ZF eases the shift

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

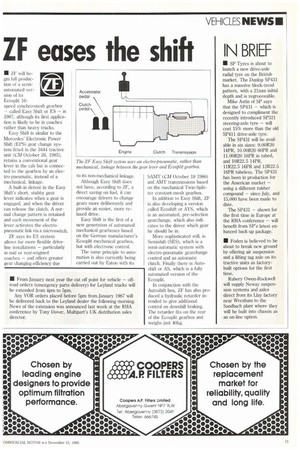

• 'LP will begin full production of a semiautomated version of its Ecosplit 16speed synchro-mesh gearbox — called Easy Shift or ES — in 1987, although its first application is likely to be in coaches rather than heavy trucks.

Easy Shift is similar to the Mercedes' Electronic Power Shift (EPS) gear change system fitted in the 1644 tractive unit (CM October 26, 1985), retains a conventional gear lever in the cab but is connected to the gearbox by an electro-pneumatic, instead of a mechanical, linkage.

A built-in detent in the Easy Shift's short, stubby gear lever indicates when a gear is engaged, and when the driver can release the clutch_ A normal change pattern is retained and each movement of the lever activates the electropneumatic link via a microswitch.

ZF says its ES system allows for more flexible driveline installations — particularly in mid or rear-engined coaches — and offers greater gear changing efficiency due 411•11111h. Fla to its non-mechanical linkage.

Although Easy Shift does not have, according to ZF, a direct saving on fuel, it can encourage drivers to change gears more deliberately and provide an easier, more relaxed drive.

Easy Shift is the first of a new generation of automated mechanical gearboxes based on the German manufacturer's Ecosplit mechanical gearbox, but with electronic control.

The same principle to automation is also currently being carried out by Eaton with its SAMT (CM October 18 1986) and AM'I' transmissions based on the mechanical Twin-Splitter constant-mesh gearbox.

In addition to Easy Shift, ZF is also developing a version called Ecoshift or AVS, which is an automated, pre-selection gearchange, which also indicates to the driver which gear he should be in.

More sophisticated still, is Semishift (SES), which is a semi-automatic system with electro-pneumatic gearchange control and an automatic clutch. Finally there is Autoshift or AS, which is a fully automated version of the Ecosplit.

In conjunction with the Autoshift box, A? has also produced a hydraulic retarder intended to give additional control on downhill braking. The retarder fits on the rear of the Ecosplit gearbox and weighs just 40kg.