CO-ORDINATING SPRING AND TYRE DESIGN.

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

The Members of the Institution of Automobile Engineers Discuss Tyres and Suspension Problems.

!THAT the chassis designer should work in closer

collaboration with the tyre manufacturer was the key-note of a most interesting paper read before the I.A.E. last Tuesday, which was followed by a full discussion of the points raised. The reader of the paper was Mr. A. Healey, who is on the staff of the Dunlop Rubber Co. The president, Dr. Orrnandy, expressed the feelings of all concerned at the end of the meeting, when he stated that the thanks of everyone were due to the author, to the Dunlop Co., and to the development superintendent. Mr. W. H. Paull, for making public so much of the important -research work carried out by the company during the past few years. The paper emphasized the fact that the tyres are in every way a part of the suspension.

system and should not be considered as separate units, particularly in the case of pneumatics. It is with the Sys tem as a whole that one should deal.

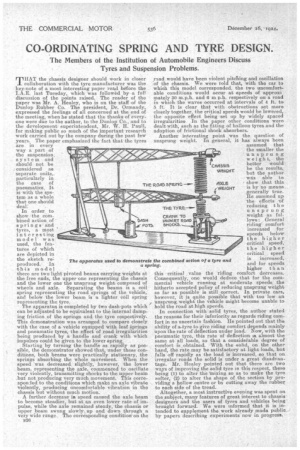

In order to show the com bined action of springs' and tyres, a most * I nteresting model was used, the features of which are depicted in the sketch reproduced. In this model there are two light pivoted beams carrying weights at the free ends, the upper one representing the chassis and the lower one the unsprung weight composed of wheels and axle. Separating the beams is a coil spring representing the road springs of the vehicle, and below the lower beam is a lighter coil spring representing the tyre.

The apparatus is completed by two dash-pots which can be adjusted to be equivalent to the internal damping friction of the springs and the tyre respectively. This demonstration was arranged to compare closely with the case of a vehicle equipped with leaf springs and pneumatic tyres, the effect of road irregularities being produced by a handle and crank with which impulses could be given to the lower spring. Starting by turning the handle as rapidly as possible, the demonstrator showed that, under these conditions, both beams were practically stationary, the springs absorbing the whole movement. When the speed was decreased slightly, however, the lower beam, representing the axle, commenced to oscillate very violently, transmitting shocks to the upper beam .but not producing very much movement. This corresponied to the conditions which make an axle vibrate violently, producing uncomfortable vibration in the chassis but without much motion.

A further decrease i* speed caused the axle beam to become steadier, but at an even lower rate of impulse, while the axle remained steady, the chassis or upper :beam swung slowly, up and down through a very wide range. The corresponding condition on the road would have been violent pitcLing and oscillation of the chassis. We were told that, with the car to which this model corresponded, the two uncomfortable conditions would occur at speeds of approxi rpately 30 m.p.h. and 6 m p.h. respectively on a road in which the waves occurred at intervals of 4 ft. to. 5 ft. It is clear that with obstructions set more closely together, the critical speeds would be lowered, the opposite effect being set up by widely spaced irregularitiesIn the paper other conditions were dealt with, such as the fitting of balloon tyres and the adoption of frictional shock absorbers.

Another interesting point was the question of unsprung weight. In general, it has always been assumed that the smaller the unsprung weight, the better would be the results, but the author wds able to

CHASSIS %imam

AXLE show that this WEIGHT is by no means.

generally true. He summed up the effects of reducing t h e unsprung weight as fol: lows General riding comfort increased for speeds below the higher critical speed, the higher critical speed is increased, and for speeds higher than

this critical value the riding comfort decreases.

Consequently, one would deduce that for the com mercial vehicle running at moderate speeds the hitherto accepted policy of reducing unsprung weight so far as possible is still correct. In private cars,

however, it is quite possible that with too low an „ unsprung weight the vehicle might become unable to

hold the road at high speeds.

In connection with solid tyres, the author stated the reasons for their inferiority as regards riding comfort in no uncertain fashion. He pointed out that the ability of atyre to give riding comfort depends mainly upon the rate of deflection under load. Now, with the pneumatic tyre, this rate of deflection is almost the same at all loads, so that a considerable degree of comfort is _obtained. With the solid, on the other hand, the rate may be satisfactory at light loads, but falls off rapidly as the load is increased, so that on irregular roads the solid is under a great disadvantage. Mr. Healey pointed out that there are two ways of improving the solid tyre m this respect, these being (1) to alter the mixing so as to make the tyre softer, (2) to alter the shape of the section by providing a hollow centre or bv cutting away the rubber to each side of the tread.

Altogether, a most instructive evening was spent on the subject, many features of great interest to chassis designers and the users of tyres and vehicles being brought forward. We were informed that it is intended to supplement the work already made public by papers describing experiments now in progress.