FORD VAN POINTERS.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford ").

THERE IS A regular army of Ford rough riders— those, to wit, who never give attention to their springs. Bumpity—bunno is their lot. By springs, I mean the leaf springs fore and aft of the van. The careless driver never gives a thought to them: He goes bumping along from year's end to year's end.

Of course, it is uncomfortable for him, but he does not seem to mind that ; and I am not going to waste any pity on him.

58.—Rough Riding is Rough on the Van.

It is the van I pity—everything about it—the frame, the body, the transmission, the engine, the wheels. All these suffer from the jolt and jar produced by dry, rusty leaf springs. They suffer in silence, and so nothing is done to relieve their sufferings.

Something ought to be done. There ought to be a layer of grease between each two neighbouring leaves in the springs. Unless special precautions are taken (of which I will say more later), that layer never stops there, even when the grease has been properly applied, for any great length of time. The whole action of the springs tends to squeeze the grease out. When the grease is squeezed out, mud and wet work in, rust is set up, and the van begins to bump along instead of rolling along. When the worst happens, one of the leaves break, being eaten up with rust, and then there ii trouble, right on the spot.

There is no reason why you should not grease your own spring leaves if you can give the time to tho job ; but it takes the best par% of an hour, and you should not tackle it, therefore, unless you see yourself free of call for that length of time. Here is the way to go about it.

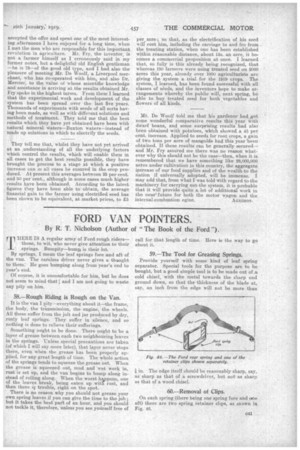

59.—The Tool for Greasing Springs.

Provide yourself with some kind of leaf spring separator. Special tools for the purpose are to be bought, but a good simple tool is to he made out of a cold chisel, with the metal towards the sharp end ground down, so that the -thickness of the blade at, say. an inch from the edge will not be more than To take the clip off, simply screw off the nut on the bolt that runs through -the clip, pull or push out the bolt, and pull the clip off downwards.

IVIaen you have a clip off, you can proceed at one to grease the leaves of the spring from middle to end, on the side where the clip was.

Having provided yourself with the spring leaf separator aforesaid, a hefty hammer, a wide knife blade, and a tin of suitable grease (of which more later), spread a sack on the ground and sit on it with your feet under the van. Take your leaf separator, and drive its edge between two neighbouring leaves, wedging them apart till you have a gap of about in. between them. Do not overdo the separation or you will unnecessarily strain the leaf : you wily want to get a gap-wide enough to enable you to insert the knife blade. Now take your broad knife blade, give it. a satisfying smear of grease, insert it between the two leaves that you have separated, and spread the grease like butter—" only more so." There is no harm in overdoing the grease supply. It is best to separate the leaves at a point near the end of the upper leaf. You will then be able to pass the knife blade from near the centre to the end of the spring. You will not be able to get it right up to the centre, but that does not matter. Get it as far up as you can, and take particular care that the end of the leaf gets well greased : that does matter.

61.—The Proper Grease.

The grease best suited to the purpose is one containing blacklead—scientifically called graphite. Special stuff is sold for the purpose. The .black grease sold for greasing bicycle chains serves well. A blaeklead lubricant acts better than anything else, but any grease will serve. 'Tallow is excellent, but rather difficult to apply, it being a bit too hard to spread when cold. Warm tallow goes in and on all right, and lasts well.

Each leaf .must be separated from its neighbour,' and grease applied as directed. This means four separate operations-7—one round each of the clips. Do not try using any wooden-handled tool for separating the leaves. You will only split the wooden handle. It needs quitea hefty blow to get the tool between theleaves, and the wood will not stand it. Do not use a finicky tool : you want one that will do the work without -bending or gapping. If you have not a screw-operated spring-leaf separator (and one is well worth buying), a ground-down cold chisel is just right.

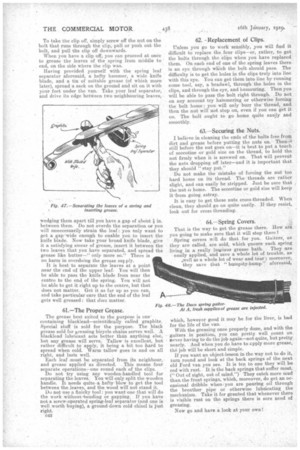

62. -Replacement of Clips. •

Unless you go to work sensibly, ,you will find it difficult to replace the four dips—or, rather, to get the bolts through the clips when you have replaced them. On each end of one of the spring leaves there is an eye through which the bolt should pass. The difficulty is to get the holes in tfie clips truly into line with this eye. You can get them into line by running some tool, say, a bradawl, through the holes in the clips, and through the eye, and humouring. Then you will be able to pass the bolt right through. Do not on any account try hammering or otherwise forcing the bolt home : you will only burr the thread, and then the nut will not stop on, even if you can get it on. The -bolt ought to go home quite easily and smoothly.

63.—Securing the Nuts.

I believe in cleaning the ends of the bolts free from dirt and grease before putting the nuts on. Then, still before the nut goes on—it is best to put a touch of seccotine or gold size on the thread, to hold the nut firmly when it is screwed on. That will prevent the nuts dropping off later—and it is important that they should " stay put." Do not make the mistake of forcing the nut too hard home on its thread. The threads are rather slight, and can easily be stripped. Just be sure that , the nut ü home. The seccotine or gold size will keep it-from going astray.

It is easy to get these nuts cross-threaded. When clean, they should go on quiteeasily. If they resist, look out for cross-threading.

64.—Spring Covers.

That is the way to get the grease there. How are you going to make sure that it will stop there I Spring covers will do that for you. Gaiters, as they are called, are sold, which ensure each spring living in a really luscious grease bath. They are easily applied, and save a whole lot of trouble, as ,well as a whole lot of wear and tear ; moreover, they save that " bumpity-bump" aforesaid, which, however good it may be for the liver, is bad for the life of the van. With the greasing once properly done, and with the gaiters in position, you can pretty well count on never having to do the job again—not quite, but pretty nearly. And when you do have to apply more grease, the job will be short and simple. If you want an object-lesson in the way not to do it, turn round and look at the back springs of the next old Ford van you see. It is ten to one they will be red with rust. It is the back springs that suffer most. (" Out of sight, out of mind.") They catch more mud than. the front springs, which, moreover, do get an occasional dribble whenryou are pouring oil through the breather pipe or otherwise lubrIcating the mechanism. Take it for granted that whenever there is visible rust on the springs there is sore need of greasing.

Now go and have a look at your own