CARRYING OUT TYRE REPAIRS.

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

Various Classes of Vulcanizing Equipment for the Garage or User.

THERE is a distinct need for much better _facilities for the repair of pneumatic tyres, not only in respect of their casings but with regard to retreading covers which are sound, except for the fact that their treads are unduly worn. It is obviously useless to go to the expense of retreading a casing which is in such a condition that it will not be able to stand up for any considerable length of time, but where the casing is good the life of the tyre may be increased by anything from 5,000 to 10,000 miles, and, in exceptional cases, for longer distances than these, if the repairs be carried out well.

Extensive repairs to broken casings or fabric cannot satisfactorily be dealt with by the user, as they, normally, require special plant, often to be found only at the works of the manufacturers, but if suitable equipment can be obtained, not only garages, but users who have a large number of vehicles in service can carry out their own retreading With no -great difficulty.

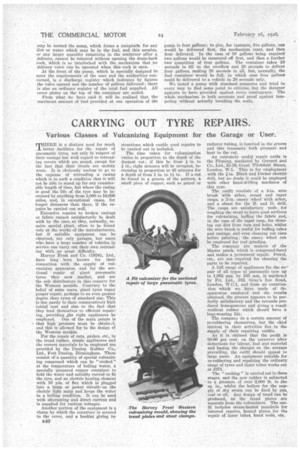

Harvey Frost and Co. (1924), Ltd., have long been known for their connection with the supply of vulcanizing apparatus, and for the sectional repair of giant pneumatic tyres they now market, and are the sole distributors in this country for the Western moulds. Contrary to the .belief of some users, giant' tyres repay • proper repair, perhaps to an even greater degree than tyres of standard size. This is due partly to their comparatively high

• initial cost and also to the fact that they lend themselves to efficient repairing, providing .,,the right appliances be employed. One of the main points is • that high pressure most be obtaitrA, and this is allowed for in the design of the Western moulds. .

For the repair of cuts, gashes, etc., in the tread rubber, simple appliances and the correct materials to be employed are provided by the Dunlop Rubber Co., Ltd., Fort Dunlop, Birmingham. These consist of a quantity of special vulcanizing compound which can be " cooked " at the temperature of boiling water, a specially prepared copper container to hold the water and suitably curved to fit the tyre, and an electric heating element with 10 yds. of flex which is plugged into a lamp or power circuits on the electric light main and keeps the water in a boiling condition. It can be used with alternating and direct current and is supplied for various voltages.

Another portion of the equipment is a clamp by which the container is secured to the cover, and a booklet giving in l340 structions which enable good repairs to be carried out is included.

The time taken for vulcanization varies in proportion to the depth of the deepest cut ; if this be from in. to in., eight minutes will be occupied, increasing in proportion to 45 minutes for a depth of from'l in. to 14 in. If a cut be found in a groove of the pattern, a small piece of copper, such as petrol or radiator tithing, is inserted in the groove and this transmits both pressure and heat to the cut.

An extremely useful repair outfit is the Fleming marketed by Gerrard and Co., Ltd., 15219, Great Titchfield Street, London W.1. This is for employment with the i-in. Black and Decker electric drill, but no doubt it could be employed with other hand-drilling machines of this type.

The outfit consists of a 4-in, wire brush with arbor, round and taper rasps, a 3-in. emery wheel With arbor, and a stand for the B. and D. drill. The rasps are satisfactory tools for roughing the tread to leave good surfaces for vulcanizing, buffing the fabric and, in the ease of the taper rasp, for cleaning out dirt from cuts and holes, whilst the wire brush is useful for buffing tubes and casings, and even cleaning out rims before painting ; the emery wheel can be employed for tool grinding.

The company are makers of the Master patch, which is compound-faced and makes a permanent repair. Petrol, etc., are not required for cleaning the parts to be repaired.

A full range of appliances for the re--pair of all types of pneumatic tyre up to 1,085 mm. by 185 mm. is marketed by Pit, Ltd. 162, Gray's Inn Road, London, W.6.1, and from an examination 'which we have made of thc apparatus employed and the results obtained, the process appears to be perfectly satisfactory and the retreads produced homogeneous and giving a tough resilient rubber which should have a bug-wearing life.

The company do a certain amount of re-rubbering themselves, but the chief interest in their activities lies in the supply of their repairing outfits.

As it is claimed that the profit is 50-60 per cent, on the turnover after deductions for labour, fuel and material and basing the charges on the average prevailing, the outfit should appeal to large users. An equipment suitable for re-rubbering and repairing the ordinary range of tyres and inner tubes works out at f371.

The " cooking " is carried out in three stages, and the new rubber is subjected to a pressure of over 2,000 lb. to he sq. in., whilst the boilers for the supply of dry steam can be fired by gas,. coal or oil. Any design of tread can be Produced, as the tread pieces are separate from the vulcanizers. The outfit includes steam-heated mandrels for internal repairs, heated plates for the

• repair of inner tubes, hand tools, etc.