Revolution by Stillages

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

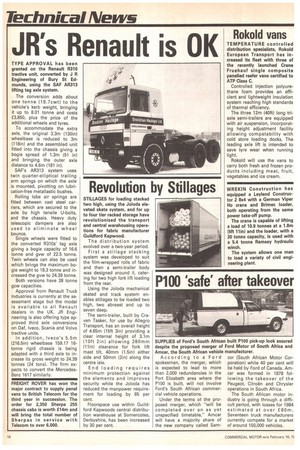

STILLAGES for loading stacked two high, using the Joloda elevated skate system, and for up to four tier racked storage have revolutionised the transport and central warehousing operations for fabric manufacturer Guildford Kapwood.

The distribution system evolved over a two-year period.

First a stillage stacking system was developed to suit the film-wrapped rolls of fabric and then a semi-trailer body was designed around it, catering for two high fork lift loading from the rear.

Using the Joloda mechanical skated and track system enables stillages to be loaded two high, two abreast and up to seven deep.

The semi-trailer, built by Craven Tasker, for use by Allegro Transport, has an overall height of 4.65m (15ft 3in) providing a clear internal height of 3.1m (10ft 2in) allowing 280mm (11in) clearance for fork lift mast tilt, 40mm (1.5in) either side and 50mm (2in) along the centre isle.

End loading requires minimum protection against the elements and improves security while the Joloda has reduced the manpower requirement for loading by 85 per cent.

Floorspace use within Guildford Kapwoods central distribution warehouse at Somercotes, Derbyshire, has been increased by 30 per cent.