STRAIGHT TALKING

Page 108

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

The commercial vehicle crash repair wanted to offer a full industry is being dragged, kicking repair package to the and screaming, into a new age of qualinsurance cornpa ity. At the root of this overdue transformation is an increasingly influential cry from operators and owners for repair and refinishing standards to match those of the automotive industry. In short, they want repairs done quickly and done properly, And why not?

For too long the extent of a body repairer's tool kit was a 20th club hammer and a decrepid old paint brush. Now, thankfully, things are rather different. The new importance of presentation and company image mean that vehicles and liveries really matter.

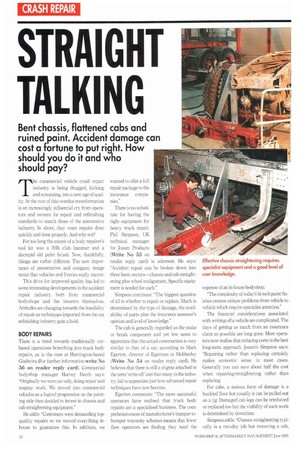

This drive for improved quality has led to some interesting developments in the accident repair industry, both from commercial boclyshops and the insurers themselves. Attitudes are changing towards the feasibility of repair as techniques imported from the car refinishing industry gain a hold.

BODY REPAIRS

There is a trend towards traditionally carbased operations branching into truck body repairs, as is the case at Huntington-based Gladwins (For further information write No 56 on reader reply card). Commercial bociyshop manager Harvey Death says: "Originally we were car only, doing repair and respray work. We moved into commercial vehicles as a logical progression on the painting side then decided to invest in chassis and cab straightening equipment."

He adds: "Customers were demanding topquality repairs so we moved everything inhouse to guarantee this. In addition, we flies."

There is no substitute for having the right equipment for heavy truck repair. Phil Simpson, UK technical manager for josam Products (Write No 55 on reader reply card) is adament. He says: "Accident repair can be broken down into three basic sectors—chassis and cab straightening plus wheel realignment. Specific equipment is needed for each."

Simpson continues: "The biggest question of all is whether to repair or replace. Much is determined by the type of damage, the availability of parts plus the insurance assessor's opinion and level of knowledge."

The cab is generally regarded as the make or break component and yet few seem to appreciate that the actual construction is very similar to that of a car, according to Mark Egerton, director of Egertons in Mobberley (Write No 54 on reader reply card), He believes that there is still a stigma attached to the term 'write off' and that many in the industry fail to appreciate just how advanced repair techniques have now become.

Egerton comments: "The more successful operators have realised that truck body repairs are a specialised business. The comprehensiveness of manufacturer's bumper-tobumper warranty schemes means that fewer fleet operators are finding they need the expense of an in-house bodyshop.

The complexity of today's hi-tech paint finishes creates unique problems from vehicle to vehicle which require specialist attention."

The financial considerations associated with writing off a vehicle are complicated. The days of getting as much from an insurance claim as possible are long gone. Most operators now realise that reducing costs is the best long-term approach. josam's Simpson says: 'Repairing rather than replacing certainly makes economic sense in most cases. Generally you can save about half the cost when repairing/straightening rather than replacing.

For cabs, a serious form of damage is a buckled floor but usually it can be pulled out on a jig. Damaged cab legs can be reinforced or replaced too but the viability of such work is determined by downtime.

Simpson adds: "Chassis straightening typically is a two-day job but removing a cab, pulling it straight on a jig, repainting and refitting can take at least a week." In his opinion very few chassis actually need to be written off because almost any sort of damage (bending. twisting, diamond distortion or vertical) can be put right.

Egerton considers that fewer trucks are being written off these days because operators have at last realised that the tempting prospect of a new replacement is not all it's cracked up to be. He says: "The extra costs of bringing a new vehicle up to an operator's individual specifications (as before) and painting it are rarely matched by the insurance pay out. Usually an operator ends up considerably out of pocket, plus he is faced with the spectre of increased premiums in the future too."

The 'repair rather than replace' thinking is certainly shared by Brian Curness at Andover-based BP Rolls (Write No 53 on reader reply card). "In my experience main agents prefer to put on a new cab while independents like ourselves will opt for a repair. Repairing a cab is 50% cheaper that fitting a new one—rather important when you're talking about a sleeper unit costing perhaps £12,000."

One of the hottest issues at present is the performance of the insurance assessors sent to pass judgement on damaged trucks. Opinons vary greatly on their worth. Harvey Death says: "I've found most to be good and very sympathetic to the vital issue of off-road costs. I know often they get criticised for a lack of specialist knowledge but good assessment should be a two-way process. The assessor must have faith in the repairer's ability and opinions and, assuming this, there should be few problems."

Mark Egerton holds similar views: "Most big insurers have a couple of assessors with good technical knowledge in my experience. I fully appreciate the difficulties caused by the multitude of differing specs and think that building a rapport is therefore the answer."

At the other extreme Brian Curness is not so impressed: "Some assessors I've dealt with have admitted to having very limited knowledge about chassis straightening and how it should be priced."

The problem is that the insurance companies are caught between two markets. The car side of their business is far bigger, and more lucrative, than the truck area. Nevertheless, they are responding. At the Motor Insurance Repair Research Centre, Thatcham, Chris Dyke runs educational courses on truck repair and costing for previously car-only assessors.

Dyke says: "I'm trying to change attitudes here. Teaching assessors not to be daunted by heavy trucks and to appreciate the fact that most cabs can be repaired very successfully are the main objectives." Dyke is well aware of the huge savings to be made by undertaking repairs and admits that the insurance industry is becoming more interested in this aspect of the business. This must bode well for the future.

The Insurance Programme course has been running for four years in conjunction with a more general Repairers Programme (Write No 52 on the reader reply card). The operations will soon be moving to a new centre equipped with the latest Josam equipment so that hands-on heavy truck repair work will be possible for the first time.

The availability of parts plays an important role in the economics of truck repair. Minimising downtime is the key aim. For insurance work most repairers stick with manufacturers equipment, paricularly body panels.

THINNER STEEL

BP Rolls' Brian Curness comments: "We always specify manufacturers panels. The 'copy cat' alternatives are not always 100% and the ones I've inspected seem to be made of thinner steel. I think it's important to stick with the genuine item, particularly with regard to potential liability problems."

Heavy truck repair can be a lucrative operation but the investment required for tooling-up is considerable. Using Josam as an example, the cost of buying well-specified chassis and cab straightening jigs, a light truck system and laser wheel alignment equipment is about £90,000.

The increasingly complicated nature of modern truck design, together with the requirement for accurately fitted panels, even door gaps and top-notch paint jobs, means that putting structural problems right is no longer within the practical grasp of an increasing number of fleet operators.