ACCURACY IN PETROL SUPPLY.

Page 23

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

The First Complete Description of the New Gex Petrol Distributor, Which, Once Accurately Adjusted, Cann& Give Short Measure and is Unaffected by Wear.

TETE PROBLEM of designing a petrol supply pump which will give strictly accurate measurement under all conditions of service, not only when neW, but after prolonged service, and which is, at the same time proof against tampering, is one which has for long •exercised the minds of those concerned in the sup-ply of equipment for the retail distribution of liquid fuel and for the use of large commercial users who wish to keep an accurate cheek on

• ceesuraption.• Recent tests have shown that many of the existing pumps , are by no means accurate, and the only point in their favour

• is that, on the average, they have been shown to give a surplus rather than a deficiency. It is highly probable that this stet?, of affairs will not be allowed to continue for long, as a Bill to amend the law with respect to measuring instruments has been brought forward and may -soon become law, and the officials concerned will be empowered thereby periodically to test measuring apparatus, such as petrol pumps. It is known as the Weights and Measures (Amending) BilL

In connection with petrol supply pumps, we recently visited Messrs. Bywater and Co., 121, Kingsway, London, W.C.2, the sponsors of the Bywater hydraulic system and who have now become the concessionnaires for the (lex petrol distributor, which possesses features so practical and novel that they deserve special mention.

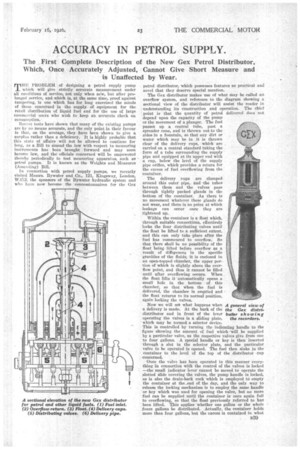

The Gex distributor makes use of what may be called an overflow system, and reference to the diagram showing a sectional view of the distributor will assist •the reader in understanding its construotion and operation. The chief point is that the quantity of petrol delivered does not 'depend upon the capacity of the pump or the movement of a plunger. The fuel passes up a central tube, past a spreader cone, and is thrown out to the sides in a fountain, so that any dirt or water which may be in it is thrown clear of the delivery cups, which are carried on a central standard taking the form of a tube surrounding the supply pipe and equipped at its upper end with a cup, below the level of the supply pipe orifice, which provides .a return for the excess of fuel overflowing from the container.

The delivery cups are clamped around this outer pipe, and 'the tubes between them and the valves pass through tightly packed glands in the bottom of the container. As there is no movement whatever these glands do not wear, and there is no point at which leakage can occur once they are tightened up.

Within the container is a float which, through suitable connections, effectively locks the four distributing valves until the float be lifted to a sufficient extent, and this can only take place after the fuel has commenced to overflow. So that there shall be no possibility of the float being lifted before overflow as a result of diffe,rences in the specific gravities of the fluids, it is enclosed in an open-topped chamber, the upper portion of which is slightly above the overflow point, and thus it cannot be filled until after overflowing occurs. When the float lifts it automatically opens a small hole in the bottom of this chamber, so that when the fuel is delivered, the chamber is emptied and the float returnA to its normal position, again locking the valves.

Now we will sea what happens when a delivery is made. At the back of the distributor and in front of the lever operating the valves is a sliding plate, which may be termed a selector device. This is controlled by turning the indicating handle to the figure showing the amount of fuel which will be supplied by a particular valve, as the respective valves give from one to four gallons. A special handle or key is then inserted through a slot in the selector plate, and the particulnr valve to be operated is opened. The fuel then sinks in the container to the level of the top of the distributor cup concerned.

Once the valve has been operated in this manner everything in connection with the control of the valves is locked —the small indicator lever cannot be moved to operate the slotted slide Covering the valves, the pump handle is locked, as is also the drain-back cock which is employed to empty the container at the_end of the day, and the only way to release the locking mechanism is to employ the same handle or key which was used for opening the valve, but no more fuel can be supplied until the container is once again full to overflowing, so that the float previously referred to bas been lifted. This applies whether one gallon or the whole fours gallons be distributed. Actually, the container holds more than four gallons, but the excess is contained in what A general view of the Gex

distri

buter showing the recorders.

m'ay be termed the sump, which forms a receptacle for any dirt or water whieh may be in the fuel, and this surplus, or any larger quantity remaining in the container after a delivery, cannot be removed without opening the drain-back cock, which is so interlocked with the mechanism that no delivery valve can be operated when this cock is open.

At the front of the pump, which is specially designed to meet the requirements of the user and the authorities concerned, is a discharge register which indicates by figures the valve opened and the number of gallons delivered ; there is also an ordinary register of the total fuel supplied. All cover plates on the top of the container are sealed.

• From what we have said it will be realized that the maximum amount of feel provided at one operation of the

pump is four gallons; to give, for instance, five gallons, one would be delivered first, the mechanism reset, and then four delivered. In the case of 10 gallons being required two gallons would be measured off first, and then a further two quantities of four gallons. The container takes 18 seconds to fill to the overflow and 20 seconds to deliver four gallons, making 38 seconds in all, but, normally, the fuel container would be full, in which ease four gallons could be delivered to a vehicle in 20 seconds only.

We tested a pump with standard measures and tried in every way to find some point to criticise, but the designer appears to have provided against every. contingency. The whole mechanism is both accurate and proof against • tampering without actually breaking the seals.