Vehicle by Preceptor

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

lutches, 5

le clutches described in the evious articles have thrust ,a rings which press against the lease fingers and move them wards the flywheel when the utch pedal is operated to sengage the clutch. The heavy ity clutches made by LipeAway have a release action hich works in the opposite rection, that is the release essure pulls the lever ends vay from the flywheel when e clutch is depressed.

When a clutch is disengaged, ith the engine running, the drill plates tend to keep reliving. With heavy commercial ;hides the size and weight of a driven plates execerbates is problem making the engement of gears difficult. For any years clutch brakes have en fitted to slow down or stop e driven plates when the itch pedal is fully depressed,, Id some pretty crude devices are used in the early days for is purpose.

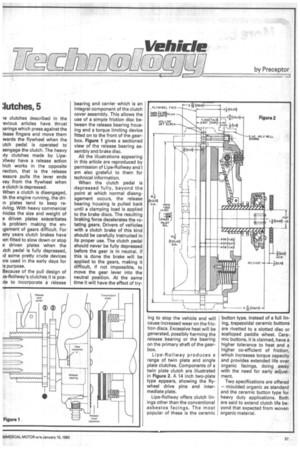

Because of the pull design of 3e-Rollway's clutches it is posile to incorporate a release bearing and carrier which is an integral component of the clutch cover assembly. This allows the use of a simple friction disc between the release bearing housing and a torque limiting device fitted on to the front of the gearbox. Figure 1 gives a sectioned view of the release bearing assembly and brake disc.

All the illustrations appearing in this article are reproduced by permission of Lipe-Rollway and I am also grateful to them for technical information.

When the clutch pedal is .depressed fully, beyond the point at which normal disengagement occurs, the release bearing housing is pulled back until a clamping load is applied to the brake discs. The resulting braking force decelerates the rotating gears. Drivers of vehicles with a clutch brake of this kind should be carefully instructed in its proper use. The clutch pedal should never be fully depressed before the gear is in neutral. If this is done the brake will be applied to the gears, making it difficult, if not impossible, to move the gear lever into the neutral position. At the same time it will have the effect of try ing to stop the vehicle and will cause increased wear on the friction discs. Excessive heat will be generated, possibly harming the release bearing or the bearing on the primary shaft of the gearbox.

Lipe-Rollway produces a range of twin plate and single plate clutches. Components of a twin plate clutch are illustrated in Figure 2. A 14 inch two-plate type appears, showing the flywheel drive pins and intermediate plate.

Lipe-Rollway offers clutch linings other than the conventional asbestos facings. The most popular of these is the ceramic button type. Instead of a full lining, trapezoidal ceramic buttons are rivetted to a slotted disc or scalloped paddle Wheel. Ceramic buttons, it is claimed, have a higher tolerance to heat and a higher co-efficient of friction, which increases torque capacity and provides extended life over organic facings, doing away with the need for early adjustment.

Two specifications are offered — moulded organic as standard and the ceramic button type for heavy duty applications. Both are said to extend clutch life beyond that expected from woven organic material.