Compact Engine Layout in New Guy Chassis

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THE new Guy underfloor-engined single decker series, briefly described in "The Commercial Motor" on September 1, is constructed with most of the component parts employed in the existing range of Arab chassis, so that the two types may be operated together without any marked increase in the number of stores items.

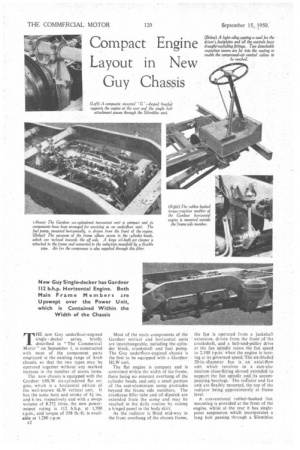

The new chassis is equipped with the Gardner 6HLW six-cylindered flat engine, which is a horizontal edition of the well-known 6LW vertical unit. It has the same bore and stroke of 4.1 ins. and 6 ins, respectively and with a swept volume of 8.372 litres, the new poweroutput rating is 112 b.h.p. at 1,700 r.p.m., and torque of 358 lb.-ft. is available at 1.280 r.p.m.

c2 Most of the main components of the Gardner vertical and horizontal units are interchangeable, including the cylinder block, crankshaft and fuel pump. The Guy underfloor-engined chassis is the first to be equipped with a Gardner HLW unit.

The flat engine is compact and is contained within the width of the frame, there being no external overhang of the cylinder heads, and only a small portion of tha cast-aluminium sump protrudes beyond the frame side members. The crankcase filler tube and oil dipstick are extended from the sump and may be reached in the daily routine by raising a hinged panel in the body skirt.

As the radiator is fitted mid-way in the front overhang of the chassis frame, the fan is operated from a jackshaft extension. driven from the front of the crankshaft, and a belt-and-pulley drive at the fan spindle raises the fan speed to 2,100 r.p.m. when the engine is turning at its governed speed. The six-bladed 20-in.-diameter fan is an axial-flow unit which revolves in a cast-aluminium close-fitting shroud extended to support the fan spindle and its accompanying bearings. The radiator and fan unit are flexibly mounted, the top of the radiator being approximately at frame level.

A conventional rubber-bushed link mounting is provided at the front of the engine, whilst at the rear it has singlepoint suspension which incorporates a long bolt passing through a Silentbloc

pad and the flywheel housing. As the engine has a limited movement on its mountings, with a rubber-bushed torque restrainer attached outside the frame, the oil-bath air cleaner is rigidly attached to the frame and has a flexible pipe connection to the induction manifold. This cleaner also filters air for the compressor..

The two-cylindered air compressor is. secured inside the frame behind the engine and is drivenby belt and pulley from the inter-propeller shaft connecting the fluid coupling to the gearbox. At present Guy flat-engine chassis are being produced with a six,-eylindered power unit, fluid coupling, air-pressure brakes and preselective gearbox.

Subsequent models will be available with larger or smaller engines, and single-dry-plate clutches and constantmesh gearboxes will be offered for those who prefer them. A triple-servo vacuum braking system will also be included as an alternative to the compressed air system. Where vacuum braking is specified, the gear-engagement pedal will be linked mechanically to the bus-bar in the gearbox. In the Guy chassis to be shown a! Earls Court, the preselect lye gearbox is operated by compressed air, the normal bus-bar spring being replaced by a cylinder and piston.

Compressed-air operation of the gearbox, in conjunction with the fluid coupling, reduces the number of mechanical connections between the driver's controls and the transmission. There is a rod and relay lever linkage between the change-speed lever and gearbox operating quadrant, but this is neatly arranged by using a crossshaft at the front of the frame and a linkage inside the frame side member.

Straight Transmission Line

The crankshaft centre line falls close to the chassis side member, and to maintain a straight transmission line the gearbox and overhead worm drive to the rear axle are both offset towards the near side. The axle is fully floating, the drive ratios available being 4.8 and 5.6 to I.

It is of a similar type to that used in the Guy double-decker, but is inverted. and the brake components ffe arranged .

accordingly. The rear. --springs are underslung, a feature of the chassis being that the spring brackets are corn-.. posite units and all eight hanger brackets are interchangeable.

These flat-engined chassis are available with rightor left-hand drive, and in wheelbase lengths of 16 ft. 4 ins. and 17 ft. 6 ins, for body lengths of 30 ft. and up to 35 ft. respectively. The 30-ft. home model has a chassis front overhang of 5 ft. 41 ins., whilst the rear overhang is 7 ft. 7i ins. The chassis are available as 7-ft. 6-in. or 8-ft.-wide models.

Tyre equipment for the 7-ft. 6-in.wide chassis is 9.00 by 20 ins., whilst the wider models may have 10.00 or 11.00 by 20-in. tyres. Home models are designed for a bus body seating 44 passengers, or a 40-seater coach body.

A representative chassis of the underfloor engined range will be exhibited on the Guy stand at Earls Court, whilst a secoiid model, with a Guy body made at Wolverhampton under Park Royal licence, will be seen.