For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF 1EN SHILLINGS is awarded each week to the sender of the best letter which we yublish on this page ; all others are paid or at the rule of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The

Commercial Motor," 7-15, Rosebery Avenue, London, E.G. I.

Lamps Alight.

On Saturday, 18th January light your lamps at 4.44 in London, 5.0 in Edinburgh, 4.30 in Newcastle, 4.45 in Liverpool, 4.48 in Birmingham, 4.54 in Bristol, and 5.22 in Dublin.

Rear Axle Repair.

The sender of the following communication has been awarded the 108. prize • this week.

[1933] "W.P." (Harlesden) writes :—" A commercial traveller's car waotowed by another vehicle a few weeks ago. into our garage with the information that the engine had ceased to drive the car, although, so far as could be seen externally, everything appeared to be in order. It was quite true. that the engine could be run,'the gears engaged, and the propeller ilhaft revolved ; but the road wheels did not turn.

Retnoval of the inside hub cap exposed the cause of the trouble. The drive from the differential totthe wheels was by means of the usual pair of live axle shafts, and these shafts were splined at their outer ends, and enga,ged with corresponding castellations in the wheel hubs. In the offside wheel the castellations had sheared off, and the result was that as the propeller shaft revolved the motion was simply transmitted through the differentialito thial offside live axle, which revolved idly within its wheel.

"The car happened to be of foreign extraction : no spares were available in this countryIt would have been -practically impossible to have got a new part made, certainly not at short notice, and matters appeared at first to be at a deadlock. However, the following method of repair suggested itself,' was duly carried out, and has proved to be a success in every way.

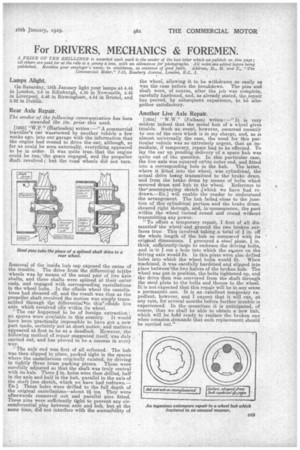

" The axle end was first of all softened. The hub was then slipped in place, packed tight in the spaces where the eastellations originally existed, by driving in tightly three brass packing pieces. These were carefully adjusted so that the shaft was truly central with its hub. Three in. holes were then drilled, half in the axle and half in the hub, parallel to the axis of the shaft [see sketch, which we have had redrawn.— En]. These holes were drilled to the full depth of the original castellations—about vi ins. They were afterwards reamered out and parallel pins fitted. These pins were sufficiently tight to prevent any circumferential play between axle and hub, but at the same time, did not interfere with the accessilility of

the wheel, allowing it to be withdrawn as easily as was the case before the breakdown. The pins and shaft were, of course, after the job was complete, carefully hardened, and, as already stated, the repair has proved, by subsequent experience, to be altogether satisfactory.

Another Live Axle Repair.

[1934] " W.W." (Fulham) writes:—" It is very seldom indeed that the metal hub of a wheel gives trouble. Such an event, however, occurred recently to one of the cars which is in my charge, and, as is almost universally the case, the need for this particular vehicle was so extremely urgent, that an immediate, if temporary, repair had to be effected. To lay the car up pending delivery of a spare hub was quite out of the question. In this particular case, the live axle was squared on'its outer end, and fitted into is corresponding hole in the hub.The latter, where it fitted into the wheel, was cylindrical, the actual drive being transmitted to the brake drum, and from the brake drum by means of bolts which secured drum and hub to the wheel. Reference to theo,aocompanying sketch ,[which we have had redrawn.—En.] will enable the reader to understand the arrangement. The hub failed close to the junction of this cylindrical portion and the brake drum, sheared right through, and, inconsequence the part ,within the wheel turned round and round without transmitting any power.

" To effect a temporary repair, I first of all dismantled' the wheel '.and. ground the two broken surfaces true. This involved taking.a total of in. off the whole length of the hub as compared with its original dimensions. I procured a steel plate, in. thick, sufficientlytlarge to embrace the driving bolts, and in-it I cut a hole into which the sq,aare on the driving axle would fit. In this plate were also drilled holes into which the wheel bolts would fit. When machined, it was carefully hardened and slipped into place betweenIthe two halves of the broken hub. The wheel was put in position, the bolts tightened up, and the drive then was conveyed from the shaft through the steel plate to the bolts and thenee to the wheel. It is not expected that this repair will be in any sense a permanent one. It is an excellent temporary expedient, however, and I expect that it will run, at any rate, for several months before further trouble is experienced. In the meantime it is anticipated, of course, that we shall be able to obtain a new hub, which will be held ready to replace the broken one when occasion demands that such replacement should be carried out."