A TRAILING-AXLE RIGID SIX -WHEELER TESTED

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

IN the past two or three years orthodox chassis converted into rigid six-wheelers with drive to only one axle have been employed in Great Britain and elsewhere in large and increasing numbers. They have come into existence because the rigid six-wheeler offers certain advantages of economy and because manufacturers of four-wheelers have been producing chassis having a greater margin of power and strength of transmission components than is necessary for main-road haulage work. The average four-wheeler of the lighter class is built to resist hard usage and is offered as a standard model for all classes of service, town, country, short-distance, long-distance, etc.

It is but natural that transport contractors working regularly on England's excellent main roads should seek to utilize for extra loading that margin of power and strength which they will not have occasion to call upon to resist the stresses of service over rough ground. The rigid six-wheeler with drive to one pair of wheels has, for this work, proved itself satisfactory, and it is particularly suitable when bulky loads are regularly carried.

Some chassis manufacturers have responded to the need by themselves producing) trailing-axle rigid sixwheelers, but much of the pioneering work in regard to the problems of design involved has been undertaken by concerns engtrged in converting four-wheelers into six-wheelers.

The problem includes difficulties of supporting a longer and more B40 heavily loaded body so that the frame may not yield, of minimizing the side drag which is theoretically inseparable from the rigid design, of distributing the load so that the driving wheels will not slip in certain conditions yet the trailing axle will carry its fair share, of allowing for spring flexing without interference with brake connections, etc.

A concern which has had long experience in effecting conversions of this kind is Baico Patents, Ltd., Baico Place, 327-329, High Road, Chiswick, London, W.4. In the past few days we . have submitted a Baico-Ford drop-side lorry to our standard form of road test.

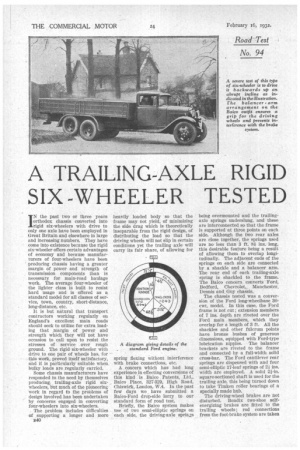

Briefly, the Baico system makes use of two semi-elliptic springs on each side, the driving-axle springs being overmounted and the trailingaxle springs underslung, and these are interconnected so that the frame is supported at three points on each side. Although the two rear axles are close together, the springs used are no less than 3 ft. 8i ins, long, this desirable feature being a result of allowing them to overlap longitudinally. The adjacent ends of the springs on each side are connected by a shackle and a balancer arm. The rear end of each trailing-axle spring is shackled to the frame. The Baico concern converts Ford, Bedford, Chevrolet,_ Manchester, Dennis and Guy chassis.

The chassis tested was a conversion of the Ford long-wheelbase 30cwt. model. In this case, the Ford frame is not cut ; extension members of 7 ins, depth are riveted over the Ford main members, which they overlap for a length of 3 ft. All the shackles and other fulcrum points have bronze bushes of generous dimensions, equipped with Ford-type lubrication nipples. The balancer brackets are riveted to the frame and connected by a full-width solid cross-bar. The Ford cantilever rear springs are dispensed with and four semi-elliptic 17-leaf springs of 2i ins. width are employed. A solid 2i-in. square-sectioned shaft is used for the trailing axle, this being turned down to take Timken roller bearings of a specially made hub. The driving-wheel brakes are not disturbed. Bendix two-shoe selfenergizing brakes are fitted to the trailing wheels ; rod connections from the foot-brake system are taken to a point on each frame member a little before the trailing axle, from which 'point the effort is conveyed to the brake-cam spindles by enclosed flexible cables. Depression of the pedal, therefore, applies brakes on all six wheels, and the Ford hand brake is retained.

There is not space or necessity for us here to describe the Ford chassis. It is of simple and robust layout and has a low-compression engine which develops its maximum power at the remarkably low speed of 2,200 r.p.m. For the Baico conversion the lower rear-axle ratio of 6.6 to 1 is chosen.

We may here explain that Baico Patents, Ltd., reckons upon the Super-BaicoFord carrying a payload of 4 tons, Because the drop-side lorry body fitted to the chassis which we tested weighs less than a Lutontype van body that is frequently chosen, the company added an extra 7 cwt. of pay-load for the purpose of our test. The load carried was sand.

The accompanying acceleration curve gives an idea of the power available with this gross load of 7 tons. The acceleration is ample for ordinary purposes ; the pulling power of the engine at low speeds is nothing less than astonishing and the performance on hills is remarkable. It is possible to climb slight gradients on top gear at 14 m.p.h. Cocks Hill on the Elstree-Barnet road, which is 200 yds. long and has a maximum gradient of 1 in 6, was climbed from rest partly in second but mainly in first gear in 68 secs., giving an average speed of 6 m.p.h. There was ample power in hand. After prolonged hill-climbing tests, the engine was not at all hot.

Without stressing the clutch, a restart in first gear on a gradient of 1 in 6 was effected with ease.

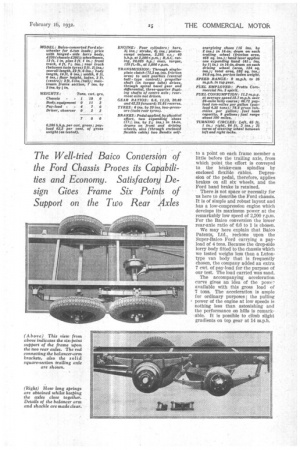

The braking performance is revealed .by an accompanying graph, which shows that the use of foot and hand brakes together gives readings little better than use of the foot brake alone. This is because with both brakes applied the driving wheels are inclined to lock and skid along. The brake action is definitely unaffected by uneven ground and is progressive. Baico Patents, Ltd., offers a Dewandre vacuum cylinder to give increased retardation, and it appears to us that the saving which many hauliers make (16) by omitting the Dewandre servo is not worth while. The foot brake would easily stop and hold the vehicle on 1 in 6; naturally the hand brake alone could scarcely do this. An important point with sixwheeler conversions is the distribution of load. The Baico balancerarm design is good because it ensures transference of part of the trailingaxle load to the driving axle when the trailing wheels are at a higher level. An accompanying illustration shows the vehicle being backed up a steep entrance way. Tests of this kind convinced us that sufficient weight is transferred to ensure the driving wheels securing the necessary grip. Incidentally, such tests also proved the efficacy of the brake linkage, for there was no suggestion of brake binding.

As regards the suspension, the long springs and the provision of six supports for the rear part of the frame are satisfactory features ; apart from the load being well distributed, the elimination of fore-andaft pitching is marked. With rigid six-wheelers pitching can be serious. The outfit rides easily over all ordinary roads and steering is not adversely affected by surface irregularities. The low-pressure tyres are appreciated, but alternative sizes are available for severe duty.

The matter of fuel consumption is

vital, the economy of this type of vehicle being surprising. Our reading of 11.2 miles per gallon was obtained over a short and hilly route, and would undoubtedly be bettered by contractors operating on long-distance haulage, such as between London and Birmingham. We dismantled the carburetter, which was found to have the following setting :—venturi 27-32 in., main jet 20, cap jet 20, compensator 19,

idler 10. The speedometer was tested.

The outfit is easy to control in all conditions, including town traffic.

In conclusion, there is no doubt that, for work on main roads, an outfit of this kind gives an increased load capacity out of proportion to the increase of first cost, maintenance charges or fuel consumption. The unladen weight, and consequently the licence duty, are moderate, the extra garage space is negligible and the average speed is good. Finally, it has to be borne in mind that the Baico concern has converted more than 10,000 Fords and, after, several years of experience, continues to market what must be regarded as a proved product.