There's more to

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

Temperature Control

than meets the eye

By Paul Brockington M.I.Mech E

Good engine cooling may depend on a variety of external factors that include the provision of a coolant conditioner, the design of the radiator and the use of a variable drive fan and /or radiator shutters. Encapsulation of the engine to reduce noise would create major cooling problems.

CONDITIONING the coolant is a subject that has received scant attention from most operators. Cummins and the Detroit Diesel division of General Motors point Out that employing a multi-purpose conditioner that acts as a water softener, controls corrosion and provides mechanical filtration assists in increasing the efficiency of the unit by eliminating deposits that impair heat transfer. Its use also reduces maintenance.

Detroit Diesel says limitation of maximum outlet temperature to 200 degF is necessary to avoid oxidation of the lubricating oil, the temperature of which is normally about 35deg F to 45deg F above the coolant outlet temperature. Of particular interest with regard to installation problems, Detroit Diesel points out that there is an optimum length of fan-to-radiator shroud, and that the tendency to reduce the overall length of the engine/radiator package to a minimum may reduce the length below the optimum with a consequent loss in fan . efficiency, particularly when fans of small diameter are used.

The larger the diameter of the fan, the greater is its effectiveness on account of the increased core coverage provided and the bigger exit area, which is specially important in the case of V engines because of their large frontal area. A reduction in air flow is cited as a more serious fault than a proportionally similar reduction in coolant flow.

It is noted by Detroit Diesel (as well as Cummins) that a pressurized cooling system improves the performance of the coolant pump because of the increased pressure on the suction side of the pump. It is also said that pressurizing can ensure against loss of coolant resulting from after-boil. A combination ,filler

cap /pressure-relief valve is criticized on the score that it cannot have a dual function "without compromise". A separate pressure relief valve is recommended.

Continuous coolant aeration with an open or closed thermostat and near-maximum pump flow with a closed thermostat are included in the Detroit Diesel "optimum cooling system design". A fan parasitic load of not more than 4/5 per cent of engine load is also a requirement of the system, and it is said to eliminate the need for radiator shutters. A thermostatically controlled fan is recommended for a system with a parasitic fan load of more than 4/5 per cent.

Future development

Enclosing the engine in a sound-proof compartment and utilizing a cooling pack above or behind the vehicle cab was mentioned as a probable future development by Ronald Whiteside. director and chief engineer of Rolls-Royce Motors

Diesel Division, in his paper on the effects of legislation on engine design read at the CM Fleet Management Conference in September last year.

Mr Whiteside envisaged a compartment with strategically placed openings having sound-absorbing splitters that was directly cooled by a small fan. The radiator would be located as high as possible above the ground and cooling air would be discharged vertically, together with the exhaust gas, which would be diluted by the air. Fan ducting would be lined with sound-absorbing materials.

In an application to a van the pack could provide an extension of the body to the front of the cab. which would minimize air recirculation and reduce wind resistance. The fans would be of the temperaturemodulated type driven by electric or hydraulic motors.

BLMC also forecast the advent of engine encapsulation to . reduce noise, first to pay and later to goods vehicles, and said that cooling packs will be developed to cater for enclosed engines, which will be mounted, in some cases, remote from the engine. Provision is being made on Leyland vehicles for the optional fitting of radiator shutters,

which are cited as a necessity for psv to provide heat for the driver and passengers. While agreeing with Rolls-Royce that shutters can cause fan flutter and eventual failure. Leyland says that blades can be produced which are proof against flutter. Company technicians claim that shutters reduce fan power when shut, and point out that they also reduce direct cooling of the block, which can overcool the oil.

While a noted radiator specialist cites the development of fin-and-tube radiator blocks having louvred fins as an important design trend in that it enables heat dissipation from a block of a given thickness to be increased, BLMC considers that radiators have reached finality in design. The corporation agrees with this specialist, however, that after-boiling is a problem in the UK as well as hotter countries. Pressurization and ample cooling system capacity are claimed to cope with after-boil problems, but it is notable that Dynair Ltd, of Nailsworth, Glos, was recently asked by a well-known engine maker to develop a post-operational circulation system that would continue to circulate the water after the engine had stopped to simulate running the engine at a tick-over speed for some time before shutting down. This normally prevents after-boil.

Of special interest to operators of wet-linered engines that have suffered from cavitation erosion, British Leyland says that ample water flow round the bore can reduce or eliminate erosion. The Leyland 500 has cross-flow cooling of each cylinder which promotes uniformity of cooling throughout the block.

A cv first?

The declared intention of Clayton Dewandre to develop a variable-delivery oil pump to actuate the hydraulically driven fan motors of the company's Compas psv system could be of first importance because the application would be the first of its kind to a commercial vehicle in this country, and it could well be applied (as mentioned by Mr Whiteside) to a cooling pack.

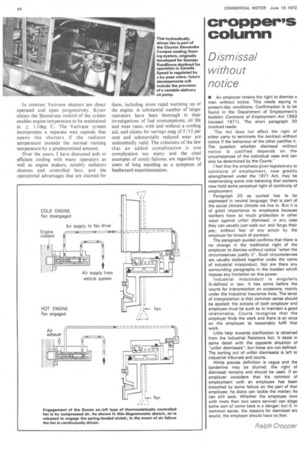

Variable drive of the fans is currently provided by a thermostatically controlled bypass valve and it is notable that auxiliary radiators with electrically driven fans have been fitted to Compas Phase I systems of Daimler Roadliners operating in Canada to cater for the higher ambient temperatures. It will be recalled that the normal forward-mounted engine radiator is replaced by two still-tube radiators located under the floor with side air intakes and that the system provides saloon heating and ventilating as well as engine cooling.

A high rate of water flow through the engine reduces engine temperature gradients: radiator temperature is entirely governed by variations of air flow (which is claimed to be favourable to reducing the gradient) and the side intakes obviate cooling by ram air which can vary unpredictably.

Forty-five vehicles having .Phase I systems (without the Canadian modifications) are being operated by St Helens Transport and a prototype Phase II system is installed in a Bristol RELL bus operated by Eastern Counties. In this system the radiators are fed with ambient air at all times; in the earlier system reversal of the fans enabled air from the saloon to be fed to the radiator.

Although a variable-speed fan drive, controlled thermostatically, may be cited as the ideal, Dynair says that it is an unnecessary and costly complication. The Dynair mechanically driven fan is engaged by compressed air at a predetermined water temperature and if the air supply fails the drive remains engaged.

A viscous fan drive is a shear-type fluid coupling in which a thin film of fluid transmits the drive. Holset produces a torque-limiting type and a temperaturesensing unit, the latter being normally specified for commercial vehicles. The sensor is a bi-metallic element that controls the flow of fluid into the drive disc according to air temperature; the speed at which the drive slips depends on the area of the fluid film. A saving in fan power of 50 per cent or more is normally obtainable at higher engine speeds and a big reduction in fan noise. A torque-limiting type cuts out a big reduction in fan noise. A torque-limiting type cuts out at a predetermined speed and gives a positive reduction in maximum speed and in maximum power absorption. The use of such a unit would increase the installed rating (BS AUI41a) of the engine and thus increase the power-to-weight rating of the vehicle.

Dynair is developing a viscous drive in co-operation with a number of Continental manufacturers that could readily be adapted to coolant temperature control and claims that it has a number of advanced features. Reliability is of first importance in the operation of a fan drive and viscous fans have a favourable record of reliability. The mechanically driven fans produced by Dynair have recently been modified to dispense with an air seal and provide direct actuation of the engagement clutch.

I understand that most vehicles operating in America are equipped with radiators shutters. In this country shutters have been criticized on the score that they are easily damaged and damage can cause engine seizure. But adequate protection can readily be provided for shutters mounted in front of the radiator, and it is notable that Kysor shutters can be mounted at the rear of the radiator. These shutters are of the snap-open /snap-shut type and may be operated by an air, vacuum, hydraulic or electric actuator. In contrast Varivane shutters are direct operated and open progressively. Kysor claims the Shutterstat control of the system enables engine temperature to be maintained at + 1.5deg C. The Varivane system incorporates a separate wax capsule that opens the shutters if the radiator temperature exceeds the normal running temperature by a predetermined amount.

Over the years, I have discussed aids to efficient cooling with many operators as well as engine makers, notably radiators shutters and controlled fans, and the operational advantages that are claimed for them, including more rapid warming up of the engine. A substantial number of larger operators have been thorough in their investigations of fuel consumptions, oil life and wear rates, with and without a cooling aid, and claims for savings mpg of 5/15 per cent and substantially reduced wear are undoubtedly valid. The criticisms of the few that an added complication is one complication too many and the cited examples of costly failures, are regarded by users of long standing as a symptom of haphazard experimentation.