PETROL TO OIL

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

CONVERSIONS

Some Particulars of the Interesting Methods Employed by the Stobcross Motor Co., Ltd., in Replacing Petrol Engines by Gardner Power Units

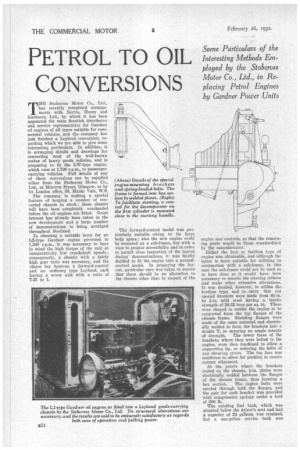

THE Stobcross " Motor Co., Ltd., has recently completed arrangements with Norris, Henty and Gardners, Ltd., by which it has been appointed the main Scottish distributor and service representative for Gardner oil engines of all types suitable for commercial vehicles, and the company has just finished a Leyland conversion, regarding which we are able to give some interesting particulars. In addition, it is arranging details and drawings for converting most of the well-known makes of heavy goods vehicles, and is preparing to fit the LW-type engine, which runs at 1,700 r.p.m., to passengercarrying vehicles. Full details of any of these conversions can be supplied either from the Stobcross Motor Co., Ltd., at Minerva Street, Glasgow, or by its London office, 59, Maida Vale, W.9.

The company is making a special feature of keeping a number of converted chassis in stock ; these chassis will have been completely overhauled before the oil engines are fitted. Great interest has already been taken in the new development and a large number of demonstrations is being arranged throughout Scotland.

In -choosing a suitable lorry for an L2-type Gardner engine governed to 1,300 r.p.m., it was necessary to bear in mind the high torque of the unit at comparatively low crankshaft speeds ; consequently, a chassis with a fairly high gear ratio was necessary, and the .choice lay between a forward-control and an ordinary type Leyland, each having a worm axle with a ratio of 7.25 to 1.

The forward-control model was particularly suitable ()Wing to its large body space ; also the new engine could be mounted on a sub-frame, but with a view to greater accessibility and in order to permit close inspection of the layout during demonstrations, it was finally decided to fit the engine into a normalcontrol modeL In preparing the layout, particular care was taken to ensure that there should be no alteration to the chassis other than in respect of the engine and controls, so that the remaining parts would be those standardized by the manufacturer.

Either the foot or footless type of engine was obtainable, and although the latter is more suitable for utilizing in conjunction with a sub-frame, in this case the sub-frame could not be used as to have done so it would have been necessary to remove the steering column and make other extensive alterations. It was decided, however, to utilize the footless type, and to carry this out special brackets were made from 44-in. • by f-in. mild steel having a tensile strength of 28-32 tons per sq. in. These were shaped to enable the engine to be supported from the top flanges of the chassis frame. Standing flanges were made of the same material and electrically welded to form the brackets into a double T, so ensuring an ample margin of strength. The lower faces of the brackets, where they were bolted to the engine, were then machined to allow a supporting lip, so relieving the bolts t,f any shearing stress. The top face was machined to allow for packing to ensure correct alignment.

At the points where the brackets rested on the chassis, g-in. plates were electrically welded between the flange§ of the chassis frame, thus forming a box section. The engine bolts were carried through both the flanges, and the pair for each bracket was provided with compression springs under a load of 200 lb.

The existing fuel tank, which was situated below the driver's seat and had a capacity of 24 gallons, was retained, but a one-gallon service tank was

bolted to the engine side of the dash, tiros allowing a head of approximately 1 ft. An &IT. 1 amp.-hour Petrolift or pump was mounted on the same side of the dash at such a height that a continual head of fuel could be maintained in the service tank. When this tank is full, the petrol pump is automatically cut off, thus avoiding any possibility of overflow, although there is an overflow pipe leading direct from the pump spray leak to the main tank.

The first filter was bolted immediately, to the off side of the service tank, where it is easily accessible. The existing control levers on the steering column and the foot accelerator were utilized, the hand throttle being coupled up as usual with the accelerator, but the ignition lever was brought into use as a start-and-stop control," being connected to the shut-off valve. This presents the advantage that the driver can operate .this control from the steering

wheel and thus, while coasting, obtain the advantage of a powerful engine brake, because although no fuel is being supplied to the engine a full charge of air is being taken into the cylinders and compressed.

Owing to the low exhaust temperature, a new type of silencer and exhaust pipe were fitted, the silencer being 12 ins. by 8 ins. and having two baffle plates. This silencer was surrounded by an air jacket to prevent too rapid cooling of the exhaust gases, and a short extension pipe was led to the off side of the chassis, immediately at the 'bacit of the driver's seat.

To assist starting, a decompressing control lever was coupled to cylinder number one and an extension was carried to the lower side of the radiator, immediately to the left of the starting .hafidle, so that the cylinder could be used with half or full compression, as desired. The other cylinders, of course,

are all decompressed until the engine is running.

The exhaust temperature was found to be only 450 degrees C. as against approximately 1,000 degrees C. for a petrol engine, and to prevent the engine running too cool, the bore of the watercirculating pipes was reduced ; actually, new copper pipes were fitted, and the fan was dispensed with.

The existing clutch was utilized, but a heavier flywheel was supplied with the engine and machined by the manufacturers to suit this clutch.

Afteethe completion of this first conversion, the engine was started and fired immediately. We have not seen this vehicle, but it is claimed that at all speeds there is a noticeable absence of

vibration. Final tes6 have not yet been completed, but the results so far obtained have •shown-particUlarly.--low fuel consumption, ease of starting and remarkable pulling powers.