Belt discharge bulkers will carry bricks

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

• An unusual type of dual-purpose semi-trailer has been developed by Barham Bodies Ltd of Northampton. It is a belt-discharge bulk carrier with fold-flat sides enabling it to be used as a straight-forward platform trailer for carrying general-purpose loads. Claimed advantages of this concept over a conventional fold-flat or dropside tipper of this size are that it gives the operator an increase in payload of over a ton and a reduction in platform loading height of well over a foot.

To recess the belt into a channel below the level of the main deck, Barham's engineers have worked in conjunction with the. truck equipment division of the York Trailer Co Ltd in adapting York's coil-carrying semi-trailer design. The width of the main frame was increased from 41 to 45in. so that the 90deg vee-channel could accommodate the 18in.-wide belt, 6in. below the main platform.

York's wide-track tandem-axle running gear is used, with single-leaf spring suspension and Goodyear Super Single 18-19.5 traction road lug tyres; but the unit can be supplied on twin tyres. In common with the normal York coil carrier models, the outer edges of the deck are braced to the bottom of the 18in.-deep main-frame I-beams.

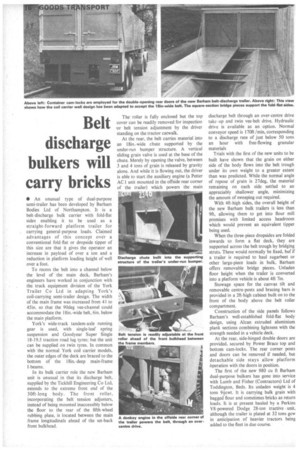

In its bulk carrier role the new Barham unit is unusual . in that its discharge belt, supplied by the Tickhill Engineering Co Ltd, extends to the extreme front end of the 30ft-long body. The front roller, incorporating the belt tension adjusters, instead of being mounted inaccessibly below the floor to the rear of the fifth-wheel rubbing plate, is located between the main frame longitudinals ahead of the set-back front bulkhead. The roller is fully enclosed but the top cover can be readily removed for inspection or belt tension adjustment by the driver standing on the tractor catwalk.

At the rear, the belt carries material into an 18in.-wide chute supported by the under-run bumper structure. A vertical sliding grain valve is used at the base of the chute. Merely by opening the valve, between 3 and 4 tons of grain is released by gravity alone. And while it is flowing out, the driver is able to start.the auxiliary engine (a Petter AC1 unit mounted in the offside rear corner of the trailer) which powers the main discharge belt through an over-centre drive take-up and twin vee-belt drive. Hydraulic drive is available as an option. Normal conveyor speed is 170ft /min, corresponding to a discharge rate of just below 50 tons an hour with free-flowing granular materials Trials with the first of the new units to be built have shown that the grain on either side of the body flows into the belt trough under its own weight to a greater extent than was predicted. While the normal angle of repose of grain is 27deg, the material remaining on each side settled to an appreciably shallower angle, minimizing the amount of sweeping out required.

With 4ft-high sides, the overall height of the new Barham bulk trailers is less than 9ft, allowing them to get into flour mill premises with limited access headroom which would prevent an equivalent tipper being used.

When the three-piece dropsides are folded inwards to form a flat deck, they are supported across the belt trough by bridging struts. These would normally be fixed, but if a trailer is required to haul sugarbeet or other large-piece loads in bulk, Barham offers removable bridge pieces. Unladen floor height when the trailer is converted into a platform vehicle is about 4ft 7in.

Stowage space for the canvas tilt and removable centre-posts and bracing bars is provided in a 2ft-high cabinet built on to the front of the body above the belt roller compartment.

Construction of the side panels follows Barham's well-established fold-flat body design, using Akan extruded aluminium plank sections combining lightness with the strength needed in a vehicle deck.

At the rear, side-hinged double doors are provided, secured by Power Brace top and bottom cam-locks. The rear corner posts and doors can be removed if needed, but detachable side stays allow platform Operation with the doors in position.

The first of the new 980 cu ft Barham dual-purpose bulkers has gone into service with Lumb and Fisher (Contractors) Ltd of Toddington, Beds. Its unladen weight is 4 tons 9i-cwt. It is carrying bulk grain with bagged flour and sometimes bricks as return loads. It is at present hauled by a Perkins V8-powered Dodge 28-ton tractive unit, although the trailer is plated at 32 tons gcw in anticipation of heavier tractors being added to the fleet in due course.