Road Test No. 149

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

SENTINEL STEAMER

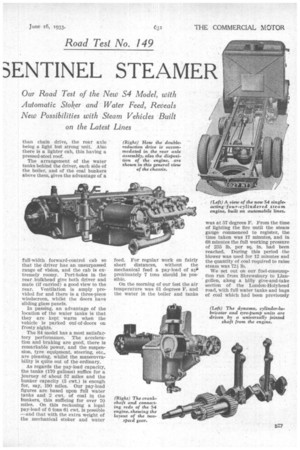

than chain drive, the rear axle being a light but strong unit. Also there is a lighter cab, this having a pressed-steel roof.

The arrangement of the water tanks behind the driver, each side of the boiler, and of the coal bunkers above them, gives the advantage of a full-width forward-control cab so that the driver has an unsurpassed range of vision, and the cab is extremely roomy. Port-holes in the rear bulkhead give both driver and mate (if carried) a good view to the rear. Ventilation is amply provided for and there is a three-piece windscreen, whilst the doors have sliding glass panels.

In passing, an advantage of the location of the water tanks is that they are kept warm when the vehicle is parked out-of-doors on frosty nights.

The S4 model has a most satisfactory performance. The acceleration and braking are good, there is remarkable power, and the suspension, tyre equipment, steering, etc., are pleasing, whilst the manmuvrability is quite out of the ordinary.

As regards the pay-load capacity, the tanks (170 gallons) suffice for a journey of about 57 miles and the bunker capacity (5 cwt.) is enough for, say, 190 miles. Our pay-load figures are based upon full water tanks and 2 cwt. of coal in the bunkers, this sufficing for over 70 miles. On this reckoning a legal pay-load of 6 tons 61 cwt. is possible —and that with the extra weight of the mechanical stoker and water feed. For regular work on fairly short distances, without the mechanical feed a pay-load of alft proximately 7 tons should be possible.

On the morning of our test the air temperature was 61 degrees F. and the water in the boiler and tanks was at 57 degrees F. From the time of lighting the fire until the steam gauge commenced to register, the time taken was 17 minutes, and in 68 minutes the full working pressure of 255 lb. per sq. in. had been reached. During this period the blower was used for 12 minutes and the quantity of coal required to raise steam was 721 lb.

We set out on our fuel-consumption run from Shrewsbury to Llangollen, along a hilly give-and-take section of the London-Holyhead road, with full water tanks and bags of coal which had been previously weighed. The return journey of 58.8 miles was all but completed on the supply of water, whilst 173 lb. of Windber steam coal was consumed.

After driving quite a short distance we realized that when not hauling the trailer it was unnecessary to maintain a steam pressure of 255 lb. and, in practice, our log shows that pressure ranged between 140 lb. and 234 lb., the needle generally remaining in the region of 190 lb.

This gave more than enough power for legal speeds, even up quite steep gradients, and the lower gear was never required even for restarting on a severe incline. Indeed, the rear and middle cut-off positions were necessary for only the first few seconds after starting on the level and the acceleration to 30 m.p.h. was surprisingly good.

On a normal road the vehicle cruises with ease at 30 m.p.h. and on a straight, level road it will do about 40 m.p.h. We mention these figures as indicative of. the capabilities if a trailer were drawn.

We did not have an opportunity of testing the vehicle with a trailer up the well-known Harley Bank, on the Shrewsbury-Bridgnorth road, which is about a mile long and has a gradient of approximately 1 in 8, increasing to 1 in 6 at the crest, but we are told that with a gross weight of 211 tons, and using the low gear, the outfit has made this ascent at about 8 m.p.h. on the early cut-off position except for the 1-in-6 section.

Several gradients in the order of 1 in 15 were climbed in the course of our day and the gross weight of 13 tons was at all times within the top-gear capabilities of middle cutoff position.

The two-wheel brake system is simple and robust, resembling that on the Lightweight model, which we found to be remarkably efficient. The brake readings are shown in the B28

Above appears a graph giving the results obtained in our braking tests of the Sentinel S.4. vehicle fully laden to 13 tons. It will be seen that improved braking results from supplementing the steam brake with the hand-applied set.

The above graph shows the rapid acceleration of the laden Sentinel. There is, of course, no change of gear, the higher gear sufficing

for all ordinary work. accompanying graph, and indicate that the best results are obtained when the hand brake and steam brake are applied together.

As regards the handling of the vehicle, we found this probably the most satisfying feature of its road performance, for there is masterly control when the outfit is travelling at a crawling pace, such as when it is baulked by traffic in the course of a steep climb.

When reversing and mancenvring in yards the vehicle has a facility which strikes the motor-lorry driver as uncanny for, of course, there is no clutch to bother about and steam can be admitted to the cylinders in the very smallest quantity, giving the "standstill pull" which makes the steam wagon so useful for extricating itself from soft ground, such as is met with in sandpits, where many of these vehicles work. The acceleration, too, is most useful in traffic, as we found in the congested streets of Shrewsbury.

Reference to the accompanying graph affords evidence of its marked accelerative powers. Speed is gathered without pause, through the range, and there is remarkable power at the moment of starting.

The automatic stoker eliminates both labour and dirt and Positively calls for no supervision, except that there is an adjustment lever for suiting the fuel feed to the quality of the coal or the nature of the work. Briefly, the feed is effected by a screw carried in a case horizontally from the hopper base of the bunker to the firing chute of the boiler. This screw is turned by the pawl and ratchet from a worm reduction gear on the engine. An important and patented feature of the system is that the fuel feed is automatically proportioned to the water supply, the two being synchronized so that the wagon may be run continuously without any need for looking at the fire.

One reason for the economical fuel consumption is that the standard boiler has large water tubes and double superheater coils which provide a uniform degree of superheating at both low and high outputs.

In conclusion, the engine is most accessible and can easily be lowered for removal, whilst access is obtained by a floor trap-door above, it. The rear-axle differential and double-reduction gear may be examined through inspection doorways, or withdrawn after removing the axle rearward.