CAN THE CHAIN CASE BE IMPROVED?

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

An Authority on Chain Transmission Contends in this Article that the Merits of Chain Drive Justify an Effort to Produce a Better Chain Case.

TEW merits of chain transmission as compared with other forms of drives cannot be proved or disproved by discussions in which partisanship forms the principal feature, so it is not my intention to join in the discussion on the subject which has recently taken place in the pages of The Commercial Motor.

That the chain drive has certain good Ipoints those who have the control of mixed fleets will, I feel sure, agree. I notice, in such fleets, and where the conditions of work vary, that the chaindriven vehicles are usually chosen for the roughest work. In the fleets of some of the large contracting firing one usually sees the chain-driven lorries sent to jobs where they have to go down into excavations, or where extra heavy or awkward loads, such as long girders, have to be carried. The shaft-driven vehicles seem to be kept for journeys on good roads. The reason for this is, I understand, that the chain-driven lorries get on better on rough jobs, but, being noisy and old-fashioned in appearance, are not favoured for use in the main streets of cities.

Against the chain I see two outstanding points, namely, noise and wear. If these two main objections could be minimized. I see no reason why the chain should not return to popularity, for all but the lightest types. Even then we cannot overlook the Trojan, in which a chain forms the method of transmitting the power to the rear axle and is highly satisfactory.

There is little doubt that the chain suffers greatly from the fact that the position in which it is usually placed is near to the wheels,, where it receives a

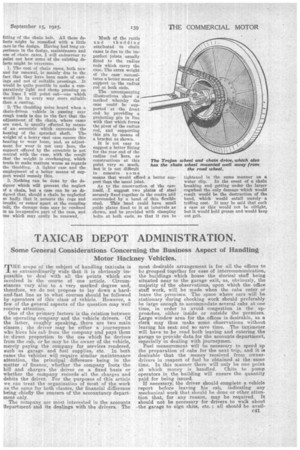

CAO continual bath of mud and grit. Where its use has been attended with success, namely, on the Foden and the Trojan, this result can be accounted for by the fact that it is situated farther from the wear clearly proves that this difficulty can be, and has been, overcome. In the case of the Trojan there is no differential, so that %, matters have been even easier.

I think we may take it that, with many years of acquired experience, everything • that is possible has been done by the chain makers to produce a chain that offers the greatest resistance to the presence of grit; so we may abandon all hope of ever getting a chain that will give better results in the exposed position in which • it usually works.

It would seem that, if the good points which the Chain possesses are to be utilised, we must look for some means' whereby the two objections, wear and noise, can be reduced. I think that the foregoing remarks tend to show that a better position of the ' chain produces

better results, but in Nome constructions this may not be, convenient or easy to • , attain; so in that case we must look to other means of reducing the trouble. The outstanding alternative seems to be the, chain case. Two well-known and proved models have been made in which chain cases have been employed, namely, the Commer Car and the Hanford. Both these models have been on the market for many years and, so far as I am aware, little has been' done in the way of improvement in the design of the chain case. To design a satisfactory chain case is by no means easy, but things that era not easy are done every day, so why not produce a better chain case, and thus in one stroke overcome the other objection?

The faulty I have found in chain cases are as follow :--(1) They are costly in the first place and expensive to renew; (2) they thud when passing over uneven roads ; (3) they often get broken through neglect to keep the chain reasonably tight or through improper Stting of the chain bolt. All these defects might be remedied with a little eare in the design. Having had long experience in the design, maintenance and ase of chain eases, I will endeavour to point out how some of the existing defects might be overcome.

I. The cost of chain cases, both new and for renewal, is mainly due to the tact that they have been made of castings and not of suitable pressings. It would be quite possible to make a comparatively light and cheap pressing on the lines I will point out—one which would be in every way more suitable than a casting.

2. The thudding noise heard when a ebain-driven vehicle is pawing over rough roads is due to the fact that the adjustment of the chain, where cases are used, is usually effected by means of an eccentric which surrounds the bearing of the sprocket shaft. The weight of a heavy cast case causes this bearing to wear loose, and, as adjustment for wear is not easy here, the Support offered by the eccentric is not central with the case, with the result that the weight is overhanging, which Lends to make matters worse as regards the thudding. A lighter ease and the employment of a better means of support would remedy this.

3. Nothing can be done by the designer which will prevent the neglect of a chain, but a case can be so designed that, should a chain be neglected so badly that it mounts the cogs and breaks, or comes apart at the coupling bolt, the damage done may be confined to an inexpensive part of the case, and one which may easily be renewed, Muds of the rattle and thudding attributed to chain cases is due to the imperfect joints usually ftted to the radius rods which carry the case. The extra weight of the case necessitate.s a better means of support to the radius rod at both ends.

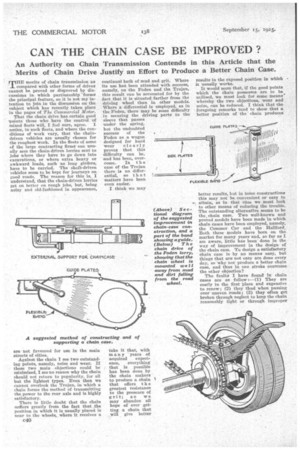

The accompanying illustrations show a method whereby the case mild be supported at the front end by providing a projecting pin in line with that which forms the pivot of the radius rod, and supporting this pin by means of a bracket as shown.

It is not easy to suggest a better fitting for the rear end of the radius rod here, as constructions at this point vary so much, but it is not difficult to conceive some means that would afford a better support than the usual joint As to the construction of the ease itself, I suggest two plates of steel securely fixed together in the centre and surrounded by a band of thin flexible steel. This band could have small guide plates fixed to it at intervals as shown, and be provided with clamping bolts. at both ends, so that it can be

tightened in the same manner as a water clip. In the event of a chain breaking and getting under the larger cogwheel the only damage which would result would be the destruction of the band, which would entail merely a trifling cost. It may be said that such a ease as this would not be oiltight, but it would hold grease and would keep out grit.