An Ingenious

Page 80

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

" Easy-change" Device

New Warren Mechanism Incorporating a Free Wheel and Synchronizing Dogs. Full Clutch Withdrawal Isolates Gearbox

-flESICNED for mounting behind the gearbox, an ingeni ous easy-change gear named the Warren is being marketed for commercial vehicles by the Pulsorneter Engineering Co., Ltd., 39, Victoria Street, Westminster, Loudon, S.W.1, and is now on view at Olympia on the company's stand (No. 199).

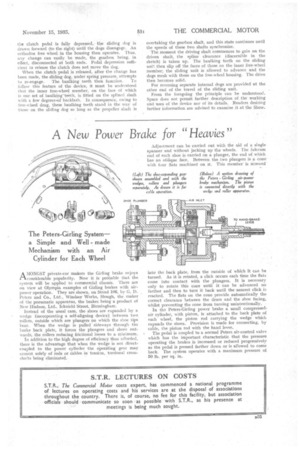

The accompanying group of sketches shows the fundamental parts and explains the working of the baulking teeth. The hollow splined shaft, seen in the central view, is an extension of the gearbox mainshaft, and can rotate independently of the body of the device which is formed as a. unit with the short output shaft, seen behind it on the left.

Under normal conditions, a solid drive is afforded, the " forward dogs" being engaged. So soon, however, as E54

the clutch pedal is fully depressed,, the sliding dog is drawn forward (to the right) until the dogs disengage. An orthodox free wheel in the housing then operates. Thus, any change can easily be made, the gearbox being, in effect, disconnected at both ends.. Pedal depression sufficient to release the clutch does not move the dog. When the clutch pedal is released, after the change has been made, the sliding dog, under spring pressure, attempts to re-engage. The baulking teeth then function. To follow this feature of the device, it must be understood that the inner free-wheel member, on the face of which is one set of baulking-teeth, is fitted on the splined shaft with a few degrees-of backlash. In consequence, owing to free-wheel drag, these baulking teeth stand in the way of those on the sliding dog so long as the propeller shaft is overtaking the gearbox shaft, and this state continues until the speeds of these two shafts synchronize. The moment the driving shaft commences to gain on the driven shaft, the spline clearance (discernible in the sketch) is taken up. The baulking teeth on the sliding unit then slip off the faces of those on the inner free-wheel member; the sliding unit is allowed to advance and the dogs mesh with those on the free-wheel housing. The drive then becomes solid. For reversing separate internal dogs are provided at the other end of the travel of the sliding unit. From the foregoing the principle can be understood. Space does not permit further description of the working and uses of the device nor of its details. Readers desiring further information are advised to examine it at the Show.