Factors in Air and Oil Filtration

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Some Notes Arising From a Visit to the Vokes Exhibition of Special Equipment

9fTHERE have been all sorts of HERE concerning the reasons for wear in engines which might be considered in excess of that due to the normal rubbing friction between pistons and cylinders, bearings and their shafts, valves and their guides, and the teeth of timing gears.

For quite a long period much of the loss of life thus occasioned in these various components and, consequently, in the power unit as a whole, was attributed by experts to the effects of chemical corrosion. Since then, however, most careful researches have been carried out, and this theory has been practically rebutted, the main cause of wear now being blamed upon the abrasion of the surfaces by particles of matter, many of which have " cutting " attributes, contained in the air drawn into the cylinders and which eventually find their way into the oil.

The problem of obviating such excess wear has, therefore, to be tackled from two sides. Dust and other particles suspended in the air must, so far as possible, be eliminated, whilst the lubricating oil requires most efficient filtration constantly to remove gritty and other material which may affect the bearing surfaces or clog the oil ways. With new engines, there is another problem, that is, to remove deleterious material, such as foundry sand, from the castings, and dirt which has become embedded in bearing surfaces during manufacture.

An example of the latter trouble has been referred to by Mr. C. G. Yokes, A.M.I.Mech .E., A.F .R.Ae. S. ,M.I.A. E., M.S.A.E., managing director of Vokes, Ltd., Guildford, Surrey.

Dirt From New Engine Following .a test-room experiment with a new aero-engine, which was run for many hours non-stop, with'a specially designed and oversize filter, it was found that 5 lb. of dirt and sludge had collected in the filter. This despite the fact that every possible precaution had been taken to clean the engine, also the various parts, and to see that the atmosphere was normally clear.

It will be realized that such a result applies equally to any form of power _unit, although, of course, to a degree corresponding with its size.

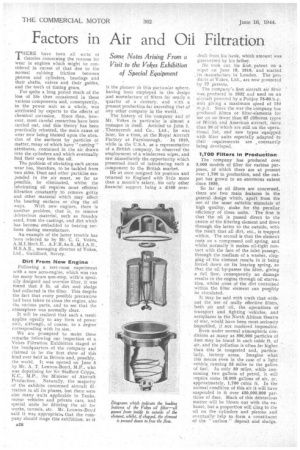

We are prompted to make these remarks -following our inspection of a Yokes Filtration Exhibition staged at the headquarters of the company and claimed to be the first show of this kind ever held in Britain and, possibly, the world. It was opened on June 5 by Mr. A. T. Lennox-Boyd, M.P., who was deputising for Sir Stafford Cripps, K.C., M.P., the Minister of Aircraft Production. Naturally, the majority of the exhibits concerned aircraft filtration in all its phases, but there were also many units applicable to Tanks, motor vehicles and private cars, and special units for filterirr, the air for works, tunnels, etc. Mr. Lennox-Boyd said it was appropriate, that the company should stage this exhibition, as it

is the pioneer in this particular sphere, haying been employed in the design and manufacture of filters for nearly a quarter of a century, and with a present production tar exceeding that of any other company in the world.

The history of the company and of Mr. Yokes in particular is almost a romance in itself. Articled to John 1. Thornycroft and Co., Ltd., he was later, for a time, at the Royal Aircraft Factory at Farnborough. In 1919, while in the U.S.A. as a representative of a British company, he observed. the employment of a windscreen wiper, and saw immediately the opportunity which presented itself of introducing such a component to the British market.

He at once resigned his position and returned to England with little more than a month's salary, his only other ,financial support being a £100 over

draft from his bank, which amount was guaranteed by h.s father.

Ile took out his first, patent on a wiper on June 19, 1919, and started , its manufacture in London. The pro-. ducts of Yokes, Ltd., are now protected by 77 patents.

The company's first aircraft air filter was, produced in 1932 and used on an aircraft powered by a Pobjoy 75-80.h.p. unit giving a maximum speed of 150 m.p.h. Since the war the Company has produced Eters or filter-elements for use on no fewer than 87 different types of British and American aircraft, more than 50 of which are still on the operational. list, and new types equipped ith filter units especially adapted to their requirements are constantly being developed, 1;700 Filters in Production

The company has produced over 3,000 models of filter for various purposes, of which there are at present over 1,700 in production, and the output has grown to an enormous extent since 1939.

So far as oil filters are concerned, there are two main features in the general design which, apart from the use of the most suitable materials of high quality, make for the peculiar efficiency of these units. The first is that 'the oil is passed direct to the centre of the filtering element and flows through the latter to the outside, with the result that all dirt, etc., is trapped within. The second is that the element rests on a compressed coil spring, and whilst normally it makes oil-tight contact with the face of the inlet passage. through the medium of a washer, clogging of the element results in it being forced down on its bearing spring, so that the oil by-passes the filter, giving a full flow, consequently no damage results to the engine through oil starvation, whilst none of the dirt contained within the filter element can possibly be circulated.

It may be said with truth that without the use of really effective filters, both air and oil, the operations of transport and fighting -vehicles, and aeroplanes in the North African theatre of war, would have been most seriously imperilled, if not rendered impossible.

Even under normal atmospheric conditions as many as 300,000 particles of dust may be found in each cubic ft. of air, and the pollution is often far higher than this in congested and, particularly, factory areas. Imagine what this means even in the case of a light vehicle. running 25 miles to the gallon of fuel. In -only 50 miles, while consuming two gallons of petrol, it will require some 18,000 gallons of air, or. approximately, 1,700 cubic ft. In the normal condition of this air it will have suspended in it over 450,000,000 particles of dust. Much of this deleterious matter will be blown out with the exhaust, but a proportion will cling to the oil on the cylinders and pistons and eventually help to form a constituent of the " carbon " deposit and sludge.