A NEW 12-TON SIX-WHEELER

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Added to the Range of Leyland Goods Models

An Exclusive Account of the Hippo, a Threeaxled Machine of High Power and Efficient Braking, Intended for the Express Haulage of Heavy Loads on Trunk

Highways.

• ONE of the most impressive goods vehicles which

‘../ will be exhibited at the Commercial Motor Transport Exhibition at Olympia, in November, is the new Leyland Hippo model, to which a brief reference was made in our issue for last week. We are now able to give our readers full and exclusive details of this twelve-tonner which has been introduced by Leyland Motors, Ltd., of Leyland, Lanes, in pursuit of that company's well-defined and far-seeing policy of providing a thoroughbred machine of each type for which There is an established 'demand.

With trunk goods services in their present stage of development, a better time could not have been chosen to market a road machine which, with its good tractive adhesion and load distribution, its overhead-camshaft engine and its six-wheel power-aided brakes, can carry its heavy load with speed, safety and silence.

Before entering upon a description of the chassis we feel it necessary to draw special attention to the fact that the engine is one—the largest—of the Leyland company's range of standardized power units. Great ,importance attaches to this. All the Leyland engine models, for current passenger and goods vehicles and for new goods chassis to be introduced, are of one design. All, except the fire

engine models, have the same stroke, namely, 5i ins. In fact, the only important difference is in the bore.

Four-cylindered and six-cylindered units all possess the same features wherever possible and many parts are, therefore, int erchangeable.

The several innovations and detail improvements which we shall enumerate apply, almost without exception, to every model.

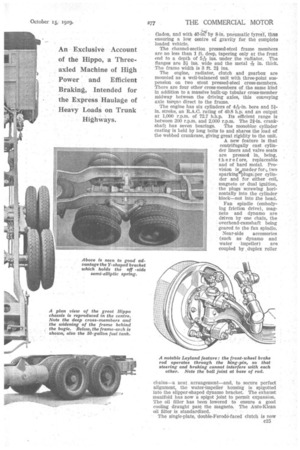

Turning now to the Hippo chassis, this is a rigid six-Wheeler, with a four-wheeled driving-unit, the frame being' level from the front to the bogie and there arched to the extent of 81 ins. Except at the arch the frame top is only 2 ft. 71 ins, above ground level c24

(laden, and with 40-in. by 8-in. pneumatic fyreiY, thus ensuring a low centre of gravity for the pompleto loaded vehicle.

The channel-section pressed-steel frame members are no less than 1 ft. deep, tapering only at the front end to a depth of 5-h. ins, under the radiator. The flanges are 3/ ins. wide and the metal ize in. thick. The frame width is 3 ft. 21 ins.

The engine, radiator, clutch and gearbox are mounted as a well-balanced unit with three-point suspension on two stout pressed-steel cross-members. There are four other cross-members of the same kind in addition to a massive built-up tubular cross-member midway between the driving axles, this conveying axle torque direct to the frame.

The engine has six cylinders of 4-in. bore and 5/in. stroke, an R.A.C. rating of 49.8 h.p. and an output at 1,000 r.p.m. of 72.7 b.h.p. Its efficient range is between 200 r.p.m. and 2,000 r.p.m. The 21-in, crank

shaft has seven bearings. The monobloc cylinder casting is held by long bolts to and shares the load of the webbed crankcase, giving great rigidity to the unit.

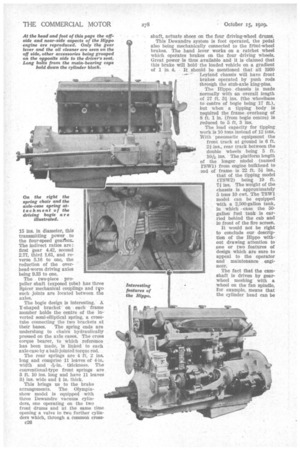

A new feature is that centrifugally cast cylinder liners and valve seats are pressed in, being, t her ef ore, replaceable and of hard metal. Provision is mader fort, two sparking plugs: per cylinder and for either coil, magneto or dual ignition, the plugs screwing horizontally into the cylinder block—not into the head.

Fan spindle (embodying friction drive), magneto and dynamo are driven by one chain, the overhead-camshaft being geared to the fan spindle.

Near-side accessories (such as dynamo and water impeller) are coupled by. duplex roller chains—a neat arrangement—and, to secure perfect alignment, the water-impeller housing is spigotted into the slipper-shaped dynamo bracket. The exhaust manifold has now a spigot joint to permit expansion. The oil filler has been lowered to ensure a good cooling draught past the magneto. The Auto-Klean oil filter is standardized.

The single-plate, double-Ferodo-faced clutch is now c25

At the head and foot of this page the offside and near-side aspects of the Hippo engine are reproduced. Only the gear lever and the oil cleaner are seen on the off side, other accessories being grouped on the opposite side to the driver's seat. Long bolts from the main-bearing caps

hold down the cylinder block.

15 ins. in diameter, this transmitting power to the four-speed• geartox. The indirect ratios are: first gear 4.42, second 2.77, third 1.61, and reverse 5.16 to one, the reduction of the overhead-worm driving axles being 9.33 to one.

The two-piece propeller shaft (exposed tube) has three Spicer mechanical couplings and tvo such joints are located between the axles.

The bogie design is interesting. A Y-shaped bracket on each frame member holds the centre of the inverted semi-elliptical spring, a crosstube connecting the two brackets at their bases. The spring ends are underslung to chairs hydraulically pressed on the axle cases. The cross torque bearer, to which reference has been made, is linked to each axle case by a ball-jointed torque rod.

The rear springs are 4 ft. 2 ins. long and comprise 11 leaves of 4-in.

width and thickness. The conventional-type front springs are 3 ft. 10 ins, long and have 11 leaves 3* ins, wide and # in. thick.

This brings us to the brake arrangements. The Olympia

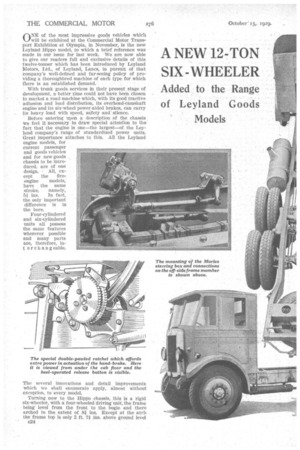

show model is equipped with three Dewandre vacuum cylinders, one operating on the two front drums and at the same time opening a valve to two further cylinders which, through a Common cross c26 shaft, actuate shoes on the four driving-wheel drums.

This Dewandre system is foot operated, the pedal also being mechanically connected to the front-wheel brakes. The hand lever works on a ratchet wheel which operates brakes on the four driving wheels. Great power is thus available and it is claimedthat this brake will hold the loaded vehicle on a gradient of 1 in 4. It should be mentioned that all 1930 Leyland chassis will have front brakes operated by push rods through the stub-axle king-pins.

The Hippo chassis is made normally with an overall length of 27 ft. 31 ins. (the wheelbase to centre of bogie being 17 ft.), but when a tipping body is required the frame overhang of 8 ft. 1 in. (from bogie centre) is reduced to 5 ft. 3 ins.

The load capacity for tipping work is 10 tons instead of 12 tons. With pneumatic equipment the front track at ground is 6 ft. 21 ins., rear track between the double wheels being 5 ft. 10* ins. The platform length

of the longer urtodel (named rswi) from engine bulkhead to .nd of frame is 22 ft. 51 ins., that of the tipping model (TSW2) being 19 ft. 7i ins. The weight of the chassis is approximately 5 tons 10 cwt. The TSW1 model can be equipped with a 2,500-gallon tank, in which case the 50gallon fuel tank is carried behind the cab and in front of the fire screen.

It would not be right to conclude our description of the Hippo without drawing attention to one or two features of design which are sure to appeal to the operator and maintenance engineer.

The fact that the camshaft is driven by gearwheel meshing with a Wheel on the fan spindle, for example, means that the cylinder head can be

removed without the need for disturbing the chain which drives the auxiliaries. Valves can then be ground at the bench instead of on the chassis.

One of the features of the 2I-in. crankshaft is the mannpf in which the crankpin-lightening holes are drilled ; as each hole is eccentric to the pin it is possible to drill it to a large diameter without weakening the shaft where the pin joins the web and it is therefore more effective in reducing centrifugal loads. The holes act as receptacles ,for sludge, and, being of large diameter, need not be cleared so often as is customary. .

Another point is that the clutch (which is equipped with a clutch stop) can be kept in adjustment throughout its life by a single wingnut which is accessible through the cab floor.

We would like to stress the beautifully light steering that results from the use of the Marles gear in conjunction with roller thrust races and large journal bearings for the

king-pins. Considering the size of the vehicle it amounts to a revelation in steering comfort.

Speaking of comfort, we are reminded of the cowl which forms an air tunnel around the power unit from the radiator to the back of the cab. This is formed of asbestoslined sheet metal and, whilst aiding in the cooling of the engine, it prevents the heat from being felt by driver and mate.

The Hippo is not a complicated machine but a simply designed and well-balanced goods carrier which, whilst fulfilling a heavy duty, will give the maintenance foreman no problems.