And Not

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

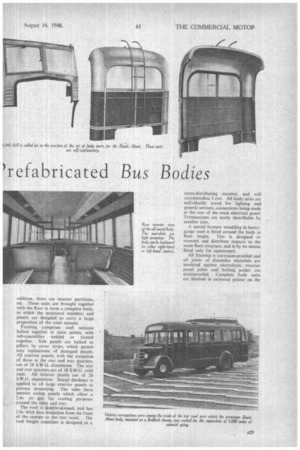

'refabricated Bus Bodies

design of the body, and the matter of stress-distribution has been given great attention. The company built major components for Handley Page Halifax bombers during the war and none of the resultant knowledge has been wasted, either by designers or by engineers.

One of the other outstanding features of the Alnaet public service vehicle, as the complete bus is called, is the interchangeability of components which enables a variety of body types to be built. It is possible to arrange for leftor right-hand drive, with entrances to suit, using an almost identical set of parts. Details, such as pillars and A28 addition, there are interior partitions, etc. These units are brought together with the floor to form a complete body, in which the structural members and panels are designed to carry a large proportion of the total stresses.

Framing comprises steel sections bolted together at main points, with sub-assemblies welded or riveted together. S;de panels are locked to pillars by cover strips, which permit easy replacement of damaged panels. All exterior panels, with the exception of those at the rear and rear quarters, are of 18 S.W.G. aluminium. The rear and rear quarters are of 18 S.W.G. mild steel. All interior panels are of 20 S.W.G. aluminium. Sound deadener is applied to all large exterior panels to prevent drumming. The sides have interior casing panels which allow a 2-in, air gap for cooling purposes around the sides and rear.

The roof is double-skinned, and has 2-in, thick heat insulation from the front of the canopy to the rear waist. The roof freight container is designed as a stress-distributing member, and will accommodate 5 cwt. All body units art: individually wired for lighting and general services, connections being made at the rear of the main electrical panel. Terminations are easily identifiable by number tabs.

A special bumper moulding in heavygauge steel is tilted around the body at floor height. This is designed to transmit and distribute impacts to the main floor structure, and is by no means fitted only for appearance.

All framing is corrosion-proofed and all joints of dissimilar materials are insulated against electrolysis; exterior panel joints and bolting points are waterproofed. Complete body units arc finished in universal primer on the outside and crinkle finish on the inside, with anti-nicotine white-enamelled roofs.

There are interchangeable full-depth partitions behind the driver and between first and second-class compartments, and these give additional rigidity to the body. Various types of window may be fitted, according to local requirements, but all pan units are interchangeable. Ventilation is by six roof-quarter extractors, with large interior grilles, and additional inlets above side windows and under each side of the front canopy.

Optional Seating Plans

Various types of seating layout may be provided to suit operators' requirements, but the prototype is fitted for 28 passengers—eight first-class and 20 second-class. Second-class seats are of slatted all-metal construction, whilst in the first-class compartment they have upholstered cushions and squabs. Frames are of tubular steel. On this vehicle there are both front and rear doors, but the rear one may be replaced by a rear central emergency exit.

There are 10 interior lights in the roof quarters, with semi-flush opal plastic shades. The complete electrical installation is ready for connection to the existing fuse box on the chassis. Destination indicators are built into the front canopy and are controllable from the driver's position. The battery mounting is on the floor unit, with special lead arrangements.

For packing, the body breaks down into the following units:—Floor unit, off side, near side (with doors), rear dome, front windscreen unit, roof unit, seating, partitions and stanchions, chassis-mounting brackets, etc., sparewheel carrier, sundries including service manual, spares schedule, assembly instructions, and special tools.

The rear wings are full-domed in 18 s.w.g. mild steel, whilst the front wings are as supplied on the Bedford chassis.