A New Lightweight Mechanical Horse

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

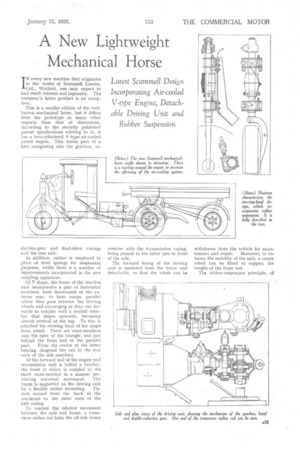

Latest Scammell Design Incorporating Air-cooled V-type Engine, Detachable Driving Unit and Rubber Suspension

IN every new machine that originates in the works of Scammell Lorries, Ltd., Watford, one may expect to find much interest and ingenuity. The company's latest product is no exception.

This is a smaller edition of the wellknown mechanical horse, but it ditfers from the prototype in many other respects than that of dimensions. According to the recently published patent specifications relating to it, it has a two-cylindered V-type air-cooled petrol engine. This forms part of a unit comprising also the gearbox, re duction-gear and final-drive casings and the rear axle.

In addition,rubber is employed in place of steel springs for suspension purposes, whilst there is a number of improvements incorporated in the new coupling apparatus....

Of V shape, the-frame of the tractive unit incinporates a pair of horizontal members, bent downwards at the extreme rear, to form ramps, parallel where they pass between the driving wheels and converging as they run forwards to conjoin with a central member that slopes upwards, becoming almost vertical at the top. To this is attached the steering head of the single front wheel, There are cross-members near the apex of the triangle, and just behind the front end of the parallel

part. From the centre of the latter bracing, diagonal ties run to the rear ends of the side members.

At the forward end of the engine and transmission unit is bolted a bracket, the front of which is coupled to the short cross-member in a manner permitting universal movement. • The frame is supported on the driving axle by a flexible rubber mounting. Tierods extend from the back of the crankcase to the outer ends of the axle casing.

To control the relative movement between the axle and frame, a transverse radius rod links the off-side frame member with the transmission casing, being pinned to the latter just in front of the axle.

The forward fixing of the driving unit is insulated from the frame and detachable, so that the whole can be withdrawn from the vehicle for maintenance and repair. Moreover, to enhance the mobility of the unit, a castor wheel can be fitted to support the 'weight of the front end,

The rribber-suspension principle, of

which Scammell Lorries, Ltd., is a pioneer, is also employed for the front wheel. This is mounted with its vertical diameter approximately in line with the axis of the steering head, provision being made for affording a small degree of castor action. The wheel runs on a short axle, carried on a single unilateral member, secured to the base of the steering-wheel shaft.

The last named turns in a tubular casing, extending the full length of the head, and accommodating bearings to take radial loads. Thrust is withstood by a tapered-roller bearing at the summit, above the worm wheel, by which rotation of the steering wheel is transmitted to the shaft.

Free to move axially for a limited distance, but unable to rotate, the casing has rigidly fixed to it a cup at the lower end of the rubber-suspension bush. The top end of this similarly abuts against the underside of the upper of two steering-head brackets, bolted to the frame pillar referred to earlier.

Both these brackets house frictional shock-damping devices, one of which also performs the function of positively restraining the shaft casing from rotary motion. Briefly, the dampers comprise bearing surfaces faced with friction material, and to each of which pressure is imparted by a wedge acting. through a ball, upon a pivoted arm. The wedges are subjected to a constant force applied by a double-ended leaf spring mounted on the assembly and extending from one bracket to the other.

An attractive feature of this head is the absence from the wheel-carrying member of any complex gear.

Features of the Semi-trailer.

Turning now to the semi-trailer, we find the rubber-suspension and triangulated-radius-rod principle employed also here. The arrangement closely resembles that in the tractive unit, a transverse link on the off side, as before, controlling the movement of the axle relative to the frame.

The turntable and coupling gearconsist, in the main, of an upper and lower turntable member, held together by a central rod, a bracket, on the lower member, carrying under it a transverse beam .(on which is a pair of large flanged rollers) and a retractable undercarriage.

Upon the -tractive unit are mounted a catch and locking mechanism, a pair of buffers, against which the rollers abut, and a fitting for automatically operating the undercarriage. The lastnamed is of the break-back-link type, and is collapsed and lifted by a powerful tension spring.

An ingenious device is incorporated which controls the degree of rocking motion permitted by the turntable. Application of the hand operated trailer brake releases the rod which holds together the turntable members, but normally, when the brakes are off, these members seat firmly, one upon the other, and rocking is in this manner prevented.

The following patent specifications are concerned with this vehicle and kts components: 457,607 (general layout), 457,608 (steering details), 457,609 (frame), 457,618 (air cooling arrangements), 457,653 (coupling and turntable) and 457,792 (transmission unit).