KE A E! ) , 0 1 , 1G

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

PROFILE

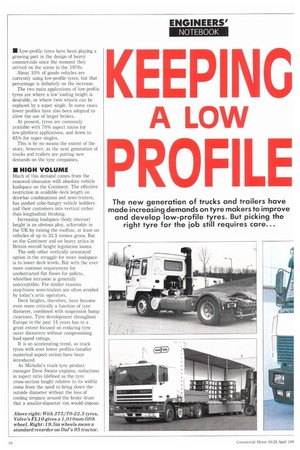

The new generation of trucks and trailers have made increasing demands on tyre makers to improve and develop low-profile tyres. But picking the right tyre for the job still requires care...

• Low-profile tyres have been playing a growing part in the design of heavy commercials since the moment they arrived on the scene in the 1970s.

About 10% of goods vehicles are currently using low-profile tyres, but that percentage is definitely on the increase.

The two main applications of low-profile tyres are where a low loading height is desirable, or where twin wheels can be replaced by a super single. In some cases lower profiles have also been adopted to allow the use of larger brakes.

At present, tyres are commonly available with 70% aspect ratios for low-platform applications, and down to 65% for super singles.

This is by no means the extent of the story, however, as the next generation of trucks and trailers are putting new demands on the tyre companies.

• HIGH VOLUME

Much of this demand comes from the renewed obsession with absolute vehicle loadspace on the Continent. The effective restriction in available deck length on drawbar combinations and semi-trailers, has pushed cube-hungry vehicle builders and their customers into vertical rather than longitudinal thinking.

Increasing loadspace (body interior) height is an obvious ploy, achievable in the UK by raising the roofline, at least on vehicles of up to 32.5 tonnes gross. But on the Continent and on heavy artics in Britain overall height legislation looms.

The only other vertically orientated option in the struggle for more loadspace is to lower deck levels. But with the ever more common requirement for unobstructed flat floors for pallets, wheelbox intrusion is generally unacceptable. For similar reasons step-frame semi-trailers are often avoided by today's artic operators.

Deck heights, therefore, have become even more critically a function of tyre diameter, combined with suspension bump clearance. Tyre development throughout Europe in the past 15 years has to a great extent focused on reducing tyre outer diameters without compromising load-speed ratings.

It is an accelerating trend, as truck tyres with ever lower profiles (smaller numerical aspect ratios) have been introduced.

As Michelin's truck tyre product manager Dave Swann explains, reductions in aspect ratio (defined as the tyre cross-section height relative to its width) come from the need to bring down the outside diameter without the loss of cooling airspace around the brake drum that a smaller-diameter rim would impose.

• LOW HEIGHT TRACTORS

Daf Trucks mould-breaking 19.5in-wheeled maximum-weight tractive unit exhibited at the Amsterdam truck show in February, with its fifth-wheel plate only 950mm above ground level, illustrates the brake heat dissipation problem.

The radial clearance between the drums and the 19.5in wheel rims enclosing them is reduced to such an extent that Daf is making an expensive Voith hydraulic retarder mandatory equipment on the chassis.

It has the effect of protecting the foundation brakes against the heat-induced ravages of fade and accelerated lining wear.

Substituting 19.5 for 22.5in tyres in any case brings down fifth-wheel height by only 70mm, points out Leyland Daf, which has chosen not to import the 19.5in model for the time being — it is bringing in the 22.5in model (which uses "standard" 275/70-22.5 tyres).

In any case, British operators demanding absolute maximum cube tend to run sub-32.5 tonne vehicles, where overall height can be eased upwards. Even on heavy artics, the British 4.2m height limit is 0.2m more than the Continental limit.

Through its radical downsizing in tyre/wheel diameter, from 22,5 to 19.5in, as a means of lowering the chassis, Daf has avoided the need for an ultra-low tyre aspect ratio. The covers are an established industry size 305/70-19.5.

Other height-conscious tractor builders are adopting a more cautious approach, tolerating 30 or 40mm higher couplings in return for 22.5in wheels and hence "standard" brake rim cooling clearances.

But the caution displayed by truck manufacturers such as MAN, Volvo, Nem and Scania is arguably outweighed by the switch to a new very low-profile (60%) tyre size.

The 285/60-22.5 covers, from Continental Tyres, have yet to go into full production, but strong interest in the chassis height saving possibilities of the latest 22.5in tyre is inevitable, on heavy rigids as well as on tractive units.

• LOAD RATING

Unfortunately, the 285/60-22.5 tyre restricts front axle capacity to just 6.3 tonnes — insufficient for today's 17-ton or tomorrow's 18-tonne GVW 4x2 rigid distribution vehicles. However, wider an therefore heavier-capacity 60%

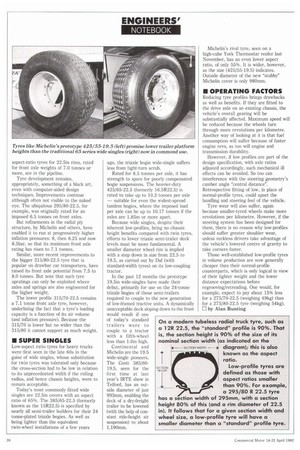

aspect-ratio tyres for 22.5in rims, rated for front axle weights of 7.0 tonnes or more, are in the pipeline.

Tyre development remains, appropriately, something of a black art, even with computer-aided design techniques. Improvements continue although often not visible to the naked eye. The ubiquitous 295/80-22.5, for example, was originally rated for an imposed 6.5 tonnes on front axles.

But refinements in the radial ply structure, by Michelin and others, have enabled it to run at progressively higher inflation pressures: 8, then 8.25 and now 8.5bar, so that its maximum front axle rating has risen to 7.1 tonnes.

Similar, more recent improvements to the bigger 315/80-22.5 tyre that is popular on drawbar car transporters, have raised its front axle potential from 7.5 to 8.0 tonnes. But note that such tyre upratings can only be exploited where axles and springs are also engineered for the higher weight.

The lower profile 315/70-22.5 remains a 7.1 tonne front axle tyre, however, underlining the fact that a tyre's loading capacity is a function of its air volume (and inflation pressure). Because the 315/70 is lower but no wider than the 315/80 it cannot support as much weight.

• SUPER SINGLES

Low-aspect ratio tyres for heavy trucks were first seen in the late 60s in the guise of wide singles, whose substitution for twin tyres was tolerated only because the cross-section had to be low in relation to its unprecedented width if the rolling radius, and hence chassis heights, were to remain acceptable.

Today's most commonly fitted wide singles are 22.5in covers with an aspect ratio of 65%. The 385/65-22.5 (formerly known as the 15R22.5) is specified by nearly all semi-trailer builders for their 24 tonne-plated triaxle bogies. As well as being lighter than the equivalent twin-wheel installations of a few years ago, the triaxle bogie wide-single suffers less from tight-turn scrub.

Rated for 8.5 tonnes per axle, it has strength to spare for poorly compensated bogie suspensions. The heavier-duty 425/65-22.5 (formerly 16.5R22.5) is rated to take up to 10.3 tonnes per axle — suitable for even the widest-spread tandem bogies, where the imposed load per axle can be up to 10.17 tonnes if the axles are 1.85m or more apart.

Because wide singles, despite their inherent low-profiles, bring no chassis height benefits compared with twin tyres, efforts to lower triaxle semi-trailer deck levels must be more fundamental A smaller diameter wheel rim is implied with a step down in size from 22.5 to 19.5, as carried out by Daf (with standard-width tyres) on its low-coupling tractor.

In the past 12 months the prototype 19.5in wide-singles have made their debut, primarily for use on the 24-tonne triaxle bogies of those semi-trailers required to couple to the new generation of low-framed tractive units. A dynamically unacceptable deck sloping down to the front would result if one of today's standard trailers were to couple to a tractor with a fifth-wheel less than 1,0m high.

Continental and Michelin are the 19.5 wide-single pioneers. The Conti 385/6019.5, seen for the first time at last year's IRTE show in Telford, has an outside diameter of just 993mm, enabling the deck of a dry-freight trailer to be lowered (with the help of constant ride-height air suspension) to about 1,190mm. Michelin's rival tyre, seen on a high-cube York Thermostar reefer last November, has an even lower aspect ratio, of only 55%. It is wider, however, as the size (425/55-19.5) indicates. Outside diameter of the new "stubby" Michelin cover is only 980mm.

• OPERATING FACTORS

Reducing tyre profiles brings drawbacks as well as benefits. If they are fitted to the drive axle on an existing chassis, the vehicle's overall gearing will be substantially affected. Maximum speed will be reduced because the wheels turn through more revolutions per kilometre. Another way of looking at it is that fuel consumption will suffer because of faster engine revs, as too will engine and transmission durability.

However, if low profiles are part of the design specification, with axle ratios adjusted accordingly, such mechanical ill effects can be avoided. So too can interference with the steering geometry's camber angle "central distance". Retrospective fitting of low, in place of normal-profile tyres, could upset the handling and steering feel of the vehicle.

Tyre wear will also suffer, again because smaller-tyred wheels make more revolutions per kilometre. However, if the steering system has been designed for them, there is no reason why low-profiles should suffer greater shoulder wear, unless reckless drivers take advantage of the vehicle's lowered centre of gravity to take corners faster.

Those well-established low-profile tyres in volume production are now generally cheaper than their normal-profile counterparts, which is only logical in view of their lighter weight and the lower distance expectations before regrooving/retreading. One would, for example, expect to pay about 15% less for a 275/70-22.5 (weighing 49kg) than for a 275/80-22.5 tyre (weighing 54kg). Eby Alan Bunting