A Much Lighter

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

GARDNER OIL ENGINE

A New Power Unit, Lighter, Smaller and Much More Powerful than the L2 Model, Introduced Specially for _ Passenger Vehicles

TAERE are now about 200 of the Gardner L2-type heavy-oil engines in use driving vehicles on the British roads. The maker, L. Gardner and Sons, Ltd., Pericroft, Manchester, is an old-established company and the engine which it has for many years been producing for marine and stationary purposes has, with but minor modifications, proved remarkably satisfactory in road vehicles. The L2 type is made in any number of cylinders up to six, with a bore of

ins, and a stroke of 6 ins, and develops about 12.5 b.h.p. per cylinder. It was described in our issue dated September 23rd, 1930, and has frequently been referred to since.

As hinted by this journal long ago, the company has been carrying out prolonged research work with the aim of developing an even more refined unit for passenger vehicles, especially for the double-saloon . motorbus. This new engine has• now reached the production stage and we have, at the first possible opportunity, examined it and witnessed bench tests.

Four, Five or Six Cylinders.

The LW engine, as it is called, is available in four, five or six cylinders, with capacity of 5.6, 7 or 8.4 litres and R.A.C. rating of 29, 36.25 or 43.5 h.p., the development being respectively 68, 85 or 102 b.h.p. The governed speed is 1,700 r.p.m. as against 1,350 r.p.m. in the type.

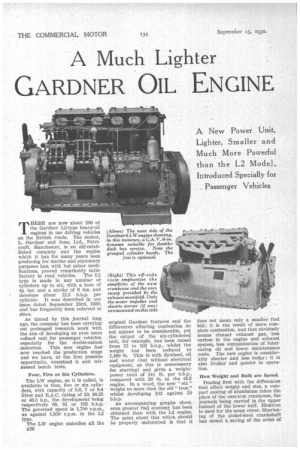

The LW engine embodies all the B26

original Gardner features and the differences affecting combustion do not appear to be considerable, yet the output of the six-cylindered unit, for example, has been raised from 75 to 102 b.h.p., whilst the weight has been reduced to 1,480 lb. This is with flywheel, oil and water (but without electrical equipment, as this is unnecessary for starting) and gives a weightpower ratio of 14i lb. per b.h.p., compared with 26 lb. in the 6L2 engine. In a word, the new " six " weighs no more than the old "four," whilst developing 102 against 50 b.h.p.

As accompanying graphs show, even greater fuel economy has been obtained than with the L2 engine. The point about this which should be properly, understood is that it does not mean only a smaller fuel bill; it is the result of more complete combustion, and that obviously means cleaner exhaust gas, less carbon in the engine and exhaust system, less contamination of lubricating oil and lower maintenance costs. The new engine is considerably shorter and less bulky ; it is also livelier and quieter in operation.

How Weight and Bulk are Saved.

' Dealing first with the differences that affect weight and size, a compact casting of aluminium takes the place of the cast-iron crankcase, the journals being carried in the upper instead of the lower half. Elektron is used for the sump cover. Shortening of the nickel-steel crankshaft has meant a saving of the order of

50 lb. in its weight. The bearings are a shade shorter, but of bigger diameter, giving greater area ; the webs are practically disc shaped. There is one more main journal than there are cylinders in each type of engine. About 1 ft. is saved in the length of the six-cylindered model, this measuring 4 ft. 8 ins, to the rear face of the flywheel, so that, with a protruding flywheel housing, a bulkhead-to-radiator measurement of 4 ft. is possible. The overall height Is 3 ft. 41 ins., the height above the crankshaft centre being 2 ft. 4 ins.

Weight has not been economized on the flywheel; this component, still weighing about 200 lb., is of steel instead of cast-iron. The cylinders are east in blocks of three and two (to suit four, five or sixcylindered engines) and are of a special hard iron. Liners are not fitted, but provision is made for reboring to take dry liners.

The cylinder heads, which on the L2 engine are separate, are cast in groups of three and two and have aluminium covers ; pistons and connecting rods are unchanged, the former being a 2L8 aluminium alloy with four pressure and two scraper rings and weighing 3 lb. 3 oz. each, whilst the latter are of steel, drilled to provide forced lubricatioo to the full-floating 11-in. gudgeon pins, and weigh, without big-end cover, 5 lb. 5 oz. each.

Forced lubrication to all working parts is effected by a gear-type pump through duplicate strainers. An interesing patented feature is that the oil supply to the overhead valve-rocker ends, push rods and valve stems is metered according to the width of a flat machined on the top surface of each rocker, the flats on the exhaust rockers being wider

than those on the inlet rockers. The overall length of a group of rockers for three cylinders is 10i ins.

The modifications which account for the improved performance include alterations to such things as the. valve diameters and timing, port and passage contours, etc. The special inlet valve, with tangential location to ensure turbulence, is symmetrical with the exhaust valve, whilst the easy sweep of the passages in the exhaust manifold is noticed from an accompanying picture. The governor, through which the fuel pump is controlled " and which automatically varies the quantity of the -fuel charge to suit the load, remains unaltered ; like' wise the fuel pinup itself, this having Bosch rams and liners and Gardner tappets and cams. Injection is, of course, direct and the differential injectors, which are centrally located, are of exactly the same type as used in all kinds of Gardner engine; the sprayer valve is a simple piece of mechanism and calls for no adjustment by the user. The same simple variable-compression device permits of easy handstarting, as in the 12 engine.

Electric Starter Unnecessary.

An electric starter is an optional fitting, and when it is fitted it is pleasing for the driver to know that if his battery should be " down " there is no diffaculty in starting from cold by hand. The helical gear wheel of the pump shaft is driven from the camshaft, and helical splines between this wheel and its shaft permit of advancing the injection time by sliding the wheel longitudinally; this is effected automatically and gives a variation of about 8 per cent. The camshaft is driven by a triple roller chain which has an eccentrically mounted ball-bearing adjusting sprocket. The water impeller, driven by a spiral gear from the camshaft, is the only component, apart from the electric starter, to be mounted on the off side.

The compression ratio is unchanged at 13 to 1, the fuel-injection pressure being, at maximum, about 2,000 lb. per sq. in. The governed speed range is from 350 to 1,700 r.p.m.

On the bench the engine idles with hardly any "Diesel knock" and the sound of the fuel passing the injector valves can be distinctly heard—in fact it is the most notice able noise at idling speeds. Acceleration when running light is also particularly quiet. There is, too, a remarkable absence of knock when the engine is under full load at any speeds down to about 400 r.p.m., when, it may be noted, the torque is about 315 lb.-ft. The smoothness at 1,700 r.p.m is excellent and the general liveliness most satisfactory. We. carefully watched the exhaust at all speeds ; it was only just visible, indicating a high degree of combustion. lee temperature of the exhaust gas at the port, incidentally, is only 500 degrees C.

The company has no intention of discontinuing manufacture of the L2 power unit, for which it anticipates a continuation of the present increasing demand, this engine being well suited to heavy goods-carrying vehicles. Indeed, in the shops we saw scores of L2 engines in the process of manufacture. Whilst making a tour of inspection we noted that the company has its own foundry where practically all the castings are made.