TECHNICAL ASPECTS of t 4ULTI-CYLINDER ENGINE.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The Pros and Cons of Four, Six and Eight Cyli

Smoothness in Runnit

UCH ink has been used and a x AI...great deal of vehemence e

if

pended upon arguments relating to that vexed question on engine design, " How many cylinders—four. six or eight?"' If the private-ear world he anything to go by, opinion seems to iEave taken a definite step towtads +he " six" and at least a halting step towards the "eight.' The reemt Olympia • Show demonstrated these features in no uncertain manner,. for many manufacturers staged new six-cylinder cars of moderate power, and there was quite L number of new "eights" varying in price from f485 to something approaching i2,000 for the complete ears.

Does not this state of affairs give some indication that the general trend of ideas in the whole world of automobilisna is towards an increase in the number of cylinders for power units? The ease for commercial vehicles, of course, requires special. consideration, because the conditionsof service of, say, a bus

engine are so vastly different from those of the general run of private ears. In spite of

this, however, there are many characteristics of the six and eight which, when. investigated, • seem to indicate that there is a great deal to be said in favour Of -these types, and, as the .demands for refinement become more and More insistent; there is 'little doubt hut that attention will be drawn to the advantages offered by the smaller, although higher-powered, multi-cylindered unit.

• The engines of all commercial vehicles, whether of the passenger or goods types, have to work very hard ; much harder, in fact, than the power unit of any private ear. That is to say, any change in design should aim at increasing the life of bearings and all the moving parts, yet the engine must deliver at the flywheel power at least as great as, and preferably greater than, the existing types without necessitating an increase in the piston-swept. volume of the cylinders. 'Another aspect of the case concerns the size of the engine itself. Every square foot of space on a commercial chassis is of great value to the operator consequently, a long engine means lost carrying capacity, which in turn spells lost revenue. Again, the c32

milt must be capable of giving a good 'power output— or, as it is more commonly called, a high torque figure —at low rates of reVointion.speed, because any engine. which does not possess this characteristic is very hard on its clutch, There are many other features which have to be borne in mind, but it would seem oPportune first of all to investigate the merits and disadvan-, tages of the multi-cylindered engine, and then see how the favourable points can be used to advantage, bearing in mind the special requirements of the type of

vehicle under review, • .

It is difficult to .know where to begin a technical, investigation—whether to consider the forces operating on the crankshaft or whether to concern ourselves with the combustion chamber and the effect of size upon therrno-dynande efficiency. The latter aspect seems to he the governing feature, so we will start by considering the 'effect. of valve size, combustionchamber shape and so on.

In the first place, it would be :1,; \veil to consider. the effect of piston size upon the permissible compression ratio whic.h can be used advantageously. In racing engines ratios in excess of 9 to 1 have been used by the writer for short-distance sprint work, -but, of course, such engines need antidetonating fuel and many special features have to be incorporated which make them entirely unsuitable for normal commercial purposes. The average compression ratio nowadays in good modern engines is in the neighbourhood of 5 to I. and even when using quite ordinary commercial fuel very little pinking is experienced.

Now, experience has taught us that as the cylinder bore is decreased so the compression ratio can be raised without increasing the tendency to pink, which, in other words, means that as the number of cylinders for a given capacity of engine is increased, so the compression ratio can be raised also, which in turn means higher efficiency and, other things being equal, a greater. power output. In passing, it might be well to mention that, generally speaking, t ii e high-compression engine does not run hotter than the low -compression type, as is so generally believed, because the mean temperature during the firing stroke is reduced very considerably owing to the longer expansion which takes place when a highcompression pressure is attained. The maximum temperature is greater and so is the highest. pressure, which explains why sparking plugs which stand up quite satisfactorily in a lowcompression engine, often fail when put into an engine having a high-compression ratio. It is entirely erroneous, however, to connect moderately high-compression ratios with 'pinking, detonation and excessive temperatures.

By raising the compression ratio , the engine has a higher thermal efficiency because the area of the combustion chamber is decreased (consequently the jacket. loss is proportionately reduced), but the power output is increased, due to the rise in the mean pressure throughout the stroke. Absurdly high-compressien ratios have to be avoided because the mean pressure throughout the stroke rises quite rapidly at the lower end of the scale and tails off at the upper end or highest ratios, but the maximum pressure increases all the time. It is easy to appreciate, therefore, that a point can be reached where the increase in maximum pressure is not compensated for by a marked increase in mean pressure; thus, the only result of raising the ratio is to increase enormously the loading on the

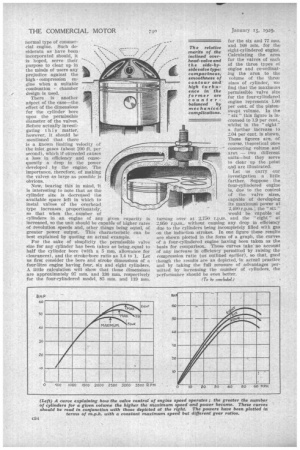

(Above). Eight-cylinder induction systems depend upon the arrangements of the cranks. A two-choke carburetter is used in the type shown in the lower diagram on account of the peculiarly

irregular consecutive firing strokes,

crankshaft journals and big-end bearings of the connecting rods. Such considerations as these, however, 'do not really come within the scope of an article such as this, because the ratios and pressures, where such phenomena become of outstanding importance, are much higher than could be advocated for use in the

normal type of commercial engine. Such desiderata as have been .

incorporated should, it is hoped, serve their purpose to clear up in the minds of users any prejudice against the high compression engine when a suitable combustion chamber design is used.

There is another aspect of the case—the effect of the dimensions for the cylinder bore upon the permissible diameter of the valves. Before actually investigating this matter, however, it should be mentioned that there is a known limiting velocity of the inlet gases (about 200 ft. per second), which if exceeded causes a loss in efficiency and consequently a drop in the power developed, by. the engine. The importance, therefore, of making the valves as large as possible is obvious.

Now, bearing this in mind, It is interesting to note that as the cylinder size is decreased the available space left in which to instal valves of the overhead type increases, proportionately, so that when the, number of cylinders in an engine of any given capacity is increased, so the unit should be capable of higher rates of •revolution speeds and, other .things being equal, of greater power output. This characteristic can be best explained by quoting an actual example.

For the sake of simplicity the permissible valve size for any cylinder has been taken as being .equal to half the cylinder bore (with a 5 ram. allowance for clearances), and the stroke-bore ratio as 1.4 to 1. Let us first consider the bore and stroke dimensions of a four-litre engine having four, six and eight cylinders. A little calculation will show that these dimensions are approximately 97 min. and 136 nun. respectively for the four-cylindered model, 85 nun. and 119 mm. for the six and 77 mm. and 108 mm. for the eight-cylindered engine. Calculating the area for the valves of each of the three types of engine and co-ordinating the area to the volume of the three sizes of cylinder, we find that the maximum permissible valve size for the four-cylindered engine represents 1.66 per cent. of the pistonswept volume. In the " six " this figure is increased to 1.9 per cent., whilst in the " eight." a further increase to 2.04 per cent. is shown. These figures are, of course, theoretical ones

-4connecting volume and

area — two different units—but they serve to clear up the point v,nd are illustrated.

Let us carry our investigation a little farther. Suppose the four-cylindered engine is, due to the Control of the valve sizes, capable of developing its maximuni power at 2,400 r.pin. ; the " six" • would be capable of turning over at 2,750 r.p.m.. and the "eight" at 2,950 r.p.m.,• without causing any drop in efficiency due to the cylinders being incompletely filled with gas on the induction strokes. In one figure these results are shown plotted in the form of a graph, the curves of a four-cylindered engine having been taken as the basis for comparison. These curves take' no account of any increase in efficiency permitted by raising the compression ratio (as outlined earlier), so that, good though the results are as depicted, in actual practice and by taking the full measure of advantages permitted by increasing the number of cylinders, the performance should be even better.