For Re-conditioning Cork-insert Clutches

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

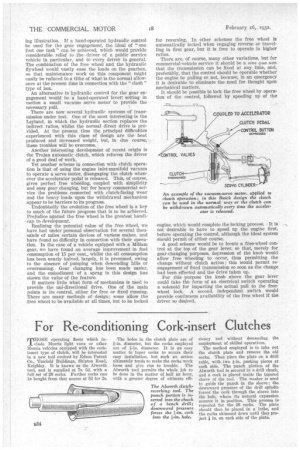

TIIOSE operating fleets which include Morris light vans or other Morris vehicles equipped with the corkinsert type of clutch, will be interested in a new tool evolved by Edson Patent Co., Tanfleld Buildings, Skipton Road, Keighley. It is known as the Alworth tool, and is supplied at 7s. 3d. with a full set of 26 corks. Further corks canbe bought from that source at 52 for 2s.

The holes in the clutch plate are of i-in. diameter, but the corks employed are of i-in. diameter. It is an easy matter to taper corks to secure their easy installation, but such an action ultimately tends to make the corks work loose and give rise to trouble. The Alworth tool permits the whole job to be done in the matter of half an hour, with a greater degree of ultimate etli cieuey and without demanding the employment of skilled operatives.

The method employed is to take out the clutch plate and remove the old corks. Then place the plate on a drill table, with two i-in. packing pieces at each side. The punch pOrtion of the Alworth tool is secured in a drill chuck, and a cork is placed inside the tapered sleeve of the tool. The washer is used to guide the punch in the sleeve; the downward pressure of the drill spindle forces the cork through the sleeve into the hole, where its natural expansion secures it in position. This process isrepeated for the 26 corks. The plate should then be placed in a lathe, and the corks skimmed down until they project in. on each side of the plate.