THE 30-40 CWT. MARATHON CHASSIS.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

A British Production Embodying Many Interesting Features, Including a Power Unit the Cylinders of Which are Cast Integral With the Top Half of the Crankcase.

AN INTERESTING chassis which forms an addition to the list of British commercial motor vehicles has matured in the factory of an old-established motor company in the North of England, to wit, James Walmsley and Co. (Preston), Ltd., Marathon Engineering Works, Preston. This concern, has a reputation of 100 years' standing as high-class coach builders, which work is still being carried on in conjtuiction with the engineering establishment in the fine premises recently acquired. A brief description Of the new chassis, which is designed to carry a net load of 30-40 cwt., was given in the issue of TheCommereial Motor for July 20th last.

The chassis, as a whole, presents a striking appearance, and is the outcome of an expert knowledge of commercialvehicle design, production, and maintenance of many years' standing, the designer having been connected with most of the leading firms in the industry in various capacities.

The engine is a four-cylinder monobloe type with detachable head cylinders and upper half of crankcase cast integral, the crankcase base being of aluminium and easily removable.

A pressure-fed oiling system ia incorporated, with a sight indicator on the dash. Water circulation is effected by

centrifugal pump. Provision is made for electric lighting and starting, which can be fitted as required. The power developed by the engine is 28 h.p. at 1,50a r.p.m., and is transmitted through a Ferodb-lined cone clutch to the fourspeed spur gearbox, the drive being taken_ through flexible disc couplings.

The gearbox is of robust dimensions, and contains gears of ample strength made from K.E. 805 steel, which has a tensile strength of 100 tons. The gear. shaftsare short and sturdy, and are held in Timken bearings, which not only take the bearing loads, hut also provide for the thrust on the teeth when engaging a gear. A large cover plate on the gearbox enablea all the gears to be inspected and removed when necessary.

The gearbo-k, as is also the _engine, is arranged in the chassis on the three-point

suspension principle, which effectually eliminates strain caused by flexing of the frame under any conditions. The drive from the gearbox is taken through another pair of flexible couplings to' the overhead worm of the rear axle. It is as well to mention here

that the foot brake is 6ituated on the fore part of the worm shaft, and by this

means stresses due to brake action are not transmitted through the flexible disc couplings, although the multiplying effect of the worm gear to the road wheels is retained, thereby giving a very eltictent and powerful emerg,ency brake, without having certain of the disadvantages which are caused when it is placed immediately to the rear of the gearbox.

The 'differential gears and driving Shafts are also made from K.E. 805, all of them being oil-toughened. The differential is of the two-pinion type, and the driving shafts are of the fullfloating order, the final drive being taken through driving dogs in the hub caps of the disc pattern wheels.

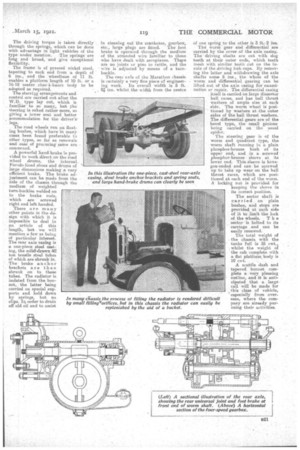

A special feature of the chassis is the radiator, which is of ample size to meet the needs of the engine, and is fitted with a large and much-called for type of filler. The radiator can be filled directly otittolof a bucket, the opening being of oval shape and sufficiently large for this purpose. It is provided with a snapdown lid, making altogether a desirable and neat fitment., which ought to be appreciated by the majority of drivers who have to spend time filling up by means of a watering can from which the nozzle has been removed.

Another interesting feature is that of the cross-steering, which replaces the more orthodox method of a forward push rod. With the former method, the kick of uneven roads is eliminated, so far as the steering wheel is concerned.

No ball thrusts in the ordinary sense are used in the construction of the stub axles, the thrust being taken through hard steel buttons, thereby making single point contact. Where thrust races are fitted, embodying a number of balls, pitting sometimes takes place to such an extent as to render them useless, pockets being formed by the balls, which prevent them turning in the grooved pathway.

Another point of interest in the steering is that no tapers are used to connect the steering arms to the stub axles. In this design they are bolted directly under the stub axle pins, and, incidentally, take the thrust of the Iattel',. The driving torque is taken directly through the springs, which can be done with advantage in light vehicles of the

type wider mention. The springs. are long and• broad, and give exceptional flexibility.

The frame is of pressed nickel steel, tapering to each end from a depth of 6 ins., • and the wheelbase of 11 ft. enables a platform length of 10 ft. or a 16-18 seater .char-a-banes body to be adopted as required,

The steerbg arrangements and control are carried out after the W.D. type lay out, which is familiar to so many, but ,t.be steering is raked rather more, so giiiing a, lower seat and better accommodation for thedriver'slegs.

The road wheels run on floating bushes, which have in many cases been found preferable to other types, so far as renewals and ease of procuring same are concerned.

A powerful hand brake is provided to work direct on the road wheel drums, the internal. Ferodo-lined shoes and drums of large dimensions making .a very

efficient brake. The brake adjustment can be made from the side of the chassis through the medium of weighted turn-buckles welded on to the brake rods, which are screwed right and left handed.

There are many other points in the design with which it is impossible to deal in an article of this length, hut we will mention a few as being of particular interest The rear axle casing is aone-piece steel casting, the solkhd_rawn 40 ten tensile steel tubes of which are shrunk in. The brake anchor brackets are then shrunk on to these tubes. The radiator is isolated from the bonnet, the latter being carried on 'special supports and held down by springs, hut no clips. In order to drain off old oil and to assist in cleaning out the crankcase, gearbox, etc. large plugs are fitted. • The foot brake is operated through the medium of the stranded wire familiar to those who have dealt with aeroplanes. There are no joints or pins to rattle, and the wire is adjusted by means of a turnbuckle. .

The rear axle of the Marathon chassis is certainly a very fine piece of engineering work. Its overall width is 5 ft. 8.; ins, whilst the width from the centre of one spring to the other is 3 ft.2 ins.

The worm. gear and differential are carried by the cover-of the axle casing. The driving shafts are cut with dog teeth at their outer ends, which teeth mesh with similar teeth cut on the inside of the driving hub caps. 13y removing the latter and withdrawing the axle shafts some 5 ins., the whole of the worm and differential, gearing can be lifted out of the axle easing for examination or repair. The differential easing itself is carried on large diameter ball nd has ball thrust washers Of ample size at each side. The worm wheel is positioned by washers at the outer sides of the ball thrust washers. The differential gears are of the bevel type, the small pinions being carried on the usual spider,

The steering gear is of the worm and quadrant type, the worm shaft running in a plain phosphor-bronze bush at its upper end, and in a screwed phosphor-bronze sleeve at its lower end. This sleeve is hexagou-ended and can be screwed up to take up wear on the ball thrust races, which are positioned at each end of the worm. A locking nut is provided for keeping the sleeve in its correct position.

The sector shaft is carried on plain bushes and stops are provided at each side of it to limit the lock of the wheels. T h e seetor • is bolted to its carriage and can be easily renewed.

The total weight of the chassis with the tanks full is 35 cwt,, whilst the weight of the cab completo with a flat platform, body is 10 cwt.

A scuttle dash and tapered bonnet complete a very pleasing outline, and it is anticipated that a. large call will be made for this class of vehicle, especially from overseas, where the company are already pursuing their activities,