WE TEST A PRODUCER-GAS PLANT.

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Road and Bench Performances of the Tulloch-Reading Outfit, which has been Improved in Many Details and is Practically Automatic in Action.

ALTHOUGH the recent imposition, by the Chancellor of the Exchequer, of a 4d. per gallon tax upon highly volatile fuels has naturally made all big consumers of the precious fluid think more seriously of alternatives, it is, as yet, difficult to see quite how a gas-producer plant could really, with advantage, he used in this: country. The . case overseas, however, is quite -different. There, large tracts of laud, quite undeveloped in so far as railroads are Concerned, abound. Petrol is scaree, a fact which, in itself, forces up the price Of the commodity,. whilst in 'addition heavy transportation Charges cause a further increase,, that is, of course, reflected in the running costs of the vehicles concerned. Add to this the very rapid evaporation of light fuels

due to the tropical heat of certain of the countries and it will be realized that the position M almost intolerable.'

In Many •places--such as the cottonproducing countries, for instance—railroads are often several hundreds of miles apart, and waterways are equally scarrce ; thus the generally accepted alternative to petrol—steam—is heavily discounted, especially when it is barne in mind that coal is also a rarity. Indeed, most of the locomotives operating In these parts are fired with wood ; Consequently a huge fuel tender is a sine qua non. Now this is where the producer plant steps into the breach. The consumption of water is very small, as will be realized by a perusal of the test report which is included in this article. charcoal, the fuel from which the gases

040 are made, is, as most people know, very plentiful in tropical countries; where natives use it as a medium for cooking and heating.

Most people interested in the internalcombustion engine have a fair idea of how a producer-gas plant " works," but few really understand more than the firSt principles; and Still fewer have

any or much knowledge of running costs.For the benefit of those readers of The Commercial Motor who are interested in the development of this fuel we have recently -completed a comprehensive test, both on the test bench and on the road, of the Tulloch-Reading Plant..

Let Letus now briefly examine the, producer-gas system as applied to a 2

ton .Guy lorry. In the first place, it must be accorded that the plant itself is very unobtrusive. Two things are responsiblefor this, one is that everYthing has been done to keep the bulk of the apparatus down to the smallest possible dimensions commensurate with

efficiency, and the other is that the plant has been so arranged that no inroads have been made in the body space, thereby• baring the platform area the same as in the ordinary petrol-fuelled vehicle. All essential components are nevertheless accessible.

)3y moving the driver's cab bodily towards the off side space has been made for housing the generator on the near side, where it is enclosed by a swing door. The hopper for carrying the fuel is very neatly incorporated in the head structu,re of the cab, and the feed pipe and fuel-control valve are so arranged as to be well out of harm's way, although they can be easily inspected.

It would be as well at this juncture to describe how the plant operates. Fuel is fed into the producer from the hopper by gravity through a form of valve which is slowly rotated by ratchet gear, so that when an aperture coincides with the supply line a barreltype container is filled with fuel. As . this container is rotatedfarther, the a'perture communicates with a vertical chute running into the firebox. The valve has a tapered seating, the two elements (the movable and the fixed portions) being held together by a simple clamping arrangement which spring-loads the surfaces of the coatings. The edge of the aperture in the barrel of the valve is so shaped that any fuel which happens to lie between the two approaching faCes of the valve and its housing is chipped into small pieces, thereby making certain that the valve can always close. Surposing, however,

that a piece of wood inadvertently becomes lodged in the valve barrel, a seizure is then prevented from doing serious harm by a double-acting spring • which is instituted in the rocker arm operating the valve.

Water is supplied to a vaporizer, located 'above the firebox, through the medium of a small pump, which can, if desired, be operated by hand.

Thermostatic control bas been arranged to regulate the quantity of air and steam delivered to the producer.

As might be expected, the fire-bars have to be rocked constantly in order to allow the clinker, cinders and dust to pass into the ash bcix. The motion flit. this -operation, together with the

water-pump drive and the rotary ratchet action for the fuel-supply valve, is taken from some convenient point of the power unit.

The gas is first ,delivered to what is known as a centrifugal dust extractor. The purified gases are then taken to a battery of four scrubbers located at the rear of the vehicle. One of these scrubbers contains deflector baffles, the second is loosely packed with wood wool, whilst the third and fourth, coupled in parallel to the second, are tightly packed with wood wool. Of these, more anon. The system is completed by a pipe leading to the inlet manifold of the engine. From the time that a match was first put to the, paraffin-soaked cottonwaste in the firebox to the time when the engine was running upon the gas occupied but a trifle more than 9 mins. —a very creditable performance. The engine—a four-cylindered Guy of 4/-in, bore and with a piston stroke of 5if ins. —had a compression ratio of 6.5 to 1, which, of course, is very much greater than that normally employed. Due to the difficulty entailed in swinging an engine of this size with such a high compression ratio, a small choke carburetter was fitted so that the unit could be started up on petrol and the effect of a very low compression pressure obtained.

Once started up, the engine would idle perfectly satisfactorily on the producer gas and it was also found to be capable of rapid acceleration without misfiring or choking, providing that the extra air valve was operated in con junction with the throttle. On the road very little difference could be detected between the "producer gas" engine and a " petrol " engine.

The road-test route lay along the

main road from the Guy Works at Wolverhampton to Bridgnorth. With a load of 21, tons, plus three or four passengers (the full capacity of the vehicle), it was found to be possible easily to maintain an average running speed of 20 m.p.h. Over most of the course the top gear of 8.3 to 1 sufficed to convey the vehicle up hill and down dale.

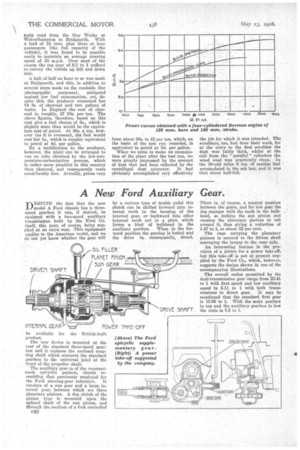

A halt of half an hour or so was made at Bridguorth, and this, in addition to several stops made on the roadside (for photographic purposes), mitigated against low fuel consumption, yet, despite this, the producer consumed but 74 lb. of charcoal and two gallons of water, In England the cost of charcoal is, roughly, £7 10s, per ton. The above figures, therefore, based on this cost give a fuel charge of 5s., which is slightly more than would be the equivalent cost of petrol, At 80s. a ton, however (as it is overseas), the fuel would eost but Is., which is roughly equivalent to petrol at 4d. per gallon.

By a modification to the producer, however, the plant can be arranged to run on coke obtained by the low-temperature-carbonization process, which -is rather more plentiful in this country than charcoal, and consequently costs consitlerably less. Actually, prices vary from about 30s. to £2 per ton, which, on the basis of the test run recorded, is equivalent to petrol at 5d, per gallon.

When we came to make an examination of the plant after the test run, we were greatly impressed by the amount of dust that had been collected by the centrifugal dust extractor. It had obviously accomplished very effectively the job for which it was intended. The scrubbers, too, had done their work, for at the entry to the first scrubber the dust was fairly thick, whilst at the exit from the " parallel" cylinders the wood wool was practically clean. In the 30-odd miles 9 ins, of residue had accumulated in the ash box, and it was then about half-full.