Gas as an Alternative Fuel

Page 93

Page 94

If you've noticed an error in this article please click here to report it so we can fix it.

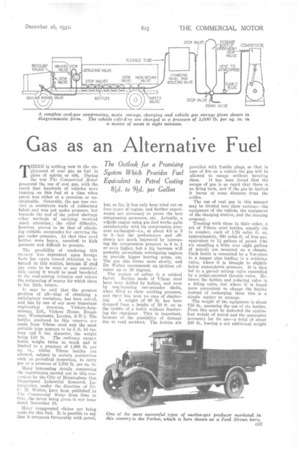

The Outlook for a Promising System Which Provides Fuel Equivalent to Petrol Costing Nd. to 9-id. per Gallon

TIIERE is nothing new in the employment of coal gas as fuel in place of spirits or oils. During the weir The Commercial Motor pioneered the use of coal gas, with the result that hundreds of vehicles were running on this fuel at a time when petrol was either at a premium or unobtainable. Generally, the gas was carried in containers made of rubberized fabric and was not under pressure, but towards the end of the petrol shortage other methods of carrying received much attention; the chief difficulty, bowever, proved to be that of obtaining suitable receptacles for carrying the gas under pressure. At that time steel bottles were heavy, unsuited to high pressure and difficult to procure.

The possibility of rendering this country less dependent upon foreign fuels has again caused attention to be turned to this matter, becauso if coal as were to be used to any considerable extent it would be most beneficial to the coal-mining industry and reduce the outpouring of money for which there is but little return.

it may be said that the greatest problem of all—that of obtaining a satisfactory container, has been solved., and this by one of our most important engineering concerns, Vickers-Armstrong's, Ltd., Vickers House, Broadway, Westminster, London, &W,1. The bottles produced by this concern are made from Vibrac steel and the most suitable type appears to be 5 ft. 10 ins. long and 8 ins, diameter, the weight being 110 lb. The ordinary oxygen bottle weighs twice as much and is limited to a pressure of 1.800 lb. per sq. in., whilst Vibrac bottles are allowed, subject to certain restrictions such as periodical inspection, to carry gas at a pressure of 3,000 lb. per sq. in.

Marty interesting details concerning the experiments carried out in this connection by the City of Birmingham Gas. Department Industrial Research Laboratories, under the direction of Dr. C. M. Walter, have been published in 'I' he Commercial Motor from time to time, the latest being given in our issue dated November 18.

Many exaggerated claims are being made for this fuel. It is possible to say that it compares favourably with petrol,

but, so fur, it has only been tried out on four types of engine, and further experiments am necessary to prove the best compression pressures, etc. Actually, a vehicle engine using gas fuel works quite satisfactorily with its compression pressure unchanged—i.e., at about 4.6 or 5 to 1—but the performance and efficiency are much improved by increasing the eotnpression pressure to 6 to 1 or even higher, but a big increase will probably necessitate redesigning engines to provide bigger bearing areas, etc. The gas also burns more slowly, and Dr. Walter recommends an ignition advance up to 30 degrees.

The matter of safety is a critical factor. Bottles made of Vibrac steel have been drilled by bullets, and even by nap-bursting one-pounder shells, when filled to their working pressure, and there has been no case of shatter ing. A. weight of 80 lb. has been dropped from a height of 30 ft. on to the middle of a bottle without fracturing the container, This is important, because of the possibility of damage due to road accident. The bottles are prov.ided with fusible plugs, so that in case of fire on a vehicle the gas will be allowed to escape without bursting them. It has been found that the escape of gas is so rapid that there is no firing back, and if the gas be ignited it burns at some distance from the orifice.

The use of coal gas in this manner may be divided into three sections—the equipment of the vehicle, the equipment of the charging station, and the running economy.

Treating with these in their order, a set of Vibrac steel bottles, usually six in number, each of 1.76 cubic ft. or, approximately, 360 cubic It. of free gas, equivalent to 11 gallons of petrol (the six equalling a little over eight gallons of petrol) are mounted on a chassis. Each bottle is connected by a Tee-piece to a copper pipe leading to a reducing valve, where it is brought to slightly below atmospheric pressure. It is then led to a gas-air mixing valve controlled by a pedal-operated throttle valve. Between the bottles and reducing valve is a filling valve, but where it is found more convenient to change the bottles instead of recharging them this is a simple matter to arrange.

The weight of the equipment is about 750 lb., assuming the use of six bottles. From this must be deducted the equivalent weight of petrol and the apparatus necessary for its use—a total of about 168 lb., leaving a net additional weight of 582 lb., or just over 5 cwt. The .number of bottles naturally depends upon the size of the vehicle, the space available, and the allowable extra weight which can be carried without excessive reduction of the pay-load capacity.

As regards the equipment of the charging station, this consists of one or more compressors, usually of the four-stage type, working at a final pressure of 5,000 lb. per sq. in., and a set of storage bottles. The gas is charged into the vehicle bottles through a panel with which connection is made by a flexible pipe. In the panel are a reducing valve, which brings the pressure from 5,000 lb. to 3,000 lb., a relief valve and a main-stop valve, there is also a gauge on the low-pressure side. The storage bottles are made in two sizes5 cubic ft. and 23 cubic ft., respectively. One 23-eubie-ft. bottle will charge seven of the standard-size vehicle bottles. It takes five to seven minutes to fill these bottles.

In respect of running economy, about 260 cubic ft. of gas of a calorific value of 500 B.T.U.s per cubic ft. are equivalent to one gallon of petrol. Experiments with a lorry with six bottles, each of 1.76 cubic ft. capacity, show that it runs about CO miles on each charge of gas. • At Birmingham a Morris-Commercial lorry, also with six bottles, runs 100 miles per charge.

A leading gas company has found that gas costing Pd. to 6d. per therm (each therm equivalent to 200 cubic ft. of gas of a calorific value of 500 B.T.U.s per cubic ft.) is equivalent to petrol at Sid. to (lid. per gallon.

In cases where the compression ratio has been increased, it has been found advisable to fit induction-type magnetos, so as to obtain a stronger spark at all speeds.

As regards the running of engines on coal gas, starting and acceleration are improved, the pulling is practically unaffected, but the maximum speed is reduced by about 3 per cent. ; there is no carbon deposit.

There is another form of gas with which experiments have also been carried out for a great many years. We refer to suction gas obtained from portable producers forming permanent fittings on the vehicles and arranged to operate on such fuels as charcoal, anthracite and even corn cobs or wood in small pieces. France has done more towards the development of such producers than any other country, and holds annual trials. The number of makes is steadily diminishing, and whereas in England, at one time, about four types were made, now there is only one the Barker, made by the Parker Producer-Gas Plant Co., 62, Conduit Street, London, W.1.

Producer-gas holds out considerable possibilities for use in overseas countries where petrol is difficult to procure or expensive and where coal gas is not available, It gives extremely economical running, but the plant usually requires a fair amount of attention, and starting it up from cold presents some little difficulty, whilst unless the compression ratio be raised to a considerable degree there is a loss of power amounting to a figure in the neighbourhood of 25 per cent.