that momentum alone will not get a laden Mercedes 17-tonner up hills. Grandiose plans to change down the box quickly will result in a baulking synchromesh gearbox, and an embarrassed driver as the speed drops too sharply to select a gear.

No doubt some drivers with years of experience with the vehicle can show their prowess by doing the unthinkable for mere mortals. For the rest of us, however, a slow approach to the hazard, the selection of the correct gear (first in most cases), and a slow controlled climb with the rev counter hovering just above the red sector will safely suffice.

The vehicle has plenty of grip and picks its own path, directed solely by the steering wheel. The ride quality, even when laden, is a little bouncy, but the long wheelbase ensures there is little forward pitching. Nevertheless it is difficult to keep a foot steady on the pedals.

The steering is light and positive with plenty of feel. The exhaust-brake works well when the revs are high enough, but we found the brakes a little sharp for a laden vehicle and it is difficult to maintain steady braking on a long steep slope. The restart capability was all we would have expected of what is, after all, a road gritter in application.

MULTIDRIVE 8x6

• Designed for overseas markets, the AWD MTM 55 uses the Multidrive system, where the axles of the trailer are both steered and driven. This means that the vehicle is effectively an 8 x 6 configuration, with incredible manoeuvrability due to the steered rear wheels. AWD claims that at full turn the track of the rear wheels increases by 20%, .which increases the stability when tipping.

All the components of the truck come from different manufacturers, with the exception of the chassis, trailer and cab. The engine is from CaterpillAr, the gearbox from Fuller (a nine-speed rangechange unit), GIS.N and ZF-MPM provide the front and rear axles respectively, the brakes are from Rockwell, and the rear suspension is from Tadchurch. Finally, the tipping gear is from Edbro.

In spite of the various origins of the AWD, the standard of manufacture seems quite good. The cab emitted no squeaks, even when pushed hard, and the rest of the truck has a good integral feel about it.

With its gross weight of 53 tonnes, the AWD has a payload of 35 tonnes, so civil engineering sites, and opencast mines could be looking at this vehicle instead of the Volvo BM-type vehicles. A small fleet of them is under evaluation in the Sudan and one has recently been shipped to Thailand for an assessment by its armed forces. Several companies in Europe have also expressed interest in the system. AWD also claims that the vehicle can be driven on the road (with special approval in the UK), as the width is only 2.5m Reversing the Multidrive articulated vehicle takes a lot of practice. First, it has to be broken (like an artic) then it must be steered like a rigid and a lot of patience is needed to position it precisely.

To protect the trailer steering, operated by levers passing through the chassis, articulation is restricted to 300 by stops attached to the fifth wheel.

Unladen on wet downhills, the wheels are easily overbraked and steering is light, but with limited articulation there is little chance of a full blooded jack-knife.

The Cat engine's massive torque is well controlled by the Fuller box which, though extremely unforgiving, engages positively enough.

Regrettably, the vehicle was unladen when we drove it and bounced considerably, particularly the cab. It handled the woodland tracks with ease and skipped up the steep twisting 33.3% (1-in-3) tracks in third gear without hesitation, with difflocks engaged.

It left the lasting impression that, even with a full load aboard, positive traction would have been guaranteed. It drives down these gradients and feels very stable in doing so, thanks to the Multidrive rear steering and fifth-wheel stop arrangement.

M-B UNIMOG 1200

• According to the glossy brochures, the Mercedes-Benz Unimog is a specialist vehicle which can pull, lift, carry, plough and dig in some of the world's most inaccessible places. The range divides into four basic weight/power categories, of which only the 1000-1650 model range is available here.

Power is provided by the new 0M366 range of diesel engines, and a range of gearboxes can provide up to 24 gears. The suspension is live-axles with portal axles, coil springs, telescopic dampers, and disc brakes all round.

After that the potential buyer is alone, as the choice of extras can be bewildering. A whole range of power-take-offs can be ordered; hydraulic power can be specified at the front and rear, and the tools options are endless.

In practice the Unimog is used in the main by farmers, who can tax it as an agricultural vehicle; forestry companies, who use the vehicle as a specialised winch and transport; and the military, who use it as a go-anywhere weapons carrier.

It is an exuberant creature which pitches, bounces, crashes and jolts along, even when laden. This is partly due to the short wheelbase which helps make the Unimog superbly manoeuvrable and agile over rough ground. Our test vehicle suffered large amounts of roll, mainly due to the low-flotation of the balloon tyres.

There is enough power to propel the laden Unimog at speeds approaching the legal limits. With its massive gearing advantage it will pull 500 tonnes — the lowest available gear, with the optional super-crawler range, will propel the little truck at a dizzying speed of 80metres/hr1

Badly-adjusted brakes stopped the vehicle from holding on a 33% (1-in-3) slope, but it easily restarted on the same slope. The steering is a little too light for much on-road use, but reaching the vehicle's top speed of 80krn/h should be no problem.

It is shame that all the Unimog's instruments and the steering column stalks are parts no longer used by the rest of the Mercedes commercial vehicle range, and it is the last vehicle to get the updates (witness its newly acquired 0M336 engine, which has been in the rest of the truck range for some time).

For all that, the Unimog is a very useful tool, and tremendously versatile. But the reins to that versatility — the host of levers, and switches on the cab floor — ensure that the Unimog will never be an easy vehicle to master completely.

RB44

• We have already tested the Reynolds Boughton RB44 (CM 19-25 May 1988), so it was a familiar vehicle that rolled onto the test track. The first example made its public debut at the British Army Equipment Exhibition in 1986, galloping across an imaginary battlefield in Aldershot, dragging a 105rnm howitzer.

Derived from the Renault 50 Series cab shape, the RB44 retains a number of features from the original civilian version. Reynolds Boughton has won a £26 million contract to supply the Ministry of Defence with 1,000 vehicles, which should ensure that the 5.3-tonne 4x4 is a familiar sight in the armed forces of other countries.

Its Perkins 110T DI blown diesel displaces four litres and delivers 80kW (109hp). The gearbox is a departure from normal MoD practice, being a Chrysler Torqueflite A727 three-speed automatic. Reynolds Boughton differentials complete the driveline, and the steering system is a ZF power-assisted unit.

Reynolds Boughton's so called twotonne military model offers a payload of about 2.5 tonnes within the 3,530kg GVW, and a towing capacity of 7.5 tonnes. It is to be built on the line at Dunstable, incorporating RB's two-speed, morse chain, transfer box providing permanent four-wheel-drive, and RB suspension.

Changing from high to low ratio, or reverse, is done with the vehicle stationary to remove the loading from the gears, but is still a bit noisy with some grating.

The cab provides little in the way of stowage space, but instrumentation, including a vacuum gauge for the braking system, is good. Plastic seats and rubber floor covering are utilitarian. The brake pedal is quite high at around 155tnm.

When we tested the vehicle off-road, there was a noticeable amount of understeer, which RB claims to have solved with heavier rear suspension. The modification appears to have worked, and the steering wheel angles gave a fair indication of where the little truck would be half way through the corner.

The Torqueflite unit comes as a surprise, particularly on the Alpine route of the test. Nearing the summit the vehicle slowed dramatically, then seemed to almost stall, before changing into first and charging away again. Hills should really be taken at a run with the RB44, allowing the gearbox to do the work.

The other feature of the driveline is that it allows the vehicle to leap up and down when restarting on unsurfaced hills. At its worst, this means that the vehicle stays in the same place, leaping up and down, with the gearbox in top gear and maximum revs on the clock. The selection of cliff-locks, and a more gentle application to the throttle gave a slow, but sure progress up the hill again.

It seems that driving the RB44 is a matter of technique as much as anything, there are times to floor the throttle to get the best from the little beast, and others when discretion is the better part of valour. Let's hope the army drivers appreciate this.

S-D-P PINZGAUER

• Derived from the Steyr-Daimler-Puch Haflinger, and launched in 1971 (six years after its announcement), the Pinzgauer is a sophisticated little all-terrain vehicle, with a fairly horrendous price tag of £45,000 (ex-VAT). Mind you, you do get an awesome level of off-road capability for your money that should appeal to the emergency services and the military.

The Pinzgauer is built in Austria and marketed in the UK by a division of James Jones and Son of Larbert, Stirlingshire, in 4 x4 and 6x 6, manual and automatic versions. We tested the automatic 6x6 turbo-diesel.

Power is courtesy of the Volkswagen LT derivative fitted into Volvo passenger cars. The six-cylinder, charge-cooled 2.4litre IDI diesel delivers 77kW (103hp) of power via a ZF four-speed gearbox, an open, off-set propellor shaft and a twospeed transfer box into the central backbone chassis, which also contains the three twin-crown wheel and pinion differentials. The half-shafts are totally enclosed, and at their ends are portal axles, which increase the ground clearance without letting the suspension drag in the dirt.

Normal drive is to the rear bogie, which is suspended like a tipper on two leaf springs. Drive to the coil-sprung front axle can be engaged on the move, pneumatically or automatically, when low range is selected. All the aides have differential locks, which can be engaged on the move as well

With its slightly toytown-like appearance, the Pinzgauer is a classic example of

form following function. Inside the cab, the controls continue the no-frills approach, and the driver has a basic but comfortable and efficient environment.

On the track, the Pinzgauer is very similar to a saloon car. The engine and four-speed automatic gearbox provides smooth and responsive performance; noise levels are respectably low, and the supple suspension gives a stable ride. More remarkably, these comments are equally applicable off road.

With six-wheel drive and independent suspension for all wheels, the Pinzgauer maintains progress over even the most exteme terrain. The four-speed gearbox offers a hold facility on first, second and third to allow engine braking while the torque converter gives 100% lock-up in top gear. Cross-axle difflocks can be brought into operation at any speed.

The small size of the Pinzgauer aids its manoeuvrability, and neutral handling helps the driver keep control in difficult circumstances. It also says much for the capability of the vehicle that drivers with no experience off-road felt immediately at ease. Overall, an expensive but extremely capable off-road tool.

IVECO 330.25

• lveco's 6x6 prototype, imported for evaluation by the military, has an off-road capacity of 33 tonnes. Its sparse cab owes a great deal to its Third World markets but we are assured that a European specification would give a higher standard.

The driveline incorporates a ZF synchromatic torque converter, mounted at the rear of the engine with the eightspeed ZF Synchroma tic gearbox located further to the rear. The two-speed transfer box divides the drive between the 7.5tonne front axle with planetary reduction gears on the wheel hubs and twin rear axles rated at 26 tonnes (also with planetary gears). Cross-axle and inter-axle pneumatically operated lockable differentials maximise traction.

Large (12.00R20) tyres gave positive signs of understeer while the feedback through the power steering made the large (500mm) steering wheel seem heavy. The WSK converter and clutch, developed with Ficthel and Sachs, locked up automatically at quite low revs and, without a load, avoided the need to change down.

Its engine was very slow to warm up and on occasions would cut out. This was probably due to low oil levels in the torque convertor. However, once under way the engine revved quite smoothly. The ZF Synchromatic box changed gear easily enough, but the shift lever tended to jump across the gate too freely for comfort.

Over rough ground, the unladen Iveco bounced around with the cab rocking too on its rubber bushidamper mountings. With individual and inter-axle diff-locks engaged, however, the truck felt very capable of transporting its 33 tonnes.

RENAULT S75-110

• The Renault S75 is a civilian alternative to the Boughton system. With single wheels and tyres it has a payload of 3,236kg. Our test vehicle, delivered with a test load, incorporated Ampliroll demount bodywork.

This 4x4 is a factory conversion based on the standard two-wheel-drive 50 Series model. The 3.88-litre turbocharged Perkins Phaser diesel engine, giving 30kW (110hp), is retained along with the manual five-speed Turner gearbox and Renault's spiral bevel rear axle, to which a Reynolds Boughton two-speed transfer box and Renault front-drive axle are added.

Within the all-steel, semi-forward control cab, all of the controls for the gears, transfer box, difflock and park brake are between the seats. Foot pedals are located quite high above a sloping floor. The air/hydraulic brakes seemed heavier than the vacuum-assisted system on the Reynolds Boughton model.

The two-spoke, 450mm diameter, steering wheel and power assistance made light work of the steering. Instrumentation includes an automatic tachograph with the usual fuel, temperature and air pressure gauges, while an auto-stop is incorporated with the starter switch/column lock.

Noise rises in line with speed and at 80km/h the level is quite high. Off-road, the steepest of the hills slowed the vehicle to the point where we had to use first gear, but the engine continued to pull strongly. The service brakes, however, were found wanting, failing to hold and prevent the vehicle rolling some 20m back down the slope before arresting it.

IVECO 40.10WM

• Iveco's 40.10WM, a military mediummobility vehicle, has been on trial with the British Army. It is a non-dedicated 4x4 version of a civilian model being introduced in Italy and shares many components with the Turbo Daily, such as the engine, gearbox, rear axle and brakes. There is a two-speed Borg Warner transfer box mounted at the rear of the main, five-speed all-synchro gearbox.

The change from two to four-wheeldrive has to be made while the vehicle is stationary. A single lever, between the seats, is used to select 4X4 high ratio, 4x2 high ratio, neutral or 4x4 low ratio drive, but problems in the linkage of the test vehicle prevented full engagement of the high ratio four-wheel drive, so we were unable to travel far in this mode before the box jumped out of gear.

The park brake lever is to the right of the driver's seat, while pendant service brake and clutch pedals are mounted quite high above the floor. A good sized steering wheel made light of steering effort in two-wheel-drive, but naturally becomes heavier when four-wheel-drive is used.

Basic instrumentation includes a speedo with water temperature and fuel gauges, while warning lamps indicate operation of four-wheel-drive, difflock, park brake, direction indicators and lights, as well as low oil pressure and battery charge.

A canvas hood, with zip-up plastic side windows, provides protection against the elements. The flat front screen can fold down on to the short bonnet. Pockets on each of the doors are the only provision for stowage. With a four-tonne GVW, the Iveco 40.10WM offers a 1.5-tonne payload and will tow a 1.5-tonne trailer.