Bedford Er

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

Ps " H av y "

Market with 31

L.p.h. 7-tonners ARANGE of 7-toriners and a passenger chassis which, apart from changing the driving position from the right to the left, are suitable withbut modification for home or overseas use, have been introduced by Vauxhall Motors, Ltd., Luton, to supplement existing Bedford vehicles. These new cabover-engine models abound with innovations. The principal chassis features are a 110 b.h.p. power unit, four-speed synchromesh gearbox, hypoid drive to the rear axle and a hydro-mechanical braking system. Equipped with standard tyres and body, the drop. sided version weighs 1 cwt. under 3 tons in its taxation condition and the tipper is 1 cwt. under the limit for a 30 m.p.h. vehicle.

Although no drastic cut in weight is apparent in any component, a big saving has been made in designing the chassis frame to dispense with the need for body runners. A cab-cooling and ventilation system has added to the unladen weight, but it has been incorporated as one of many aids to driving efficiency and comfort.

Slip-fit Liners The 4.92-litre six-cylindered overhead-valve petrol engine is outwardly similar to the well-established units used in the 5-tonners, but it includes full-length dry cylinder liners in addition to a seven-bearing crankshaft with induction-hardened journals and steel-shell copper-lead-lined pre-finished bearings for the mains and big-ends Positively controlled crankcase ventilation, incorporating an A.C. control valve in the inlet manifold, is retained in the new unit, which has short exhaust passages through the water jacket to reduce the heat transmitted to the cooling water.

Bore and stroke dimensions are 31 ins. by 4.1 ins., and the maximum output is 110 b.h.p. at 3,200 r.p.m. and a torque of 234 lb.-ft. is developed at 1,200 r.p.m. Complete with accessories •and silencer, the power available is 94 b.h.p. at 3,000 r.p.m., the torque under similar conditions being 220 lb.-ft. at 1,200 r.p.m. A harmonic damper is attached to the front of the crankshaft in conjunction with the fan-drive pulley. The lubrication system includes an A.C. by-pass detachableelement filter, and the filler, attached to the valve-rocker cover, is combined with the crankcase-ventilation oil bath air cleaner. • The power unit, 12-in, diameter clutch and gearbox, are carried by a conventional three-point system,. there being a single pad at the front and, at the rear, trunnions attached to the outer ends of the crankcase rear plate and the main-frame side and bottom flanges. All the mounting assemblies are rubber insulated.

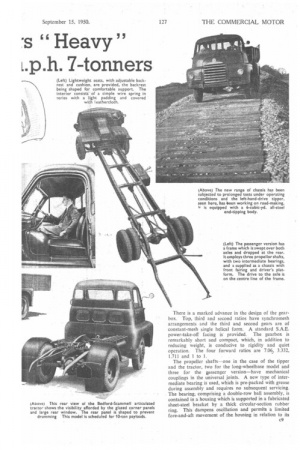

c.B There is a marked advance in the design of the gearbox. Top, third and second ratios have synchromesh arrangements and the third and second gears are of constant-mesh single helical form. A standard S.A.E. power-take-off facing is provided. The gearbox is remarkably short and compact, which, in addition to reducing weight, is conducive to rigidity and quiet operation. The four forward ratios are 7.06, 3332, 1.711 and 1 to 1.

The propeller shafts—one in the case of the tipper and the tractor, two for the long-wheelbase model and three for the Rassenger version—have mechanical couplings in the universal joints. A new type of intermediate bearing is used, which is pre-packed with grease during assembly and requires no subsequent servicing. The bearing, comprising a double-row ball assembly, is contained in a housing which is supported in a fabricated sheet-steel bracket by a thick circular-section rubber ring. This dampens oscillation and permits a limited fore-and-aft movement of the housing in relation to its

bracket. Rotation of the housing within the rubber ring is prevented by a rat-trap spring arrangement.

An orthodox rear axle of Bedford pattern is used, the housing being a composite assembly of a malleable castiron centre section with pressed-in tubular extensions. The brake-anchor plates, shock-absorber brackets and spring pads are welded to the tube and the centre of the differential case is on the chassis centre line. The axle is a fully floating unit and hypoid gear is available, with ratios of 6.8 and 5.833 to I.

In the hydro-mechanical braking system, the shoes are operated hydraulically at the front and mechanically at the rear The Lockheed brake master cylinder incorporates two pistons in tandem, one part of the system being connected direct to the front axle, whilst the other actuates the rear-axle shoes through a relay of rods and levers. This tandem piston arrangement ensures that the rear brakes remain in operation should there be a failure in the front hydraulic system, and vice versa.

The rear brakes are operated by transverse rods coupled to bisector-expander rollers and a semi-floating Jperating lever mounted on the axle case. This lever is linked to the relay from the hydraulic system and by

cables to the hand-brake lever. Shoe actuation is by the normal leading-shoe arrangement used in all Bedford vehicles. Clayton Dewandre vacuum-servo units are provided on all the new models except the tractor, which is specially equipped for semi-trailer operation.

A few pounds dead weight has been saved in the steering gear without affecting its efficiency or strength. The steering box is bolted rigidly to the frame and the column is connected to the box through a fabric universal joint. There is a short tube at the top of the column which is supported by a rubber-bushed bracket attached to the instrument panel. A further weight-saving measure is the use of an H-section drop-forging in place of the conventional tubular push-pull rod.

A pressurized radiator of large frontal area is used. The fan operates in a shroud, and canvas scoops are provided between the grille and core. The radiator is constructed to operate with an internal pressure of 21 lb. to 31 lb. per sq. in., which would raise the boiling point of the cooling water to 221-224 degrees F.

Because the chassis frame is relatively high in relation to its wheels and components, the engine cover occupies comparatively little space in the cab, which can be equipped to accommodate a crew of three. The intrusion of the cover prevents the use of a full-width seat, and for home service, where weight is important, there is a single seat for the driver and another for the Cl 0 mate. The cab is of all-steel construction, the main structure being welded and fitted with replaceable exterior panels. The scuttle and dash assembly, together with the steel instrument panel, is welded to the main structure and forms additional reinforcement.

The engine cowl is of double-skin construction, with an air gap between the inner and outer panels. An air flow is maintained through the interior area by suction from the fan and prevents the engine heat from penetrating through to the cab. An air inlet for the engine cowl is arranged behind a louvre at the bottom of the cab front panel. A divided windscreen is fitted in which the driver's half is hinged at the top and may be opened to the horizontal position. The opposite side is fixed, but an additional opening screen is available in place of the fixed unit as an optional extra.

Enclosed Cab Step Further ventilation is available from the door windows, which are of the self-balancing drop pattern operated by a grip attached to the edge of the glass. The doors, carried on the front pillar by self-aligning hinges, have a skirt at their base which encloses a step

on the top of the wing. Visibility is good in all directions because of the provision of corner lights and a large centre rear window Safety glass is used as standard for all cab glazing.

The hardwood standard body is 16 ft. long and has a flat floor with drop sides and tailboard. Sides, tailboard and posts can be removed to leave a platform body 7 ft. 5 ins. wide. A 6-cubic-yd. welded-steel body is available for the end-tipper, which has a telescopic ram at the front. The combined oil-tank reservoir and control unit is carried inside the cab under a seat.

The articulated machine, which is nominally rated for a 10-ton payload for home purposes and 9 tons overseas, has a wheelbase of 7 ft. 2 ins. The wheelbase of the end-tipper is 9 ft. 8 ins., and of the drop-sided lorry 13 ft.

For 33-seater Body The passenger chassis, designed for a 33-seater coach body, is 27 ft. 41 ins, long and has a wheelbase of 17 ft. 2 ins. It is arranged with a front overhang of 3 ft. 01 in., and an extension of 7 ft. 11 ins, behind the rear axle. Its frame is swept over both axles and dropped at the rear. At the centre it is 2 ft. 4 ins. above ground level when fully loaded. The width over the rear wheels is 7 ft. 3-176ins. The passenger version has the new frontal styling employed in the goods models and is available with front fairing and driver's platform, but minus windscreens, doors and cab.

Tyre. equipment of 8.25 by 20 ins., 35 by 7+ ins, is standard for home use on the tipper and drop-side truck. The tractor has 7.50 by 20-in., 34 by 7-in. equipment, and the passenger chassis 8.25 by 20. For overseas a tyre of 9.00 by 20 ins, is available on the tipper and long-wheelbase truck.

At the outset, the new Bedford models will be available only for the export market. Features incorporated in the overseas types include the alternative tyre equipment, an opening windscreen on the mate's side of the cab and an Eaton two-speed rear axle.

The new range, to be known as the S type, is equipped with 12-volt lighting and starting equipment, On the goods models the dynamo output is regulated by a compensated-voltage-control system, the combined cutout controller and fuse box containing two auxiliarycircuit fuses being conveniently mounted in the cab. The passenger chassis has a current-voltage system in which the combined cut-out controller and dynamo field fuse box is located alongside the driver's seat.