Gas Cylinders for Commercial Motors.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

The Latest Contribution to the Metal Container Problem.

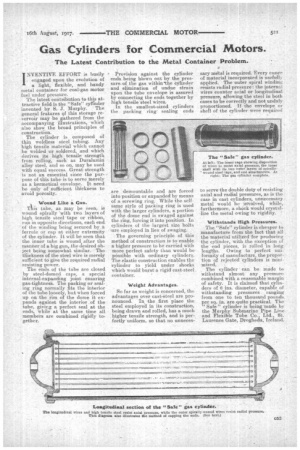

I. NVENTIVE EFFORT is busily engaged upon the evolution of a light, flexible, and handy metal container -for coal-gas motor fuel imdef pressure. The latest contaibution ta this attractive field is the "Safe" cylinder invented by S. J. Murphy. The general features 9f this storage reservoir may be gathered from the accompanying illustrations, which also show the broad principles of

construction. .

The cylinder is composed of thin weldless .. steel tubing. Any high tensile material which cannot be welded or soldered, and which derives its high tensile strength from rolling, such as Duraluinin alloy steel, and so on, may be used with equal success. Great strength is not an essential since the purpose of this tube is to serve merely as a hermetical envelope.. It need be only of • sufficient thickness to avoid porosity.

Wound Like a Gun.

This tube. as may be seen, is wound spirally 'with two layers of high tensile steel. tape or ribbon, . run in opposite directions, each end. of the winding being secured by ferrule or cap at either extremity of the cylinder. It will be seen that the inner tube is wound after the manner of a big gun,,the desired object being somewhat similar. The thickness of the steel wire is merely sufficient to give the required radial resisting power.

The ends of the tube are closed by steel-domed caps, a special internal-expanding joint ensuring gas-tightness. The packing or sealmg ring normally fits the interior of the tube loosely, but when forced up on the rim of the dome it ex. pands against the interior 'of the tube, giving a perfect seal at the ends, while at the same time all members are combined rigidly together.

Provision against the cylinder ends being blown out by the pressure of the gas within-the cylinder and elimination of undue strain upon the tube envelope is assured by connecting the ends together by high tensile steel wires.

In the smallest-sized cylinders the packing ringsealing ends are demountable and are forced into position or expanded by means of a screwing ring. While the selfsame style of Packing ring is used with the larger cylinders, a portion of the dome end is swaged against the ring, forcing it into position. In cylinders of the largest size bolts 'are employed in lieu of swaging.

The governing principle of this method of construction is to enable a higher pressure to be carried with more perfect safety than would be possible with ordinary cylinders. The elastic construction enables the cylinder to yield under shocks which would burst a rigid cast-steel , container.

Weight Advantages.

So far as weight is concerned, the advantages over cast-steel are pronounced. In the first place the steel employed in its construction, beinc, drawn and rolled, has a much higher tensile strength, and is perfectly uniform, so that no unneces

sary metal is required. Every ounce of material incorporated is usefully applied. The outerspiral winding resists radial pressure : the internal wires counter axial or longitudinal pressure, allowing the steel in both cases to be correctly and not unduly proportioned. If the envelope or . shell of the cylinder were required

to serve the double duty of resisting axial and radial pressures, as is the case in cast cylinders, unnecessary metal would be involved, while, furthermore, a shtick would crystallize the metal owing to rigidity.

Withstands High Pressures.

The "Safe" cylinder is cheaper to manufacture from the fact that all the material utilized for producing the cylinder, with the exception of the end pieces, is rolled in long lengths. Owing to perfect mnformity of manufacture, the proportion of rejected Cylinders is minimized. ,

The cylinder can be made to withstand almost any pressure combined with a reasonable margin of safety. It is claimed that cylinders of 6 ins, diameter, capable of withstanding pressures ranging from one to ten thousand pounds, per sq. in. are quite practical. The "Safe" cylinder is being made by the Murphy Submarine Pipe Lille and Flexible Tube Co.,' Ltd., St. Laurence Gate, Drogheda, Ireland.