The Latest

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

FOWLER OIL ENGINE

Novel Design of Piston with a Cavity to Provide a Chamber to Prolong the Combustion Period

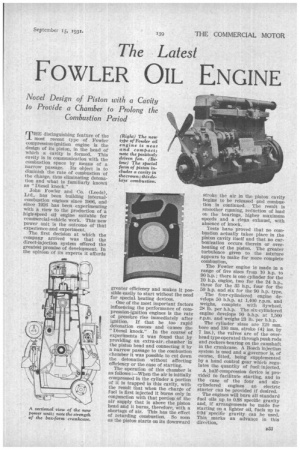

THE distinguishing feature of the ' most recent type of Fowler compression-ignition engine is the design of its piston, in the head of which a cavity is formed. This cavity is in communication with the combustion space by means of a narrow passage. Its object is to diminish the rate of combustion of the charge, thus eliminating detonation and what is familiarly known as "Diesel knock."

John Fowler and Co. (Leeds), Ltd., has been building internalcombustion engines since 1906, and since 1926 has been experimenting with a view to the production of a high-speed oil engine suitable for commercial-vehicle work. This new power unit is the outcome ofthat experience-and experiment.

The first decision at which the company arrived was that the direct-injection system offered the greatest promise of development. In the opinion of its experts it affords greater efficiency and makes it possible easily to start without the need for special, heating devices.

One of the most important factors influencing the performance of compression-ignition engines is the rate of pressiire rise immediately after ignition. If that be too rapid detonation ensues and causes the "Diesel knock." In the course of experiments it was found that by providing an extra-air: chamber in the piston head and connecting it by a narrow passage to the combustion chamber it was possible to cut down the detonation without affecting efficiency or the ease of starting.

The operation of this chamber is as follows :—When the air is initially compressed in the cylinder a portion of it is trapped in this cavity, with the result that when the charge of fuel is first injected it burns only in conjunction with that portion of the air supply that is above the piston head and it burns, therefore, with a shortage of air. This has the effect of retarding combustion. So soon as the piston starts on its downward stroke the air in the piston cavity begins to be released and combustion is continued. The result is smoother running, reduction of load on the bearings, higher maximum 'spends and a clean exhaust, with absence of knock.

Tests have proved that no combustion actually takes place in the piston cavity itself and that no carbonization occurs therein or overheating of the piston. The greater turbulence given to the mixture appears to make for more complete combustion.

The Fowler engine is made in a range of five sizes from TO h.p. to 90 h.p. ; there is one cylinder for the 10 h.p. engine, two for the 24 h.p., three for the 35 h.p., four for the 50 h.p. and six for the 90 h.p. type.

The four-cylindered engine develops 50 b.h.p. act 1,400 r.p.m. and weighs, complete with flywheel, 28 lb. per b.h.p. The six-cylindered engine develops 90 b.h.p. at 1,500 r.p.m. and weighs 23 lb. per b.h.p.

The cylinder sizes are 120 mm. bore and 180 ram. stroke (41 ins. by 7 ins.), the valves are of the overhead type operated through push rods and rockers bearing on the camshaft in the crankcase. A Bosch injection system is used and a governor is, of course, fitted, being supplemented by a hand control gear which regulates the quantity of fuel. injected.

A half-compression device is provided to facilitate starting, and in the case of the four and sixcylindered engines an electric starter can be provided if desired.

The engines will burn all standard fuel oils up to 0.88 specific gravity and, if arrangements be made for starting on a lighter oil, fuels up to 0.94 specific gravity can be used. This marks an advance in this direction,