HOW THE GERMANS ARE USING HEAVY FUELS.

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

The Use of Light Fuels Being Avoided as Much as Possible in Germany • Because of Their Cost, the Methods Adopted to Make Heavy Fuels Practicable are Here Described.

THE PUBLIC passenger services of Germany have, as might have been expected, been considerably affected by the shortage of volatile fuels and by the high priees which have ruled for these fuels, following upon the troubles in the Ruhr district and the depreciation of the mark. Prices have gone up to simply exorbitant figures and, whilst financial losses have occurred all round, these losses have been so great in some cases that operating companies have been compelled to shut down their services either wholly or in part.

There has been a considerable.amount of enterprise shown in the engineering and research departments in an endeavour to

utilize some of the heavier grades of fuel produced in gasworks and elsewhere, because some of these fuels can be obtained for a quarter of the prices ruling for benzole and petroleum derivatives. The great difficulty, however, has been to obtain perfect combustion, and the opinion at present ruling amongst those who are carrying out the tests is that this problem will not be satisfactorily solved. It is thought that the smokeless and odourless combustion of these fuels cannot be obtained with the means now in use. Although methods of volatilization in the carburetter and a considerable pre-heating of the mixture have been employed, it is thought more than probable that the adoption of fuel injection, such as in the ease of the petroleum engines recently designed by Bellem and Bregeras, will laaye to be considered; thus involving a system totally different from anything hitherto used.

The tests in connection with the adoption of such a system, however, will occupy considerable time and, whilst waiting for the results of them, other means are being taken to drive engines of public service motor vehicles partly with heavy oils and partly with light oils. Public passenger services have increased to an enormous extent in the past few years, and there is a very strong feeling that every effort should be made to prevent the services from breaking down.

So far, the methods suggested for the use of heavy oils and light oils in the engines are two: first, to use the light fuel as an auxiliary fuel, when the oil vapours and air are compressed in the cylinder in order toignite the heavier portions of the mixture ; and, secondly, to use the light oils only for starting the engines, which, when sufficiently warm, can then run on heavy oils. It has been found that, in the latter case, a small admixture of light fuel is advisable and even necessary.

These two methods have now been adopted by companies having large fleets, and a decided saving in fuel expenses has been recorded. However, the solution of the problem is provided by neither method, because combustion is imperfect and there are many complaints from the public regarding the smell of the exhaust gases. The experimental work has all been carried out. by the service companies, to whom praise is to be given for

the pioneer work thus performed hitherto, assistance from the motor vehicle manufacturers in connection with the work has not been sought. Up to the present, the second method which is mentioned, viz.' using the light fuel for starting and the heavier fuel with a slight admixture of light fuel for running, is the one which is most favoured by the users. Tests have also been carried out with mixtures of cheap fuels, especially by the Motor Car Institute of the Technical High School of Dresden. The Institute has carried out experiments continuously since 1921. What seemed to be the best solutions obtained have been with mixtures of benzoic and petroleum in the ratio of 3 to 7. A carburetter containing a ring-shaped float designed by Schlee of Birkwitz, near Dresden, has been employed for volatilizing the mixture of air, benzole and petroleum and, with an engine developing 19.5 h.p. at 2,016 r.p.m., the fuel consumption was found to be 354grammes per b.h.p.-hour. With a similar mixture (the proportions being those given above) a 35 h.p. Daimler\ engine used to drive a lorry, and running at 985 r.p.m., developed 31.5 hp, on a fuel consumption of 230 grammes per blepehour. There is, thus, a reduction in the maximum output of the engine when using this fuel mixture, and no disadvantage was observed. These experiments, however, have had to be discontinued because of the relatively large proportion of light fuel contained in the mixture.

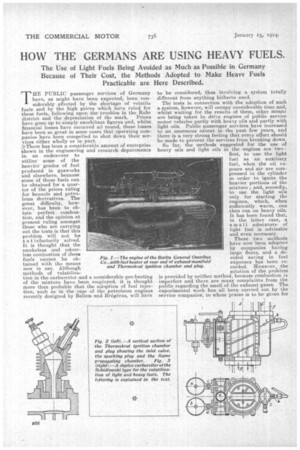

The General Omnibus Co. of Berlin have, for some little time, been running a number of their vehicles on ordinary petroleum, the engines being equipped with a small ignition plug or chamber, designed by the firm of Roholziinder Thermokrat. This apparatus is shown in Fig. 2, and in position on the engine in Fig. 1. It will he seen from Fig. 1 that the petroleum fuel passes through a Vessel east as an extension of the exhaust manifold, a small portion of the mixture being branched off from the main stream and highly heated. The greater portion of the mixture is not so highly heated. The two streams re-unite, and the fuel passes on to the induction pipe, which is water-jacketed so as to prevent recondensetion of the vapour. The heated mixture is taken into the cylinders, and a small portion of light fuel is sucked into the ignition chamber (shown in section in Fig. 2), being supplied from an auxiliary carburetter at every suction stroke of the engine. A flat check valve cuts off the ignition chamber from the suction pipe during the compression strok e. When the contents of the chamber have been ignited, the resultant flame shoots out through t h e lower tapered part of the chamber, igniting the main charge in the cylinder by a process of flame propagation. The tapered orifice of the ignition chamber also has the effect of throttling the suction action of the piston, so that the vacuum in the chamber is not so high as that in the cylinder. In this way the quantity of light fuel drawn into the ignition chamber is reduced to the minimum.

It will be observed that the chamber is furnished with external cooling ribs, which radiate the heat so that it shall not become unduly heated in continuous service. It has been found desirable to keep the temperature of the cooling water fairly high so that the engine shall remain uniformly warm. This is effected by throttling the circulation of the cooling water, either by means of a cock adjustable from the driver's seat, or automatically by means of a thermostat.

Fig. 4.—The carburetter arrangement on the engine of an The results obtained Adler vehicle used by the German State Post, showing the with the buses which screen for the float chamber, the pipe lagging, etc. are provided with em gines thus equipped have been very promising, for the engines have proved to be reliable and there has been a substantial reduction in fuel costs. The latest records in our possession are those of tests made in bad weather, and it is considered that even better results will be obtained under better weather conditions. There is, of course, . a certain decrease of power output owing to the high pre-heating of the charge, ancl efforts have been made to counteract this decrease by increasing the compression up to 1 in se and by employing aluminium pistons. Up to the present the buses have been able to maintain their time schedules, and the only objection so far raised has again been in connection with the odour of the exhaust, and tests are being conducted.mainly with a view to overcoming this difficulty. The German postal authorities run a large number of motorbuses, ears .and lorries on the "overland" route sections and in private service, and they have recently been using heavy oils, again with a view to effecting economy in fuel expense. Some years ,ago, the authorities bought up an old works at Berlin'Borsigwalde, and there created a very extensive and well-organized system of dealing with all current repairs and for the

building of car bodies and trailers. The plant is very comprehensive and is well designed for the job The whole of the "overland" demands for Northern and Central Germany are covered by these works.

For the volatilization of the heavy oils used, the postal authorities employ a duplex carburetter of the Schidlowski type designed by t h e Schiele-Bruchsal Industriekonzern. We illustrate this carburetter in vertical and horizontal sections in Fig. 3; -and show it in position on an engine in Fig. 4. The carburetter has two separate floats a and b, used respectively to control the supply of light fuel and gas-oil, separate air nozzles c and d regulating the supply, of air. There is a tubular valve e, disposed vertically, which is used to .control the supply to the cylinders, the valves being capable of adjustment, and by means of this valve either.a mixture of light fuel or a mixture of volatilized gas-oil and air with a small admixture of light fuel from both carburetters is fed into the common channel g, so that any proportion of mixture that may be desired can be supplied This mixture is carried in spiral turns round a ribbed heater h, through which flow the exhaust gases; of the engine from A to B. The mixture then passes on to the induction pipe of the engine C, and, being continuously heated, the vaporization of the heavy oil is readily effected and recondensation is avoided. The light-load supply to the engine is provided from the nozzle k, above the butterfly valve fight fuel only being supplied through this source. When the butterfly valve is entirely closed there is no suction at all on the orifice of the nozzle k, and directly it is closed the supply automatically changes over to the light fuel. The lever for adjusting the tubular valve e, has only to be operated after a long stop or after running light for some time.

Carburetters of this kind are naturally heavy, and, in the .ease of those supplied for the vehicles of the German postal authorities, they are more than heavy, because they are cast in bronze. To avoid the cylinder castings from being fractured by the stresses due to excessive weight, the carburetters are mounted on special supports and also, •inPorder to conserve the heat, they are invariably mounted on the exhaust side of the engines and are provided with screens to keep off the cold air which passes over the engine. The piping is also covered with insulating asbestos cord.

An examination of Figs 4 and 5 (in the first of which is shown the carburetter arrangement on an Adler engine, and in Fig. 5 on a Daag engine) will show that sharp bends have been avoided in all the piping, because it is at sharp bends where the fuel vapours show the greatest tendency to recondense.

Despite the difficulty experienced in adapting this carburetter to all the different types of vehicles used by the postal authorities, over 200 vehicles have already been equipped with it. So far, the results obtained with the duplex carburetter prove that, ev,en at temperatures below freezing point, vehicles are always ready to start—that is to say, the engines require no pre-heating, whilst the consumption of fuel has been enormously cut down, only a quarter of the light fuel previously employed now being consumed.

Taking, for instance, a 40 h.p. motorbus made by Voigtlamders, tested over a 100-kilometre trial route, it was found that the total consumption was 6.45 kilos. of light fuel and 21.7 kilos. of gas-oil, the proportions, therefore, being 1 to 3, which naturally means a great saving in running expenses. It has

i also been found that, n spite of the high pre-heating of the mixture, the power output of the engine has not been materially decreased, and that gradients can be taken at the same speeds as were possible when light fuels were used. On long runs with uniform load the consumption of the light fuel may be further reduced if the supply nozzle of the duplex carburetter passing the light fuel is completely closed, only gas-oil then being employed, but it is necessary to reopen the nozzle in ample time before the vehicle be brought to rest. There is no doubt that further experimenting with heavy oils should be undertaken also in this country, particularly in connection with the transport of big loads, because fuel costs are still unduly high when one comes to consider that the competition of the railways must become more acute, and we hope that in the course of the next year or two we may be able to record results of experiments similar to these which have been conducted with such promise in Germany.