• A FOUR-CYLINDER EIGHT-PISTON ENGINE.

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

Details of an Interesting Engine which has Been Designed Primarily for Heavy Fuels.

IN SPITE OF the fact that the internal-comiaustion engine is the most efficient form of power producer -known, the thermal efficiency of even this type of engine as applied to motor vehicles is only something in the neighbourhood of 25 per cent., that is to• say, that 75 per cent. of the total heat of the, fuel is wasted, We do not cool a petrol engine because we want to ; it is necessary because the engine will not work efficiently, and is liable to,seize up, unless the heat of the working parts he kept below a level at which lubrication is effective. If, however, more of the heat contained in the fuel could be employed to produce power without heating unduly the working parts, and without increasing greatly the difficulties and expense of manufacture, this would be a decided a.d.vantage.

• The heat of combustion in a petrol engine is approximately 3,000 degrees F., that is to say, above the melting point of cast-iron, and the greater the difference between the temperatures of two materials in contact, the greater is the loss of heat from the material at. the higher temperature. The loss of heat is also directly proportional to the, area in contact with the burning fuel, and it is well known that the pressure and temperature in an engine with an approximately spherical combustion chamber are higher than when the combustion chamber is of the usual Shape; also if the area of the water-cooled surface exposed to the burning gases can be reduced, the temperature losses can also be reduced, as the •heat in then absorbed chiefly by the pistons, which, being at a higher temperature than the walls of the cylinder' do not absorb the same amount of heat.

An interesting engine called the Jackson, which was shown recently at the National Truck Show at .Chicago and manufactured. by the Petroleum Motors Corporation, of Chicago, has been designed with a view to reducing so far as possible the heat losses. This engine operates on the ordinary four-stroke cycle principle, but it embodies sueh novel features that we will not apologize for including a detailed • description in our columns.

At first sight it appearssimilar to the old GobronBrillie engine with its opposed pistons. This French engine was, however, designed under the erroneous impression that more power could be obtained by replacing the, head of each cylinder by a piston, no attention being paid to the fact that. the gases press

ing against the cylinder head in the ordinary type ol engine would reaa on the piston and therefore perform the same, useful work without the extra frictional losses caused by the multiplication of pistons and connecting rod bearings.

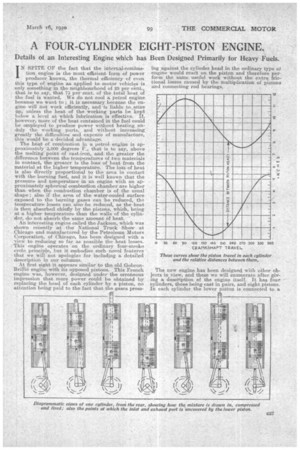

The new engine has been designed with Other objects in view, and these we will enumerate after giving a description of the engine itself. It has four cylinders, these being oast in pairs, and eight pistons. In each cylinder the lower pieton is connected to a

crank with a throw of 5 ins., whilst, the upper piston, which has .a very long connecting rod, is connected to a crank with a, throw of 4 ins., and separated from the former crank by an angle of 90 degtees, so that the lower piston is always this much in advance of the upper. In addition to this the cylinders are off set by in., this offsetting being in the opposite direction to that employed in many other engines in eider to reduce side thrust on the walls of the cylinders during the working stroke. The pistons in neighbouring cylinders work together, and the two upper pistons of each cylinder block are connected to the crankshaft by two long connecting rods, the pistons themselves Working on a connecting shaft which acts as a, gudgeon pin. The beige connecting rods operate in a channel which is in direct communication with the crankcase, and they are thus lubricated by oil mist, which, incidentally, also lubricates the upper pistons. In the particular engine which was exhibited the magneto. is contained in the space between the two cylinder bloekeeand driven by a vertical, skew gear from the camshaft. In each cylinder the port. which communicates with the inlet and exhaust valves is covered by the lower piston when this is at the upper end •of its travel, and is not uncovered until the piston has descended for some little distance.

The diagrammatic views of the piston action in a single cylinder, which we reproduce, will render the working of this engine clearer to our readers. ,Iii the first. is shown the beginning of the inlet stroke. As the lower piston is nearing the top of its stroke it is travelling-slowly, whilst the upper piston, which has just passed its bottom dead centre, is rising rapidly, thus both are moving in the same direction, but are separating, with the result that the air or mixture between them is highly raxified. The continuation of this operation is shown in the second diagram, whilst the third shows the uncovering of the port, after which the inlet valve is opened, and the mixture from the carburetter rushes into the space between the pistons. The fourth diagram shows the beginning of -the compression stroke ; the pistons are travelling towards each other. In the next diagram the point at which combustion takes. place is about to be reached. It will be noted that at this point most of the work of turning the crankshaft is being done by the. utsteer piston, and this continues until the lower piston is well over the top dead' 'centre, when the lower piston begins its work. Before this is quite complete, the upper piston begins to descend, but very slowly, meanwhile the lower c28

piston .uncovers the port., and shortly after this the exhaust valve is opened and the two pistons converging force out the burnt gases. The motions-of the two pistons can be clearly seen from the motion curves which we reproduce. • The offsetting of the cylinders has a somewhat

• curious effect on the various strokes ; for instance, the inlet and power strokes are completed in approximately 165degrees of crank motion, whilst the compression stroke corresponds to a crank motion of approximately 195 degrees, so that the former two strokes are made in approximately 15 per cent less time than the latter, in ether words, the speed of expansion of the burnt gases is increased by that amount; this would appear to be eminently satisfactory, but is not quite so in reality, as the increased piston speed occurs chiefly towards the end of thestroke, instead of at the beginning, where. the cooling effects are more important. The combined travel of the two pistons is 9 ins., but the effective stroke, which is the difference between the maximum and minimum differences apart of the two pistons, is only 6a ins., owing to the fact that the motions of the two pistons overlap. Owing to the offsetting of the cylinders being in the -bpposite direction to that which is wally employed in other engines, the side thrust of the pistons on the cylinder walls during the power strokes is increased rather than decreased, and it is questionable whether this disadvantage is counterbalam!ed by the slight gain due to the increased piston speed during the power stroke. As each piston head is concave., and the two pistons at the moment of ignition are dose together, the combustion chamber is pra.ctically spherical, and the cylinder wall area exposed is reduced to the minimum. In the engine which we illustrate the sparking plug is shown projecting into the centre of the combustion chamber. This would apparently cause difficulties, owing to pm-ignition, as the heat at the sparking plug points, practically all of which has to be conveyed away by the body of the plug, has an abnormal distance to travel. It would also appear somewhat difficult to obtain the high compression which is required for the heavy fuels which this engine is primarily designed to use. It is stated that the fuel is ,vaporized in an ordinary carburetter, and apparently relianceis placed upon the high degree of vacuum obtained daring the inlet stroke, and the consequent rapid rush of air through the carburetter to vaporize and break up the fuel.