A Swede says: cab design has a long way to go

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

Scandinavian truck cabs are often held up as shining examples. Here is one report which casts some doubts.

by a special correspondent TRUCKS offer bad working conditions. This is the main conclusion of a Swedish investigation undertaken by Bengt Axelsson, safety engineer for Solidar, a co-operative company in Malmo. The study was made as examination work covering a two-year course in ergonomics, environment protection and the maintenance of employees' health — organized by the Swedish Co-operative Association in conjunction with the Institute of Working Medicine.

A poor "technical environment", says the report, affects the driver in several different ways: his health, discomfort, accidentpro neness, irritation and the need for undue exertion, the latter reflected in slow working, irrational mistakes and so on.

Noise, draughts, bad heating and wrongly designed controls are the most common causes of discomfort, but the inadequate design of cab-entry features — steps, grabs, doors — increases the driver's effort and can lead to a high rate of sickness and accidents. The investigation used a scientific approach to demonstrate what is often alleged: that trucks are on the whole badly designed working places for human beings. In many vital ways they are so bad that they directly threaten the health of drivers, the report claims.

The study included interviews with 30 drivers at the company being investigated, and the examination of their vehicles. These were the Scania LB 80s, Volvo F84 /86, Volvo F82/83, and Ford D500 and D600. The LB 80s were from 1970-1971, the .F82/83 (and Volvo L430) from 1960-1970, the F84/86 (and L475) from 1963-1971 and the Fords from 1966-67. In addition, one 1968 Scania 76 was involved, and one 1966 Scania 36.

Mr Axelsson believes the vehicle manufacturing industry has been too commercial in outlook and has not used existing ergonomic knowledge which could have led to wide improvements.

He comments: "To give the driver a correct working position in all respects and to design good control devices and

instruments does not necessitate large costs if these measures are undertaken when the product is in the process of design or new production. Obviously, the knowledge in this respect is lacking in the industry or has given way to simple and badly based sales argument".

The investigation comments on vehicle design as well as the drivers' working situations when loading and unloading. The studies were concentrated on the driving controls, heating and ventilation, noise, vibration and exhaust. Measurement and time studies were supplemented with interviews and discussions with the drivers and in nearly every case very good conformity was found between the objective and subjective characteristics.

Special studies were made of important details — one being the driving seat. Nearly all the driving seats had an excessively large seat depth. The only exception was the Ford D500. Measurements were based on figures calculated from the body structure of the average man. An excessively deep driving seat can interfere with leg movements when braking and declutching. Another important point was the entrance step, the location of which can be a vital factor regarding the strain placed on the driver's back and joints. None of the trucks checked had an entrance layout that was correctly adapted to the normal human being, says Axelsson. The first step was too high and the distance to the second was too great. The driver is therefore frequently forced to jump out of the vehicle and in doing so subjects his back to severe stresses. The same criticism applied to mounting or getting down from the load platform.

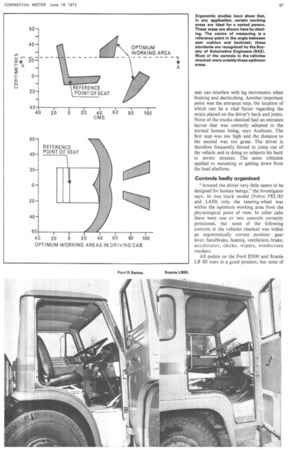

Controls badly organized "Around the driver very little seems to be designed for human beings," the investigator says. In one truck model (Volvo F82/83 and L430) only the steering-wheel was within the optimum working area from the physiological point of view. In other cabs there were one or two controls correctly positioned, but none of the following controls in the vehicles checked was within an ergonomically correct position: gear lever, handbrake, heating, ventilation, brake, accelerator, choke. wipers, windscreen washers.

All pedals on the Ford D500 and Scania LB 80 were in a good position, but none of the Volvo models in the survey were said to fulfil basic ergonomic requirements on placing. The accelerator and clutch pedals on the Ford were reckoned to have a working resistance that was above the level recommended by the international authorities.

The control symbols are also criticized by Mr Axelsson. The heating control, for example, is said to be correctly marked only on the Scania LB 80. On Volvo F82 /83 1970 symbol markings were found only on the wiper/washer control, and these did not show how the control should be moved; the symbol could be seen only if the driver opened the door and put his head outside the cab.

Tough climate Bad "climatic" conditions were mentioned as the most irritating factor by many of the drivers interviewed. In some truck models the heat through the engine cover caused annoyance and in almost all cabs there were draughts. In none of the trucks was it possible to keep the temperature of the cab at a comfortable level in warm weather. The drivers said that they had to drive with open side windows in order to keep an agreeable degree of cab comfort. In his summary, Bengt Axelsson notes that the worst climatic conditions among the vehicles tested were offered in Volvo F82 /83 and the best in Scania LB 80.

Noise risks Cab noise is also bad, says the investigator. In the Volvo F83 and Scania 76 (1968 model) the noise level was above 85 dBA which is generally considered the minimum level which should be kept down to in order to avoid potential hearing damage when subjected to noise over long periods. However, even in trucks with noise levels below the risk zone many drivers were disturbed by the noise emitted. This shows, the investigator says, that the 85 dBA is way above the comfort level.

In his comments in this chapter of the report Bengt Axelsson recommends owners of Scania 76, LB 80 and Volvo F83 to add some extra noise insulation.

The investigation covered many other points, but here are some of the conclusions summarized: El The best cab climate was offered in Scania LB 80, the worst in Volvo F82 /83 and L430.

El The drivers were exposed to exhaust fumes to the same extent in all trucks. For oil smell the same rules are valid as for cab-climate protection: bad insulation — strong smell.

El The noise level was lowest in Volvo F82 and L475 and highest in Volvo F83 and Scania LB 80 and 76.

O The best working position was offered by Scania LB 80 and Ford D500 and D600, the worst by Volvo Fs2 /83 and L430 (even those with new-design seats).

El The best driver controls were found in Scania LB 80 and Ford D models.

El Volvo F84 /86 and Scania LB 80 had the best instruments. The Ford Vehicles and Volvo F82/83 and Volvo L430 had the worst.

Bengt Axelsson says he hopes the factors highlighted in his report will lead to medical evaluations of accidents and disease symptoms among drivers, and to a new attempt to solve ergonomic problems by innovation. He looks for better contacts between ergonomists and vehicle designers and producers — and others whose work impinges on the working environment of transport employees.

And he suggests that there is much to be learned from a close comparison of existing vehicles, in particular the layout of controls and the relationship between seating and controls.