THE EQUALISERS

Page 116

Page 117

If you've noticed an error in this article please click here to report it so we can fix it.

Why do operators seem to have overlooked manufacturers' claimed potential savings on fitting equalisation systems to their vehicles? We take a look at today's developments to find out why.

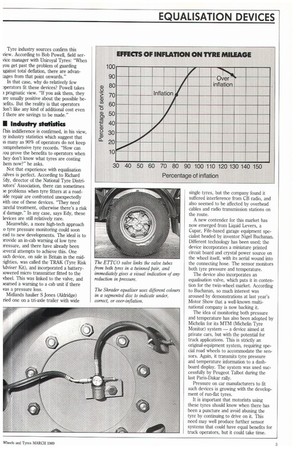

• Operators running vehicles or trailers with twinned tyres can boost tyre mileage by 25% and improve fuel consumption, simply by using some form of equalisation device to balance the pressure between adjacent tyres. Moreover, modern electronics make it possible to build in-cab low-pressure warnings into the system. Eventually no vehicle will be without one. That is what the manufacturers would have us believe, anyway. But what is the basis for their claims, and are they borne out in practice?

The essential problem which these systems address is that inner tyres can be prone to neglect. Too many drivers (and even their employers) adopt an out-ofsight out-of-mind attitude to them. A slow puncture on an inner tyre can pass unnoticed until irreparable damage has been done to its casing. Meanwhile, the outer tyre suffers an overload and wears unevenly and too fast. Even a full-scale blow-out of an inner tyre is sometimes not obvious at first, especially on an unladen multi-axle vehicle.

Equalisation valves work by linking the valve stems of adjacent tyres ensuring (in theory at least) that there is no undue wear through unequal pressures. At the same time, the system gives a clear visual indication if the pressure in the two tyres falls below a given level, so it also serves as a warning device.

Two systems share most of this market in the UK — the American Shrader Visualiser, and the Swiss ETTCO deflation monitor. Shrader has a UK company at Tamworth, while the ETTCO system is sold by F and S Equipment of Oldbury, West Midlands. The systems differ in detail, but work along similar lines. Even their prices are very much on a par — around £80 per axle set, with discounts for large fleet orders.

However, neither system has yet done more than scratch the surface of the potential market. Operators have been slow to respond, and the weight-savings of wide single tyres have removed the need on some tri-axle trailers. So what is the experience of existing users?

• Careful monitoring

What soon becomes clear is that the best results need commitment, as well as careful monitoring, to quantify the findings. That view is confirmed by one operator who fitted the ETTCO system to a vehicle in 1982. Peter Butt, a director of the Morris Transport Co, Sutton Coldfield, decided to try the device on a top-weight Seddon Atkinson low-loader outfit. "We ran the vehicle for five or six years, and the tyre device never gave us a moment's trouble," he says. "One set of tyres gave us over 100,000 miles."

The company has not fitted any further ETTCO monitors. "It was around the beginning of the recession, and we couldn't honestly justify the expense on a system that was unproven — at least as far as we were concerned," says Butt. The hesitation was not purely financial. "If you've got a small, well-maintained fleet and you're scrupulous about checking tyre pressures, you shouldn't need anything else." However, Butt is more enthusiastic about the potential savings on smallwheeled low-loaders, where inner tyres are relatively inaccessible.

Larger operators with substantial maintenance resources are now beginning to take a more positive view. Lyons Tetley, for instance, fitted nearly 150 Shrader axle sets to its fleet over two years ago, and has been specifying them ever since. Big breweries such as Bass have been introducing them selectively as well.

Another operator using the ETTCO system is Yorkshire-based haulier Bayford and Co, whose group fleet engineer, Tony Wragg, is very keen. "There's no doubt that since we're been fitting the system, drivers have been keeping more of an eye on tyre pressures." he says. He has fitted the system to about 40 tractor and trailer axles in his fleet.

On heavy-duty on/off-road work with eight-wheeled tippers, the company had found that slow punctures on inner tyres were a particular bugbear. "Without any easy way to check pressures, it could be some time before they were spotted," says Wragg. "Now drivers just have to check to see if the little green man is visible."

• Warning signal

The green man is the warning signal on the Errco system — a sprung tube which extends from the body of the valve if the tyre pressure drops. On the Shrader system, different colours appear in a segmented disk on the face of the valve to indicate under or over-inflation or correct pressure.

The two systems have built-in safeguards to prevent both wheels in a pair from losing all their air. In the ETTCO, for instance, the system closes if pressure drops between 0.5 and 1 bar (7.25psi and 14.50psi) in one tyre. Both systems close immediately in the event of a puncture. Qualms on this score may have discouraged operators from experimenting with equalisation valves in the past, although with current systems they would seem to be unfounded. Tyre industry sources confirm this view. According to Bob Powell, field service manager with Uniroyal Tyres: "When you get past the problem of guarding against total deflation, there are advantages from that point onwards."

In that case, why do relatively few Dperators fit these devices? Powell takes a pragmatic view. "If you ask them, they are usually positive about the possible beiefits. But the reality is that operators lon't like any kind of additional cost even I there are savings to be made."

II Industry statistics

['his indifference is confirmed, in his view, )y industry statistics which suggest that is many as 90% of operators do not keep :omprehensive tyre records. "How can rou prove the benefits to operators when hey don't know what tyres are costing hem now?" he asks.

Not that experience with equalisation ralves is perfect. According to Richard F.dy, director of the National Tyre Distrixitors' Association, there can sometimes )e problems when tyre fitters at a road;ide repair are confronted unexpectedly with one of these devices. "They need :areful treatment, otherwise there's a risk damage." In any case, says Edy, these levices are still relatively rare.

Meanwhile, a more high-tech approach o tyre pressure monitoring could soon ead to new developments. The ideal is to Kovide an in-cab warning of low tyre wessure, and there have already been ;everal attempts to achieve this. One ;uch device, on sale in Britain in the mid!ighties, was called the TRAK (Tyre Risk kdviser Kit), and incorporated a batteryiowered micro transmitter fitted to the wheel. This was linked to the valve, and ,earned a warning to a cab unit if there was a pressure loss.

Midlands haulier S Jones (Aldridge) ried one on a tri-axle trailer with wide single tyres, but the company found it suffered interference from CB radio, and also seemed to be affected by overhead cables and radio transmission stations on the route.

A new contender for this market has now emerged from Liquid Levers, a Cupar, Fife-based garage equipment specialist headed by inventor Nigel Buchanan. Different technology has been used; the device incorporates a miniature printed circuit board and crystal power source on the wheel itself, with its aerial wound into the connecting hose. The sensor monitors both tyre pressure and temperature.

The device also incorporates an equalisation valve, which puts it in contention for the twin-wheel market. According to Buchanan, so much interest was aroused by demonstrations at last year's Motor Show that a well-known multinational company is now backing it.

The idea of monitoring both pressure and temperature has also been adopted by Michelin for its MTM (Michelin Tyre Monitor) system — a device aimed at private cars, but with the potential for truck applications. This is strictly an original-equipment system, requiring special road wheels to accommodate the sensors. Again, it transmits tyre pressure and temperature information to a dashboard display. The system was used successfully by Peugeot Talbot during the last Paris-Dakar rally.

Pressure on car manufacturers to fit such devices is growing with the development of run-flat tyres.

It is important that motorists using these tyres should know when there has been a puncture and avoid abusing the tyre by continuing to drive on it. This need may well produce further sensor systems that could have equal benefits for truck operators, but it could take time.