Tough operating conditions breed tough trucks — and conditions don't

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

come much tougher than in the Finnish logging industry, where 60-tonne Sisu drawbar rigs survive in arctic weather on rough tracks. Brian Weatherley packed his long-johns and headed north

-.I.. to take a drive ...

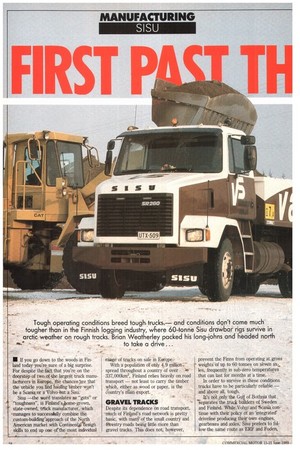

• If you go down to the woods in Finland today you're sure of a big surprise. For despite the fact that you're on the doorstep of two of The largett truck manufacturers in Europe, the chances 'are that the vehide you find hauling timber won't be a Scania or a Volvo but a 8isu.

Sisu —the word translates as "guts" or "toughness", is Finland'sokiome-grown, state-owned, truck manufacturer, which .manages to successfully combine the custom-building approach of the North American market with Continentaltesign skills to end up one of the most individual range of trucks on sale in Europe.

With a population Of only 1.9 million spread throughout a country of over 4D 337,0001en2, Finland relies heavily on. road transport — not least to carry the timber which, either as wood or paper, is the country's irain export.

GRAVEL TRACKS

Despite its dependence on road transport, much of Finnd's road network is pretty basic, with man Y of the small country and frtestry roads being little more than gravel tracks. This does not, however, prevent the Finns from operating at gross weights of up to 60 tonnes on seven ax-,_ les, frequently in sub-zero temperatures that can last for months at a time.

In order to survive in these conditions trucks have to be particularly reliable — and above all, tough. .

Ifs not only the Gulf of Bothnia that ."s'eparates the truck builders of Sweden and Finland. While Volv.p and Scania continue with their policy of an 'integrated' driveline producing their own engines, gearboxes and axles, Sisu prefers to follow the same route as ERF and Foden, using proprietary components — but under its own cab. The exception to this rule is the in-house range of axles.

Buying a Sisu is "like ordering a hamburger in a restaurant", explains market' 'ing manager Hani As,kola. 'You startAp" with a basic truck and build it up from there. It's very much the American idea of custom building."

The principle obviously appeals to local operators, for in the Finnish four-axle heavy truck-market above 22,tonnes GVW Sisu leads the field with a 40.7% share, compared with Volvo's 24.6% and Scania's 22.9%. Within that four-axle/22tonnes-plus market Sisu specialises in the -timber and gravel truck sectors. A truck bought for timber work, which is particularly arduclus, often has a second-hand life rebodied as a gravel truck.

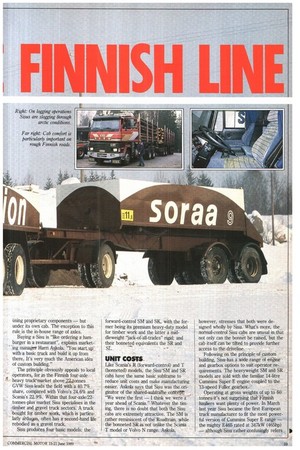

Sisu produces four basic models: the forward-control SM and SK, with the former being its premium heavy-duty model for timber work and the latter a middleweight "jack-of-all-trades" rigid; and their bonneted equivalents the SR and SL.

UtaT COSTS.

LikeScania's R (forward-control) and T (bonneted) models, the Sisu'SM and SR cabs have the same basic subframe to reduce unit costs and make manufacturing easier. Askola says that Sisu was the originator of the shared-subfraffie cotter! "We were the first — I think we were a year ahead of Scania." Whatever the timing, there is no doubt that both the Sisu cabs are extremely attractive. The SM is rather reminiscent of the Roadtrain, while the bonneted SR is not unlike the Scalia T model or Volvo N range. Askola, however, stresses that both were designed wholly by Sisu. What's more, the normal-control Sisu cabs are unusal in that not only can the bonnet be raised, but the cab itself can be tilted to provide further access to the driveline.

Following on the principle of custom building, Sisu has a wide range of engine and gearbox options to suit operator requirements. The heavyweight SM and SR models are sold with the familiar 14-litre Cummins Super E engine coupled to the 13-speed Fuller gearbox' Operating at gross weights of up to 60 tonnes it's not surprising thit Finnish hauliers want plenty of power. In March last year Sisu became the first European truck manufacturer to fit the most powerful version of Cummins Super E range — the mighty E465 rated at 347kW (465hp) — although Sisu rather confusingly refers to it as the C471, based on the engine's 471ps rating. Either way the E465 has plenty to offer, not least the latest Cummins air-to-water Optimised After-Cooling (OAC) charge-cooling system, and the allhydraulic step-timing control (STC) which includes benefits such as improved starting and idling, reduced emissions and lower cylinder pressures at high loads.

For Finnish hauliers who need a little less power, the SM and SR can be specified with the Super E rated at 261 or 298kW (300 or 400hp), and the company is also looking at the latest E365 variants. They all have the 13-speed Fuller box.

WEIGHT RANGE

Moving down the weight range to the SL and SK short/medium range models, Sisu fits either the Cummins L10 or a 7.4-litre Valmet straight-six engine, pushing out 169kW (22'7hp). The L10 lump is available in three power ratings — 187kW and 216kW (250 and 290hp) as in the UK — and also at 246kW (330hp). The latter, however, is different from the LTAA10325 currently offered in Britain by ERF, Foden and Seddon Atkinson, having air-to-water DAC charge-cooling, in place of the UK engine's air-to-air system.

For those hauliers working up around the Arctic Circle Sisu offers heaters for just about everything on the driveline including the engine, engine oil, coolant, differentials, gearbox and obviously the fuel. To go with the L10 or Valmet power unit, Sisu provides a choice of a 13-speed Fuller, 12-speed Twin-Splitter, or nine-speed ZF synchro boxes.

With timber hauliers having to operate frequently on unmade forestry tracks, snow-covered for much of the year, it might be expected that most would want a double-drive rear bogie — but in fact Sisu has gone its own route towards maintaining traction by developing single-driven, twin-axle rear bogies with a trailing axle which can be raised electro-hydraulically, even when the truck is loaded, to transfer a maximum load of up to 15 tonnes onto the hub-reduction drive axle. As the raising axle can also be lifted when the truck is moving it makes for good manoeuvrability, expecially in confined logging roads.

There is another, equally innovative, side to the Sisu bogie axle which is particularly welcome for those working in remote areas. By inserting a special locking pin, the hydraulically-operated tag axle can be lowered while at the same time raising the drive axle by up to 102mm. This is particularly useful if the drive axle becomes bogged down: by raising it off the ground a driver can pack material underneath it to get a better grip, and by alternately raising and lowering axles he can virtually `hop' out of a sticky patch.

While a double-drive axle can be specified along with extra heavy-duty springs, most timber hauliers are more than happy to settle for the single-driven Sisu bogie axle, although to gain extra flexibility many order it with a Robson drive — a small, toothed wheel which can be lowered between the tyres of both axles, allowing drive from the powered axle to be temporarily transferred to the tag axle.

Beside its main company headquarters in Helsinki, Sisu has an axle and specialvehicle assembly plant in Hammeenlinna and its main 8ha assembly site at Kaijaa.

Commercial Motor recently visited the Karjaa plant, which is an intriguing mix of American construction methods, as witnessed by the fully-bolted frames, and a specialised European assembly shop rather like the old pre-Leyland Daf Scammell plant. But Sisu has introduced a fair degree of robotics and automation to the assembly process.

The level of paint protection and cab sealing also needs to be high, as Askola explains: "Rust is a problem for everyone in Finland because of the high levels of salt used on the roads. Sealing has to be done very carefully."

The custom-building process extends from having a full steel cage fitted behind the cab to protect it from log damage, to the fitting of a simple cab phone. Doing the latter at the factory avoids taking the truck back to the workshop to have the roof lining disturbed.

To find out how the Finnish product performs, CM took a turn at the wheel of a wagon and drag outfit consisting of a E465-engined three-axle SM320 with a four-axle trailer. The fully-freighted 22m logging rig tipped the scales at 60-tonnes.

With 346kW on tap the SM320 made easy work of the 60-tonne gross weight — much like 261kW in a 38-tonner — and the long-wheelbased 6 X 2 rigid chassis ensured a good ride as did the comfortable cabin interior. The most noticeable aspect of the whole combination was how stable it was, and how well it drove. With pivot points on the trailer coupling, and on the turntable, the 3+4 outfit needed very little room to turn, and followed the prime mover beautifully.

Pulling out from a right-angle junction onto a main road, however, quickly demonstrated the tremendous drag exerted by the four-axle drawbar trailer. Despite the power of the E465 the change from crawler to first gear had to be made when the drawbar outfit was clear of the junc tion and virtually in a straight line — dip the clutch and attempt the shift too soon when the rig is at an angle and the weight of the trailer acts as an enormous brake.

Given the relatively small size of the truck market in Finland — last year just over 2,000 trucks over 16 tonnes were sold there — the opportunities for internal growth are fairly limited, especially with the stiffening up of competition between Sisu and Volvo in the logging business. "We're fighting them all the time," says Askola — pricing is becoming a more significant factor in the buying process. Volvo can afford to support its activities in Finland with competitive prices, but Sisu can only match them so far without losing out throught its relatively low volumes.

Sisu is fighting back, in the form of a small border raid. Last year it began selling timber trucks in the north of Sweden. It has also been looking beyond Scandinavia for alternative markets, and these could include Australia, where Sisu's nononsense specification could do well.

UK VENTURE

Closer to home, Sisu made tentative attempts to break into the UK market back in 1970 with rigids and tractors powered by Leyland, AEC and Rolls Royce engines. The venture was not successful, but whether the Finnish manufacturer will look again at Britain, considering the fact that it arguably has too many competitors in place already, and the great differences between the two markets remains to be seen. The fact that Sisu is not in the European Community is also a potential handicap to greater Euro sales.

Sisu can, however, draw comfort from the fact that while not a major player in the European truck market, it is at least profitable. It made 63 million Finn marks in 1988 and has a growing presence in military and specialist vehicle markets, with a dock tractor assembly plant in America which could provide a springboard for any truck activities in the US.

Given the competitiveness of its Swedish neighbours and the difficulties in breaking into new markets, Sisu is under no doubt that when it comes to selling trucks outside of Finland it's a cold world out there. But then the Finns are used to the cold.

El by Brian Weatherley