Recovery positions

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

Boniface can tackle any task when it comes to building and speccing bespoke bodies, which has helped it rise to the top of the recovery vehicle tree.

Words / !moor-rnlin Barnei Thetford in Norfolk isnot just the UK home of Spam, but, tucked away at the back of one of the town's industrial estates, just off today's All, it is also the location for the base of Boniface, probably the UK's largest manufacturer of recovery vehicles. The sprawling layout is a sign of how the firm has expanded over the years, repeatedly taking over the premises next door. It has yet another plot levelled, ready for a further workshop.

The company was set up in 1982 by today's MD, Mike Boniface, who was a former Dennis apprentice, but since 1996 it has operated as a standalone division of Miller Industries of Ooltewah, Tennessee.

Miller Industries also has a French subsidiary, Jige International, from Revigny-sur-Ornain in Champagne country, which looks after its home market, but the rest of Europe and China, via Hong Kong. is Boniface export territory. Thanks to the present poundieuro relationship, some 30% of Boniface production is exported to all of Europe, except France, and increasingly to the Far East. When we visited, Mike Boniface was leading a sales team at a major trade show in Germany At home, the recovery market has changed significantly over the past 10 years. Back then, 80% of output involved conversions on used chassis, but today. 90% is brand new. UK sales are direct from factory to operator, although eight service agents around the country and a £2m central spares stock provide backup. Compared with sales of new Boniface products, the throughflow of used vehicles is surprisingly low. Many operators work old trucks to the point where their used value is relatively low so they tend to hang on to them rather than part exchange. However. there's still a fair bit of work transferring old bodies to new chassis.

One issue affecting Boniface as much as any specialist bodybuilder is the imminent arrival of Whole Vehicle Type Approval. According to sales manager John Coldwell. this is likely to prove less of a threat than first expected, although he has concerns over enforcement, especially since he feels there are still recovery vehicles being sold without the currently required CE approval.

Boniface already employs a full-time compliance engineer as part of its BS 7901 accreditation. When it comes to operating legislation, recovery operators get a relatively easy ride with no plating or annual test required, just a voluntary roadworthiness certificate. Coldwell favours keeping this situation as it gives operators some essential flexibility over weights that could be lost with a rigidly enforced plating certificate in the cab.

Professional image

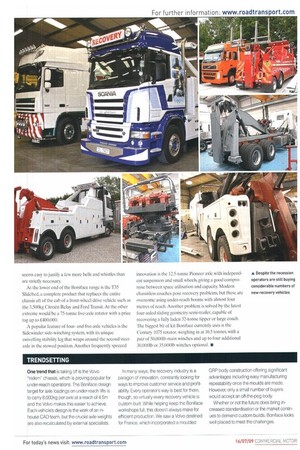

Despite the recession, operators are still buying considerable numbers of new recovery vehicles, although many tend to keep a tighter rein on specification. However, if you're spending a third-of-a-million pounds on a truck that's due for a long and high-profile working life, in an industry where a professional image is an asset, it still seems easy to justify a few more bells and whistles than are strictly necessary.

At the lower end of the Ron iface range is the T35 Slidebed, a complete product that replaces the entire chassis aft of the cab of a front-wheel drive vehicle such as the 3,500k g Citroen Relay and Ford Transit. At the other extreme would be a 75-tonne live-axle rotator with a price tag up to £400,000.

A popular feature of fourand five-axle vehicles is the Sidewinder side-winching system, with its unique swivelling stability leg that wraps around the second steer axle in the stowed position. Another frequently specced innovation is the 12.5-tonne Pioneer axle with independent suspension and small wheels, giving a good compromise between space utilisation and capacity. Modern chassisless coaches pose recovery problems, but these are overcome using under-reach booms with almost four metres of reach. Another problem is solved by the latest four-wded sliding geometry semi-trailer, capable of recovering a fully laden 32-tonne tipper or large coach. The biggest bit of kit Boniface currently uses is the Century 1075 rotator, weighing in at 16.5 tonnes, with a pair of 50,000lb main winches and up to four additional 30.0001b or 35,000lb winches optional. in