A range to overtake the LP

Page 134

Page 135

Page 136

If you've noticed an error in this article please click here to report it so we can fix it.

The new LP range replacements show considerable advances in driveability and cab refinement. This was much appreciated by Brian Weatherley when he tested the 814 over our 210-mile test route. But he found that fuel economy suffered when he took it to the new light vehicle speed limits

FINDING a vehicle capable of replacing Daimler-Benz's LP light commercial vehicle range cannot have been an easy task. According to Professor Werner Breitschwerdt, Head of DB's research and Development, the model has been 'remarkably successful'.

Well over 300,000 units have been sold. since the LP was introduced 18 years ago. Even in its last full year of production in 1983. it still managed to account for 22 per cent of all the trucks built at Daimler-Benz's Weierth assembly plant.

Few operators would question the fixed-cab 7.5 tonner's durability, but it was long overdue for replacement as its modern competitors were proving more attractive to large fleet operators. Vehicle hire companies in particular, who are among the largest customers in the 7.5-tonne market, are nowadays buying more sophisticated vehicles with car-like cab interiors and driving characteristics tailored to non-hgv driving customers.

It was no surprise that the Mercedes-Benz LN2 range comprising the 809 and the 814 7.5 tonners and the larger 1114 11-tonner should be equipped with a high drive-line specification. The range, launched in the UK in July (CM July 7), offers the options of two new engines and a five-speed synchromesh gearbox as standard.

On top of all this was also a brand new design of light truck cab with which the company no doubt expects the LN2 models to continue well into the 1990's.

First impressions-of the new 7.5-tonne gvw 814 is that it is a real 'drivers vehicle'. To find out its true performance CM took one around its 210-mile Welsh test route. It is only the third 7.5-tonner to go round this route at the

revised light vehicle speed limits.

A number of other transport publications have already tested the 814, but CM is the first to drive one fitted with the standard 3.636:1 rear axle. According to the 814's spec sheet this gives the vehicle a theoretical maximum geared speed of only 67mph. In practice, however, our test vehicle easily held 70 mph on the motorway while on the test track the maximum speed in top gear was 117.5km / hr (73mph).

Equipped with the larger six-cylinder 5.961itre naturally aspirated engine. the 814 is among the most powerful 7.5 tonners on the road. The engine has a maximum output of 100kW (134 bhp) and a maximum torque rating of 402 Nm (296 lb ft). The 809 has a smaller 3.97 litre unit.

This compares with the Bedford TL860 and Iveco 79:14, both with 135 bhp engines and the MAN-VW 8.136 with a 136 bhp unit.

Not surprisingly. it turned in a good journey time at an overall average speed of 73.27km / h (4553 mph).

The new light vehicle speed limits seem to have caught out many commercial vehicle manufacturers. including Daimler-Benz. Per haps preoccupied with top weight tractive unit fuel economies, the company has suddenly been faced with the task of providing its smaller 7.5 tonne vehicles with a rear axle and gearbox flexible enough for low-speed work yet capable of good fuel economy while travelling fully laden at 70mph on the motorway and 60mph on dual carriageways.

Few have achieved this difficult goal so far, and our 814 fitted with a 6.09m (20.0ft) alloy dropside body proved no exception, returning 17.951it/100km (15.73mpg). While this figure may at first glance appear somewhat below average, it is higher than the Ebro 7.5-tonne integral van recently tested (CM Aug 25) which returned 18.41it/100km (15.33mpg) and Iveco 79:14 appraised by CM earlier in the year, which gave 18.651it/100km (15.14 mpg).

Running at 70mph on the motorway at 2.700 rpm it soon became obvious that the 0M366 engine was operating well outside the solid green economy sector marked on the rev counter between 1.600 and 2.200 rpm. In its efforts to maintain maximum speed the 814 was using plenty of fuel. Over the 52.6-mile section of the M4 between Membury and Aust services it could only manage 20.711H/100km (13.64 mpg).

Mercedes-Benz UK is clearly aware of this shortfall in the 814's fuel economy, and although a lower rear axle ratio is not currently available for British models, alternatives to the standard 3.636:1 unit are being looked at. A revised axle may be offered for those operators with high motorway mileages. It would be difficult to convince any driver travelling at 70mph that his engine was running anywhere near flat out as the in-cab noise levels are unbelievably low, being a mere 75dB(A).

Daimler-Benz has spent a great deal of time improving noise insulation the old LP range and it has obviously paid off. At 30mph in top gear the noise reading of 66dB(A) is 4dB(A) less than a 1.6 litre indirect injection diesel powered Fiesta van running at the same speed.

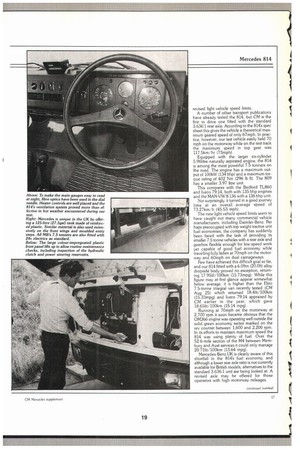

Everything in the 814's cab seems to have been designed to keep the driver as relaxed as possible. The short stubby gear-lever on the familiar MB G3/60-5/7.5 five-speed synchro-gearbox gives fast, positive changes. Even fully laden the 7.5-tonne 814 pulls away comfortably in second without working the dutch hard.

The standard fitted power steering is particularly light. On our comparatively long 4.25m (13.94ft) wheelbase test vehicle it proved invaluable around the narrow twisting streets of Cheltenham and Ledbury. Though DB's power steering does not have quite the same feedback as the excellent Cam Gears unit fitted to the 0609 Ford Cargo tested recently, few drivers, if any, will complain.

Seating on the 814 is typically DaimlerBenz firm but offering excellent support and plenty of individual adjustment. Instrumentation layout has been kept simple and easy to read, and the single multi-function lever on the right of the steering column is straightforward to operate. Although sited at the far right of the dash just inside the cab entry hand grip, the parkbrake lever is within easy reach and has a simple pull-push mechanism.

For £208 operators can specify the optional exhaust brake which, unlike some units, is noticably effective. Its operation, however, is spoilt by the poor positioning of the floor mounted switch which 15 WO far back and difficult to reach.

Access to the 814's cab is particularly good, helped by the low 439mm (17.2in) first step, and the 953mm (37.51n) wide door aperture. Entry is a simple one-two progression using both of the 814's deep set reinforced plastic steps. A driver getting out in a hurry can simply lean out onto the broad topped wheelarch and jump out comfortably.

The adoption of low profile lyres as standard has also enabled Mercedes to reduce the 814's frame height from 870mm to 840mm (34.2-33in) on its 7.5 tonners. Taking into account suspension clearances, a flat-floor bodied 814 (without wheelboxes) has a deck height 85mm lower (3.4in) than previous LP models, giving easier loading and improved stability. On our laden dropside the load deck was 981mm (38.6in) off the ground.

The switch by Daimler-Benz over to full airbraking on the 814 will remove any doubts held by operators about the old LP airassisted hydraulic system. On the test track at MIRA the 814 pulled up quickly and straight with both front wheels locked, while roller brake testing gave a good overall efficiency of 65 per cent slightly higher than the Neap 79.14 recently driven by CM which is fitted with front disc brakes.

The only criticism [make of the system is that on our vehicle the brake pedal had an unnecessary amount of travel before the brakes were applied. This was not helped by the sudden action of the 814's braking system which took time to adjust to.

While the 814's 0M366 engine may not be at its best on the motorway there can be now doubt about its flexiblity at lower speeds, particularly when hill climbing. With maximum torque delivered at 1,400 rpm the 814 will happlily lug down to 1,200 rpm without a down change. Climbing the steepest 1 in 7 test hill on our route outside Wantage, the 814 took 2mins 3sec five seconds faster than the Ebro and a full 11 seconds faster than the rapid 5.69-tonne 0609 downplated Forci Cargo (CM March 10). Only the slightly more powerful lveco 79:14 proved quicker by four seconds.

Overall ride on the 814 is above average helped by the fitting of parabolic springs all round. The soft damping rate, particularly noticable on bumpy roads, may not appeal to all drivers, however.

CM's test vehicle was not equipped with the standard anti-roll bar on the rear axle. Even without it the 814 proved exceptionally stable, exhibiting very little body roll even when cornering hard, despite its long wheelbase and 6.28m (20(t) body. All of those who may have been put off by the LP's old fixed cab will approve of the 814, which can tilt to 45 deg at the roadside and 55 deg in the workshop, allowing plenty of room for servicing and repairs. The torsion bar-counterbalanced day cab can be easily tilted by hand, while sleeper cabs are fitted with an hydraulic lift pump and ram.

For driveability, the 'Mercedes 814 is a match for any vehicle in the 7.5-tonne sector, including the recently introduced lveco 79:14 and Leyland's much heralded Roadrunner.

Its kerbweight is higher than most, as is its price. But for what you pay you get a highly sophisticated vehicle with power steering, fivespeed synchromesh gearbox and full air braking as standard fittings.

For operators with high motorway mileages, the 814s top speed consumption must obviously be considered. However, operating over mixed terrain, good fuel economy can come from good driving technique as well as from a correct driveline specification. Any operator buying the 814 is providing his driver with a working environment likely to improve anybody's productivity.