Unusual Features in Girling Hydraulic Brake Control A Combination of

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

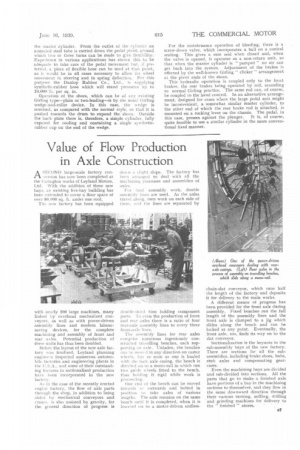

Hydraulic and Achanical Brake Control Which Provides Against all Eventualities of Brake Failure. Ingenious Unit Construction of Master Cylinder and Brake RETAINING all the " inside the brake drum " features which have contributed so much to Girling success in the past few years, New Hudson, Ltd., Icknield Street, Birmingham, producer of this equipment, has evolved an ingenious method of operating these brakes. The present scheme provides hydraulic control for one axle and the usual Girling mechanical operation for the other. Although it is likely to find its principal application in the private car, it is suitable also for certain types of commercial vehicle.

In this hydraulic system there are several unusual features. For example, it includes not a single piece of natural rubber. Some parts are of synthetic rubber, which is not affected by mineral oil, but the pressure seal on the plunger of the master cylinder is entirely metallic. It con ne

sists, in effect, of a small piston ring which is held lightly against the end of the plunger by a compression spring. and is subjected to the hydraulic pressure within the cylinder in such a way as to press it more firmly on to the plunger and to expand it against the wall of the cylinder.

On test, one of these units has held, for 27 hours, a pressure much higher than is used in normal operation. Moreover, any fluid which does leak past the plunger is not lost but is returned to the supply reservoir.

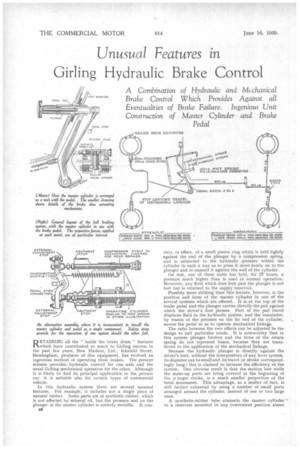

Possibly more striking than this feature, however, is the position and form of the master cylinder in one of the several systems which are offered. It is at the top of the brake pedal and the plunger carries directly the pad against which the driver's foot presses. Part of the pad travel displaces fluid in the hydraulic system, and the remainder. by reason of the pressure on the far end of the cylinder, moves the pedal so as to operate mechanical linkage.

The ratio between the two effects can be adjusted in the design to suit particular needs. It is noteworthy that in this system plunger friction and the force of the return spring do not represent losses, because they are transferred to the application of the mechanical linkage.

Because the hydraulic plunger is directly against the driver's foot, without the interposition of any lever system, its diameter can be small and its travel or stroke correspondingly long; this is claimed to increase the efficiency of the system. One obvious result is that the motion lost while the make-up ports are being covered at the beginning of the p-unger stroke, is a much smaller proportion of the total movement. This advantage, as a matter of fact, is still further enhanced by using a number of small ports arranged around the cylinder, instead of one or two large ones.

A synthetic-rubber tube connects the master cylinder to a reservoir mounted in any convenient position above

the master cylinder. From the outlet of the cylinder an annealed steel tube is carried down the pedal pivot, around which two or three turns can be made to give flexibility. Experience in various applications has shown this to be adequate to take care of the pedal movement but, if preferred, a piece of flexible hose can he used at that point, as it would be in all cases necessary to allow for wheel movement in steering and in spring deflection. For this purpose the Dunlop Rubber Co., Ltd., is supplying synthetic-rubber hose which will stand pressures up to 10.000 lb. per sq. in.

Operation of the shoes, which can be of any existing Girling type—plain or two-leading—is by the usual Girling wedge-and-roller device. In this case, the wedge is reversed, as compared with the normal style, so that it is pushed towards the drum to expand the shoes. Outside the back plate there is, therefore, a simple cylinder, fully exposed for cooling and containing a single syntheticrubber cup on the end of the wedge. For the maintenance operation of bleeding, there is a screw-down valve, which incorporates a ball on a conical seating. This gives a sure seal when closed and, when the valve is opened, it operates as a non-return unit, so that when the master cylinder is " pumped" no air can get back into the system. Adjustment of the brakes is effected by the well-known Girling " clicker" arrangement at the pivot ends of the shoes.

This hydraulic operation is coupled only to the front brakes, the rear brakes being operated by rod, according to normal Girling practice. The same rod can, of course, be coupled to the hand control. In an alternative arrangement, designed for cases where the large pedal unit might he inconvenient, a somewhat similar master cylinder, to the other end of which the rear brake rod is attached, is mounted on a rocking lever on the chassis. The pedal, in

this case, presses against the plunger. It is, of course, quite feasible to use a similar cylinder in the more conventional fixed manner.