Areal cool body

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

by Paul Brockington, MIMechE

A new strength and high thermal efficiency is achieved in bodybuilding when a non-absorbent insulant is glue bonded to glassfibre and plywood sandwich sections.

AT the Commercial Motor Show at Earls Court this year a method of body construction new to the UK, will be displayed by Silverdale Motor Bodies Ltd of York Road, Birmingham. The bodies, which are claimed to give a higher thermal efficiency and are lighter than conventional bodies with a subsequent increase in payload, will be constructed on a Transit 35cwt chassis for the Show.

An all-glued frameless sandwich construction with an expanded plastic insulant — Klegecel — is the basis of the construction. By using lengths of up to 12m, it is claimed that the bodies have sufficient strength to support an overload of hanging meat without distortion and to provide weight, durability and service advantages.

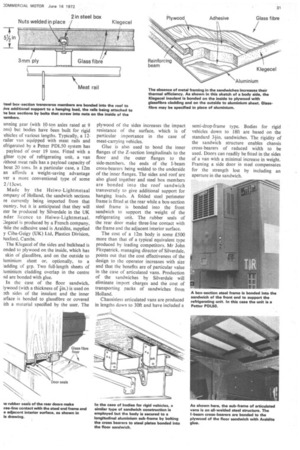

The absence of metal framing and perimeter frame increases the insulating properties of the sandwich, and it is notable that the K factor provided by the standard 3i-in. sandwich is 0.27, which compares with the European standard for frozen foods of 0.35. A favourable overall thermal efficiency is obtained despite the fact that the nominal efficiency of Klegecel is lower than that of polyurethane, which is more generally used as an insulant. While the ends of the steel I-beam cross-bearers of the articulated van sub-frames are bolted to the floor sandwich during assembly, the sole purpose of the bolts is to locate the floor and to act as clamps not as load-carrying members. The beams are glued to the lower plywood section of the sandwich and this is said to give an adhesive strength greater than that of conventional mounting with multiple bolts. Clamping bolts are also employed when assembling the sides on the steel Z-section members of the underframe and rivets are used for clamping the top capping rails and lower finishing strips. The articulated van bodies are virtually of all-glued construction apart from the sub-frame members which are welded together.

An identical form of construction has been employed by Continental bodybuilders for some years. The high thermal efficiency of the shell enables frozen food to be carried on runs up to 300 miles with one drop in an insulated vehicle without a refrigerating system. In other cases it has enabled the use of a refrigerating unit of reduced capacity.

Of special importance, Klegecel does not absorb moisture and this gives it an indefinitely long life. The one-piece sides and roof are lined on the inside with glassfibre sheet which is easy to wash and does not damage a hanging load of meat. Constructionally, the sandwich has the advantage over the moulded type in that section can be produced of any length and width with ease. Tests of body structures have included one of a 12m articulated van that normally carried a hanging load of 20

tons that was loaded to 35 tons and tilted to an angle of about 30deg. The torsional rigidity of the structure was demonstrated by the ease with which the doors of the tilted van could be opened and closed.

Initially, the company is concentrating in the main on the production of chassisless semi-trailer vans with lengths up to 40ft (I2m) with Rubery Owen widespread uniting gear (with 10-ton axles rated at 9 ons) but bodies have been built for rigid thicles of various lengths. Typically, a 12railer van equipped with meat rails and efrigerated by a Petter PDL50 system has . payload of over 19 tons. Fitted with a ghter type of refrigerating unit, a van vithout meat rails has a payload capacity of bout 20 tons. In a particular case, a 12m an affords a weightLsaving advantage ver a more conventional type of some 2 /13cwt.

Made by the Heiwo-Lightmetaal ompany of Holland, the sandwich sections re currently being imported from that ountry, but it is anticipated that they will 'ter be produced by Silverdale in the UK nder licence to Heiwo-Lightmetaal. :legecel is produced by a French company, ,hile the adhesive used is Araldite, supplied y Ciba-Geigy (UK) Ltd, Plastics Division, /uxford, Cambs.

The Klegecel of the sides and bulkhead is onded to plywood on the inside, which has skin of glassfibre, and on the outside to luminium sheet or, optionally, to a ladding of grp. Two full-length sheets of luminium cladding overlap in the centre ad are bonded with glue.

In the case of the floor sandwich, lywood (with a thickness of .in.) is used on oth sides of the insulant and the inner 'dace is bonded to glassfibre or covered ith a material specified by the user. The plywood of the sides increases the impact resistance of the surface, which is of particular importance in the case of meat-carrying vehicles.

Glue is also used to bond the inner flanges of the Z-section longitudinals to the floor and the outer flanges to the side-members, the ends of the I-beam cross-bearers being welded to the underside of the inner flanges. The sides and roof are also glued together and steel box members are bonded into the roof sandwich transversely to give additional support for hanging loads. A folded steel perimeter frame is fitted at the rear while a box-section steel frame is bonded into the front sandwich to support the weight of the refrigerating unit. The rubber seals of the rear door make three-line contact with the frame and the adjacent interior surface.

The cost of a 12m body is some £500 more than that of a typical equivalent type produced by leading competitors. Mr John Fitzpatrick, managing director of Silverdale, points out that the cost effectiveness of the design to the operator increases with size and that the benefits are of particular value in the case of articulated vans. Production of the sandwiches by Silverdale will eliminate import charges and the cost of transporting packs of sandwiches from Holland.

Chassisless articulated vans are produced in lengths down to 30ft and have included a semi-drop-frame type. Bodies for rigid vehicles down to 18ft are based on the standard 34in. sandwiches. The rigidity of the sandwich structure enables chassis cross-bearers of reduced width to be used. Doors can readily be fitted in the sides of a van with a minimal increase in weight. Framing a side door in steel compensates for the strength lost by including an aperture in the sandwich.