FORD DA 2418/CRANE FRUEHAUF 24-TON-GROSS ARTK

Page 47

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

by Gibb Grace, DAuE, CEng, MIMechE.

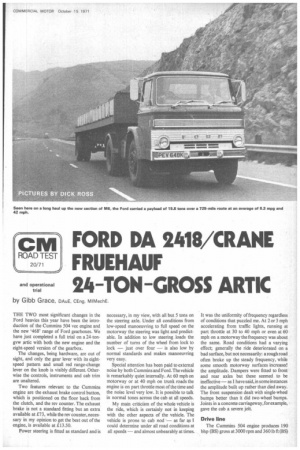

THE TWO most significant changes in the Ford heavies this year have been the introduction of the Cummins 504 vee engine and the new '468' range of Ford gearboxes. We have just completed a full trial on a 24-tongvw artic with both the new engine and the eight-speed version of the gearbox.

The changes, being hardware, are out of sight, and only the gear lever with its eightspeed pattern and small red range-change lever on the knob is visibly different. Otherwise the controls, instruments and cab trim are unaltered.

Two features relevant to the Cummins engine are the exhaust brake control button, which is positioned on the floor back from the clutch, and the rev counter. The exhaust brake is not a standard fitting but an extra available at £73, while the rev counter, necessary in my opinion to get the best out of the engine, is available at £13.50.

Power steering is fitted as standard and is necessary, in my view, with all but 5 tons on the steering axle. Under all conditions from low-speed manoeuvring to full speed on the motorway the steering was light and predictable. In addition to low steering loads the number of turns of the wheel from lock to lock — just over four — is also low by normal standards and makes manoeuvring very easy.

Special attention has been paid to external noise by both Cummins and Ford. The vehicle is remarkably quiet internally. At 60 mph on motorway or at 40 mph on trunk roads the engine is on part throttle most of the time and the noise level very low. It is possible to talk in normal tones across the cab at all speeds.

My main criticiim of the whole vehicle is the ride, which is certainly not in keeping with the other aspects of the vehicle. The vehicle is prone to cab nod '— as far as I could determine under all road conditions at all speeds — and almost unbearably at times.

It was the uniformity of frequency regardless of conditions that puzzled me. At 2 or 3 mph accelerating from traffic lights, running at part throttle at 30 to 40 mph or even at 60 mph on a motorway the frequency was about the same. Road conditions had a varying effect; generally the ride deteriorated on a bad surface, but not necessarily: a rough road often broke up the steady frequency, while some smooth motorway surfaces increased the amplitude. Dampers were fitted to front and rear axles but these seemed to be ineffective — as I have said, in some instances the amplitude built up rather than died away. The front suspension dealt with single-wheel bumps better than it did two-wheel bumps. Joints in a concrete carriageway, forexample, gave the cab a severe jolt.

Drive line

The Cummins 504 engine produces 190 bhp (BS) gross at 3000 rpm and 360 lb ft (BS) torque at 1900 rpm and gives the 24-ton-gvw vehicle a better than average performance and — as I shall discuss later — not at the expense of fuel consumption. Driving through the Ford eight-speed range-change gearbox and an Eaton double-reduction rear axle it produces good acceleration times and very good gradeability. Using second, fourth, fifth, sixth and seventh gear, 40 mph could be reached repeatedly in about a minute. Although we did not take a time to 50 mph, this was reached in under one mile from a standing start on more than one occasion.

The gearbox is very simple to use. Gears one to four are in the form of an 'H', and when fourth is reached the driver flicks the range change lever from low to high and changes into the first gear position, which becomes fifth gear, while sixth is superimposed on second, seventh on third and eighth on fourth. Changing down is just the reverse: when in fifth ready to change into fourth, the range-change lever is flicked to low and the gear moved to fourth. An interlock device allows the range-change to take place only when the lever is in neutral, therefore when missing gears on a change down, for example, the gear lever must go through neutral for the range-change to work. A change from eighth gear to fourth, for instance, is the same position in the box but the range-change switch must be flicked to low and the gear lever put into neutral to effect the change. In practice the rangechange is so positive and the synchromesh so good that only a few miles driving were needed to master it fully.

On motorways only three gears, sixth, seventh and eighth were ever needed except for the steep "slow lorries" section near Loughborough where fifth was needed to maintain 24 mph. Between junctions 36 and 37 on M6, minimum speed was 31 mph in sixth with an average of 38 mph and between junctions 38 and 39 minimum speed was 34 mph in seventh; again the average speed for the section was 38 mph.

The power available and top gear ratio were such that long sections were completed at 60 mph on part or virtually closed throttle. A measure of this cruising ability is shown by the average speed for all motorway sections. The 402 miles of motorway on the test were covered in 7hr 17min — an average of 55 mph.

The two hill climbs on trunk roads that were timed during our trial showed improvements over the Perkins-engined D1000 tested in 1970 (CM January 16). But on the test hills at MIRA where hill starting ability was being checked a half-shaft broke while the vehicle was in the works driver's hands. Ford's engineering department gave me the maximum gradeability for this model, when rolling at maximum gvw, as 19 per cent, and the break occurred on a I in 5 test hill (20 per cent).

A new half-shaft was fitted and the test continued the next day without mishap. On the third day, however, having already successfully climbed Carter Bar and Riding Mill, another half-shaft broke while climbing Castleside. This hill brings the vehicle speed down very quickly and the driver has to work fast to be in the right gear. The works driver (who again happened to be at the wheel at this time) had changed into second but the road speed quickly dropped to a crawl and first was needed; he let out the clutch to take up the drive and this was when the half-shaft went.

It took just over three hours to get labour and a part to us and a further one and half hours to get us mobile. While we were waiting we checked the gradient with a Tapley meter, at 1 in 5, and noticed that most drivers stopped at the foot, selected bottom gear and climbed slowly but surely to the top. Having fitted the new half-shaft we rolled the vehicle back about 30yd on to a I in 6 section and set off again. The vehicle pulled away smoothly and within a few yards the engine was against the governor. The climb was completed v:rithout further ado. At the top when on the level of the climb, we stopped for a few minutes while the mechanics checked the oil level in the sump; once topped up we resumed the test.

At the time of writing, Ford engineers have been unable to establish the precise reason for the two half-shaft failures, though there was a suspicion that there might have been a material batch problem; examination of the company's service records shows only one half-shaft failure on a tractive unit in about the past two years.

Fuel consumption

The overall fuel consumption for the 729mile route was 8.3 mpg for an average speed of 42.0 mph. This figure is creditable when compared with the 1970 D1000 test mentioned earlier, the equivalent results for that vehicle being 7.7 mpg at an average speed of 39.2 mph. In fact, in most instances the DA2418 achieved faster stage times, yet with better fuel consumption.

The actual test route has changed owing to the M6 extension (replacing Shap and Carlisle) but if we neglect the section from Forton Service Area to Gretna the remainder of the route is common and comparison valid. The fuel used, total time and payload for the two vehicles are given below. Total distance Total time D1000 650 17hr 13min DA2418 650 15hr 50min Total fuel Payload DI000 85.15gal 15.9 tons DA2418 78.90gal 15.8 tons The ton mile/gal factor works out at 107.5 and 130 respectively. This factor does not reflect the improved time of the DA2418 and if we consider a ton mile/gal/hr factor the difference in performance is even more marked. These work out at 6.24 and 8.20 respectively. This means that considering both time and fuel consumption as factors the DA2418 is 25 per cent more productive than the D1000.

To sum up in a few words, the DA2418 is a very good vehicle by any standards with regard to sheer performance. Its standard of equipment, seats and trim is high and its appeal to the driver can only be marred by its annoying ride characteristic.

The basic price for the tractive unit is £3472, to which must be added £180 for the fifth-wheel coupling. Several extras were fitted to the test machine, eg the front towing jaw and pin at £13.50 and the factory paint finish at £27.00.