Tractive units are important, but it's trailers that carry the

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

goods that pay the hills. As Steve Banner reports, it is vital that drivers put safety first when working with them.

0 n the face of it, curtainsider trailers are far safer than tippers or tankers. They have their own hazards, however, and should be fitted with a few simple safety devices in order to minimise accidents, warns Grahame Potter, technical director at curtainsider builder Boalloy.

These include grab handles and retractable steps so a driver doesn't have to scramble onto the load deck using the tyre as a rung, and can climb back down again rather than having to jump. Flatbed trailers, like all trailers where the driver has to gain access from ground level—and rigid bodies for that matter—should be equipped in the same way

Back injuries

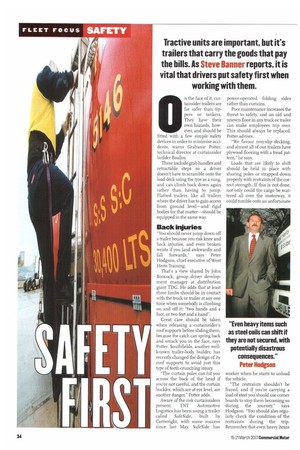

"You should never jump down off a trailer because you risk knee and back injuries, and even broken wrists if you land awkwardly and fall forwards," says Peter Hodgson, chief executive of West Hefts Training.

That's a view shared by John Boocock, group driver development manager at distribution giant TDG. He adds that at least three limbs should be in contact with the truck or trailer at any one time when somebody is climbing on and off it: "two hands and a foot, or two feet and a hand".

Great care should be taken when releasing a curtainsider's roof supports before sliding them, because the catch can spring back and smack you in the face, says Potter. Southfields, another wellknown trailer-body builder, has recently changed the design of its roof supports to avoid just this type of teeth-crunching injury.

"The curtain poles can hit you across the back of the head if you're not careful, and the curtain buckles, which are at eye level, are another danger," Potter adds.

Aware of the risk curtainsiders present, TNT Automotive Logistics has been using a trailer called SafeSide, built by Cartwright, with some success since last May. SafeSide has power-operated folding sides rather than curtains.

Poor maintenance increases the threat to safety, and an old and uneven floor in any truck or trailer can make employees trip over. This should always be replaced, Potter advises.

"We favour non-slip decking, and almost all of our trailers have plywood flooring with a tread pattern," he says.

Loads that are likely to shift should be held in place with shoring poles or strapped down properly with restraints of the correct strength. If this is not done, not only could the cargo be scattered all over the motorway, it could tumble onto an unfortunate worker when he starts to unload the vehide.

"The restraints shouldn't be frayed, and if you're carrying a load of steel you should use corner boards to stop them becoming so during the journey," says Hodgson. "You should also regularly check the condition of the restraints during the trip. Remember that even heavy items such as steel coils can shift if they are not secured, with potentially disastrous consequences."

Roping and sheeting a load requires particular care, and the trailer should be parked in a sheltered spot away from the wind wherever possible, he adds, If you're wrestling with a heavy sheet in a howling gale there's a strong risk that you will lose your balance and fall.

Tanker operators are especially conscious of the need to preserve drivers from harm, especially if they have to get on top of the tanker barrel for access to the man-lids, says Chris MacRae. training manager and policy manager for dangerous goods at the Freight Transport Association.

Safety rails

They ensure that safety rails are fitted and that the driver is attached to the trailer with a tethered line to prevent him tumbling off if he slips when he's going up the ladder or moving along the catwalk at the top," he says.

Access gantries that the driver can use instead of climbing to the top of the tanker are now in widespread use at loading and discharge points.

Enacted under the Health & Safety at Work Act, the Workplace Health, Safety and Welfare Regulations oblige ill employers to take pre-autions to ensure workers don't fall from heights and injure themselves, says MacRae. One approach is to arrange things so that people don't have to work way above ground level in the first place.

"Tanker operators are moving towards bottom-loading of product, and away from top-dipping," he points out For some time tipper operators have used load sheeting systems that can be operated by a driver standing next to the trailer rather than climbing up it; Harsh is one of the major suppliers. They cost Li,000-D,5oo: a further f1,000 will buy an electric version that can be operated from within the cab.

Casually walking behind a truck or trailer is one of the most hazardous activities of all. The Health & Safety Executive estimates that about 7o people are killed and r,000 seriously hurt every year by vehicles manoeuvring in the workplace. About 25% of the deaths involve drivers reversing.

However, vehicles can be fitted with a variety of aids to mitigate the risk, induding reversing bleepers. They cost f3o-L4o installed, are wired through the reversing light circuit and bleep whenever reverse gear is engaged. An alternative is to fit a sensor that will detect the presence of an object and sound a warning in the cab. These use ultrasonics or microwaves, and cost froolzoo fitted. Suppliers of reversing aids include Autosonics, Brigade Electronics and Proximeter.

"Always get out of the cab and look behind the vehicle before you reverse, and wherever possible ask somebody to guide you backwards," is the sensible advice from TDG's John Boocock.

All transport depots should have dearly delineated walkways, warning notices and barriers to prevent the unwary wandering into the path of a reversing artic. Mirrors should be mounted on the walls at appropriate points and adequate lighting installed, especially around loading docks, and people who have to work around trailers should be provided with high-visibility jackets.

Drivers and other employees who are issued with protective clothing—gloves, steel-capped boots, a safety helmet and so on—must use them, Hodgson insists. "It's all too easy to say, `Oh, this will only take me a minute so I won't bother putting it on', and the result can be a nasty injury," he adds.

It's an employer's duty to ensure that such clothing is worn when necessary and that safety procedures are adhered to at all times, according to Stuart Gemmell, technical director at trainers Driving Services.

"Drivers might have been shown the right way to do things when they were first recruited—if they were lucky—but there's every likelihood that they will have forgotten," he says. "So the health and safety message has to be reinforced again and again, through training if necessary, and the rules must be policed."

If this isn't done and an employee suffers injury it will be the boss's hard luck as well as his, Gemmell warns. It's highly likely that he'll sue for compensation, and that his lawyer will argue that his client has received no safety training since he first joined the company several years previously, even though the trucks, trailers and working practices have all changed since.

Civil suit

A civil suit might be the least of an employer's worries, If, say, there is a bad injury caused by an attic backing up, the company could be prosecuted by the Health & Safety Executive under the Health and Safety at Work Act if it has failed to lay down a safe reversing policy. Recent court cases have imposed fines of more than /25o,000. What's more, corporate manslaughter proceedings could be brought against the directors of the firm.

"At TDG we trained 3,500 of our own employees last year, and every person who drives a vehicle or operates a lift truck has to undergo at least one day's training annually," says Geoff Binnington, development manager of safety and training services. Given the hazards that beset trailer operation, that's a policy worth emulating.