EIGHT-WHEELERS THE BEST FOR TOUGH TIPPING

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

A 70-vehicle Walsall operator is phasing out all his 32-ton-gvw articulated tipping vehicles in favour of 30-ton gvw rigids. He believes in standardizing on top-quality machines as a means of reducing running costs and in facilitating preventive maintenance by authorizing drivers to assist mechanics by Paul Brockington

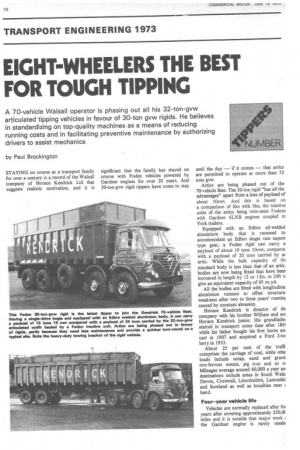

STAYING on course as a transport family for over a century is a record of the Walsall company of Horace Kendrick Ltd that suggests realistic motivation, and it is significant that the family has stayed on course with Foden vehicles powered by Gardner engines for over 20 years. And 30-ton-gvw rigid tippers have come to stay until the day — if it comes — that artics are permitted to operate at more than 32 tons gvw.

Artics are being phased out of the 70-vehicle fleet. The 30-ton rigid "has all the advantages" apart from a loss of payload of about 10cwt. And this is based on a comparison of like with like, the tractive units of the artics being twin-steer Fodens with Gardner 6LXB engines coupled to York trailers.

Equipped with an Edbro all-welded aluminium body that is recessed to accommodate an Edbro single ram export type gear, a Foden rigid can carry a payload of about 19 tons lOcwt, compare( with a payload of 20 tons carried by at artic. While the bulk capacity of tin standard body is less than that of an artic. bodies are now being fitted that have been increased in length by 12 or 13in. to 24ft tc give an equivalent capacity of 45 Cu yd.

All the bodies are fitted with longitudina aluminium runners to offset structura weakness after two to three years' runnint caused by constant abrasion.

Horace Kendrick is director of tb company with his brother William and soi Horace Kendrick junior. His grandfathe started in transport some time after 1861 while his father bought his first horse am cart in 1907 and acquired a Ford 2-to, lorry in 1933.

About 25 per cent of the traffi comprises the carriage of coal, while lathe loads include scrap, sand and grave non-ferrous metals, pig iron and so oi Mileages average around 60,000 a year an destinations include areas in South Wale Devon, Cornwall, Lincolnshire, Lancashii and Scotland as well as localities near hand.

Four-year vehicle life Vehicles are normally replaced after foi years after covering approximately 250,0( miles and it is notable that major work the Gardner engine is rarely neede Average fuel consumption of the rigids is 8/9 mpg which is about 1 mpg better than the average of the astics.

Advantages of the 30-ton rigid over the 32-ton artic, cited by Horace, include greater manoeuvrability, reduced tipping time, lower running costs and the availability of a larger number of weighbridges that can accommodate the vehicle.

Because of its manoeuvrability and "general flexibility" the time spent on sites by an eight-wheeler are on average very considerably reduced compared with the on-site times of artics. And because of this saving, the driver of a rigid takes home as much pay as the Class I driver of an artic whose nominal pay is higher. The only objection of some artic drivers when they are transferred to rigids is that the change represents a loss of prestige.

Horace accepts a power of 180 bhp as suitable for a 30-ton-gvw machine. The customers of a tipper operator who carries low-grade materials won't pay for speed, he observes. And a top speed of 55 mph is regarded as ample for motorways work. A higher top speed would increase wear and tear of the tyres and brakes and the ikelihood of accidents.

The latest Fodens are fitted with the nanufacturer's eight-speed gearbox, older nodels being equipped with the 13-speed ype. While the eight-speed box like the 12-speed unit provides a first gear with a iufficiently low ratio for tipping operations ts well as an approximate spread of ratios or trunking, the nine-speed version would lot be acceptable because of its relatively tigh first gear.

Improvements in site conditions in recent .ears have been favourable to the use of a ingle-drive bogie which reduces wear and :ar in addition to providing a valuable aving in weight. And Horace points out

at a four-spring balance beam suspension )f a type fitted to the Fodens) is virtually a lust for tippers because of the support it gives to the vehicle chassis at its rear end. A two-spring suspension would not give the necessary support.

Radial tubeless tyres

Commenting on the company's use of Michelin radial tubeless tyres, Horace told me that in his view, their outstanding advantage was that they enabled better brake drum cooling to be provided. The tyres are mounted on 22in. wheels, which provides an extra lin. all round of drum cooling space and reduces the heat relayed to the covers. And he favours Michelins over other makes because of their reduced tread depth! While this also reduces the maximum mileage potential of the covers, it is "kinder to the casings" in his view, with the result that a high percentage of worn tyres are acceptable for once-only retreading (by Michelin).

The greater the tread depth, the greater is the heat generated and the amount of heat that the casing has to cope with, and during operations at a sustained high speed on motorways this can accelerate deterioration of the casing. As mentioned earlier, site conditions have improved in recent years and the incidence of damage to tyre treads and casings is less of a problem than it was.

If Kendrick vehicles regularly visited sites strewn with sharp stones or other impediments, they would be fitted with cross-ply tyres, which are more resistant to penetration. Employing tubeless tyres gives a weight saving of about 4cwt per vehicle. Average life is about 50,000 miles, while the normal life of brake linings is around 100,000 miles.

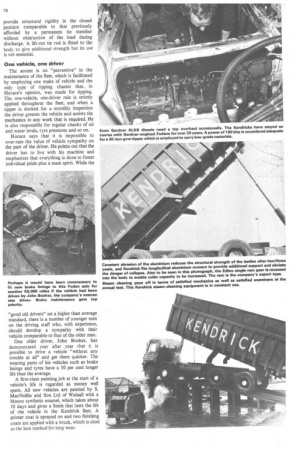

Providing tail doors that do not obstruct unloading and at the same time are not vulnerable to damage has been overcome by using a barn-door assembly that was originally developed in liaison with Edbro and is now produced by that company, one of the bodies on the Edbro stand at Earls Court last year being equipped with Kendrick /Edbro tail doors. Each aluminium door is mounted on three robust steel hinges of the bolt-through type, and the central locking mechanism incorporates a channel-section member hinged to the top rail of the right door, which clamps the rail of the other door when the central operating rod is moved downwards by a lever. This is claimed to provide structural rigidity in the closed position comparable to that previously afforded by a permanent tie member without obstruction of the load during discharge. A lift-out tie rod is fitted to the body to give additional strength but its use is not essential.

One vehicle, one driver The accent is on "preventive" in the maintenance of the fleet, which is facilitated by employing one make of vehicle and the only type of tipping chassis that, in Horace's opinion, was made for tipping. The one-vehicle, one-driver rule is strictly applied throughout the fleet, and when a tipper is docked for a monthly inspection the driver greases the vehicle and assists the mechanics in any work that is required. He is also responsible for regular checks of oil and water levels, tyre pressures and so on.

Horace says that it is impossible to over-rate the value of vehicle sympathy on the part of the driver. He points out that the driver has to live with his machine and emphasizes that everything is done to foster individual pride plus a team spirit. While the "good old drivers" set a higher than average standard, there is a number of younger men on the driving staff who, with experience, should develop a sympathy with their vehicle comparable to that of the older men.

One older driver, John Booker, has demonstrated year after . year that it is possible to drive a vehicle "without any trouble at all" and get there quicker. The wearing parts of his vehicles such as brake linings and tyres have a 50 per cent longer life than the average.

A first-class painting job at the start of a vehicle's life is regarded as money well spent. All new vehicles are painted by S. MacNeillie and Son Ltd of Walsall with a Mason synthetic enamel, which takes about 10 days and gives a finish that lasts the life of the vehicle in the Kendrick fleet. A primer coat is sprayed on and two finishing coats are applied with a brush, which is cited as the best method for long wear.