A MODERN STEAMEI

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

of Light Weight for 11 -ton Pay-1

Lds

ABIG step forward in steamwagon design was made when the Sentinel Waggon Works, Ltd., Shrewsbury, introduced the Lightweight model nearly two years ago, for this employed a highefficiency, boiler working at 255 lb. per sq. in., and having water tubes of 2 ins, diameter horizontally disposed, also a double super-heater coil.

two-cylindered double-acting engine of 100 b.h.p., with mushroom valves, was fitted in that model.

About a year later, in June, 1933, we were enabled to road test the modeI-S four-wheeler, showing, again, a marked advance in design. In the model S we have shaft drive and an entirely new four-cylindered singleacting engine built on automobile principles; the result is a lower tare weight and greater pay-load, yielding improved efficiency and economy.

In the 54, which we tested last summer, the company's new automatic stoker and feed-water regulator was incorporated. This gave the impression of being a luxury in steamwagon equipment, for it removed all necessity for attention to the fire and boiler ; in fact, it eliminated the need for a second man on the vehicle. It is supplied as a standard extra fitting and there is not the slightest doubt that, despite any conservativeness amongst long-standing users of steam vehicles, it is an item of equipment that will pay for itself in many classes of operation.

This model S is the current Sentinel model and is available with four, six or eight wheels. The six-wheeler can B32 be had with either two-wheel or fourwheel drive, according to whether it is intended for road haulage of moderate severity or more arduous work on rough ground. The eightwheeler has four-wheel drive and embodies the interesting four-wheelsteering bogie which the company introduced a few years ago. Fitting eight wheels enables a legal payload of about 13 tons to be carried and, with a rigid frame, affords a high measure of road adhesion and general security.

The six-wheeler has been selected for our latest test, and in the form in which it carries the biggest and heaviest pay-load, that is, with single-axle drive, without the automatic stoker and feed-water regulator, and with the longer body usually fitted for all but tipping vehicles. In passing, it may be noted +hat the standard tipper (model S6T) has a 14-ft. 6-in, body and 13-ft. 6-in. wheelbase (to bogie centre) and an overall length of about 23 ft.

The S6 under test proved itself capable of carrying,. within the legal limit of 19 tons laden weight, a payload of 10 tons 171 cwt., as well as fuel and water for about 45 or 50 miles.. By reducing the pay-load the coal bunkers can be filled (7 cwt.), thereby increasing the fuel range to about 143 miles; but the tank capacity, in. any case, calls for a halt about every 45 miles to take on water, The chassis is built to car ry a pay-load of 14 tans, or more than 3 tons in excess of the legal pay-load, and in. overseas countries, where the company does a considerable business, the bigger loads are satisfactorily carried.

The four cylindered single-acting engine is of simple layout, and capable of being well balanced to run smoothly and quietly over a " wide range of speeds. The adoption of .trunk-type pistons, whilst lightening the engine, has permitted glands and piston-rod packing to be eliminated. The frame and shaft transmission also are commendably light.

The water tanks are located behind the driver and mate, and the bunkers are above them, so that a roomy cab is obtained, and the water is pro

tectad against frost. During our test three men were carried in the cab without undue discomfort ; the ventilation is good, and the driver has a remarkable range of vision.

On the morning in question the air temperature was 32 degrees F., and the water in tank and. boiler was at 39 degrees F. The fire was lighted, and 14 minutes later the gauge commenced to show pressure. The blower was used for four minutes, when the pressure reached 60 lb. and increased the reading to 120 lb.; 41 minutes after lighting the fire the full pressure of 255 lb. was registered, 43 lb. of coal having been used.

We then weighed three 1-cwt, bags of coal and labelled them before loading them on to the vehicle. Making sure that the boiler was at half-glass, the tanks filled and the fire in normal trim, we took the

venick on the weighbridge and adjusted the total weight with load and personnel to 19 tons.

We then immediately started a fuel-consumption run of 60 miles to Llangollen and back along the Holyhead road. Traffic in Shrewsbury and elsewhere involved seven brief halts; one halt was made to poke down the fire, one to turn around at Llangollen, and one when our water supply was exhausted. For fuel-consumption purposes, we completed the 60-miles' run, weighing the remains of our coal on returning to the works.

• Thus we measured water consumption over 45 miles and coal consumption over 60 miles.

During the run, which was along a fairly hilly and somewhat winding road, we found that it was not necessary to maintain the full boiler pressure of 255 lb., and that, for most purposes, a pressure of 200-230 lb. gave ample power. The way the pressure is maintained on long climbs stresses the boiler efficiency.

On the level it is quite easy to maintain speeds showing a margin above the legal limit, and, although a conscientious operator would not do so, the point of mentioning this is to explain that 20 m.p.h. is maintained up moderate gradients.

The safety valve functioned for four short periods before the test run started, and three times during the run. Stoking was maintained regularly, and the fire kept at a constant level right up to our arrival back at the works, Our log shows that the oil pressure remained between 11 lb, and 13 lb. The roads were dry and the air temperature averaged 34 degrees F.

From the particulars given, it will be seen that this was a fair test of both coal and water consumption, and the detailed results, published in the accompanying panel, reveal a satisfactorily economical operation.

On the outward run Chirk Bank, a short gradient of 1 in 12, was approached at 20 m.p.h. with a steam pressure of 245 lb. On this hill the vehicle was brought to rest to change to low gear, and thereafter climbed with power in hand on the middle cut-off position. The other side of the bank on the return journey was ascended in top gear with the late cut-off position, the minimum speed being 9 m.p.h.

Later in the day we made a good climb of Haughmond Hill, near Shrewsbury, which is about half a mile long and has a gradient of 1 in 10 to 1 in 12. Although, on the late cut-off, the speed was reduced to 1 m.p.h., yet the engine pulled steadily and it was not necessary to

engage low gear. The steam pressure at the summit had not dropped from 250 lb. and the -air temperature in the cab registered 62 degrees F.

A steeper hill could not be found in the neighbourhood, but the margin of power on Haughmond Hill satisfied us that it was not necessary to seek a steeper gradient, for the low gear would give a torque increase of no less than 2.72 to 1.

On Haughmond Hill we found that, whilst the steam-operated footbrake would, of course, easily hold the vehicle, the hand-brake alone could not be relied upon to do so. Thereafter, we tested the brakes on a level road and our readings are recorded in the accompanying graph.

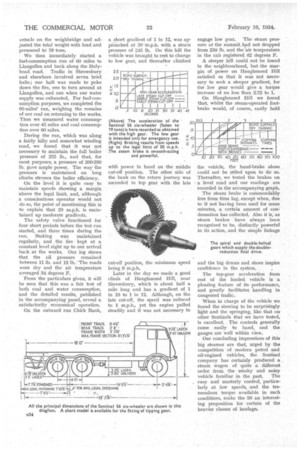

The steam brake is commendably free from time lag, except when, due to it not having been used for some minutes, a certain amount of condensation has collected. Also it is, as steam brakes have always been recognized to be, distinctly powerful in its action, and the simple linkage The spiral and double-helical gears which supply the doublereduction final drive.

and the big drums and shoes inspire confidence in the system.

The top-gear acceleration from rest of the loaded vehicle is a pleasing feature of its performance, and greatly facilitates handling in congested traffic.

When in charge of the vehicle we found the steering to be surprisingly light and the springing, lik-e thnt err other Sentinels that we have tested, is excellent. The controls generally come easily to hand, and the gauges are well within view.

Our concluding impressions of this big steamer are that, urged by the competition of modern petrol and oil-engined vehicles, the Sentinel company has certainly produced a steam wagon of quite a. different order from the smoky and noisy vehicle familiar in the past. The easy and masterly control:particularly at low speeds, and the tremendous torque available in such conditions, make the S6 an interesting proposition for certain of the heavier classes of haulage.