ANOTHER ENTRANT FOR 1 [X-WHEELER MARKET.

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

TEROUGLIOUT the country British manufacturers of commercial vehicles are giving the closest attention to the developments which are occurring in connection with the design and production of six-wheeled vehicles. It is needless for us here to recapitulate the advantages of the multi-wheeler, particularly as we dealt with many ot these in our Passenger Vehicle Number, published last week.

The production of these new transport media is resulting from two distinct causes. One is the call by users for large-capacity vehicles for passenger services, the other is the demand By the War Department for vehicles which will be equally suitable for road and cross-country employment ; and the new model Vulcan, which we describe in this article, owes its inception to this latter cause, and it remains to be seen whether, with the experience gained with this comparatively light model, the company will eventually develop larger types.

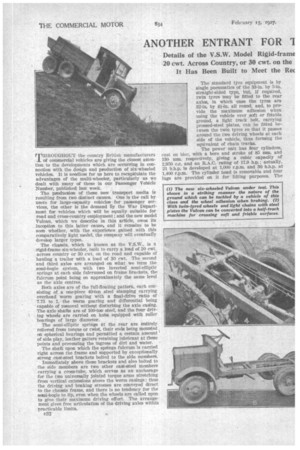

The chassis, which is known as the V.S.W., is a rigid-frame six-wheeler, built to carry a load of 20 cwt. across country or 30 cwt. on the road and capable of hauling a trailer with a load of 30 cwt. The second and third axles are arranged on what we term the semi-bogie system, with two inverted semi-elliptic springs at each side fulerumed on frame brackets, the fulcrum point being on approximately the same level as the axle centres.

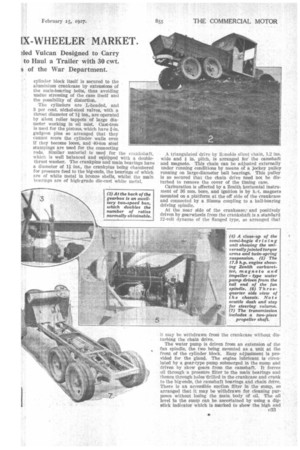

Both axles are of the full-floating pattern, each consisting of a one-piece 40-ton steel stamping carrying overhead worm gearing with a final-drive ratio of 7.75 to 1, the worm gearing and differential being capable of removal without disturbing the axle casing. The axle shafts are of 100-ton steel, and the four driving wheels are carried on hubs equipped with roller bearings of large diameter.

The semi-elliptic springs at the rear are entirely relieved from torque or twist, their ends being mounted on spherical bearings and permitted a certain amount of side play, leather gaiters retaining lubricant at these points and preventing the ingress of dirt and water.

The shaft upon which the springs fulcrum is carried right across the frame and supported by exceptionally strong cast-steel brackets bolted to the side members.

Immediately above these brackets and also bolted to the side members are two other cast-steel members carrying a cross-tube, which serves as an anchorage for the two universally jointed torque arms stretching from vertical extensions above the worm casings; thus the driving and braking stresses are conveyed direct to the chassis frame, and there is no tendency for the semi-bogie to tip, even when the wheels are called upon to give their maximum driving effort. The arrangement gives free articulation of the driving axles within practicable limits.

c32

The standard tyre equipment is by single pneumatics of the 33-in. by 5-in. straight-sided type, but, if required, twin tyres may be fitted to the rear axles, in which case the tyres are 32-in. by 41-in. all round, and, to provide the maximum adhesion when using the vehicle over soft or friable ground, a light track belt, carrying pressed-steel plates, can be fitted between the twin tyres SO that it passes around the two driving wheels at each side of the vehicle, thus forming the equivalent of chain tracks.

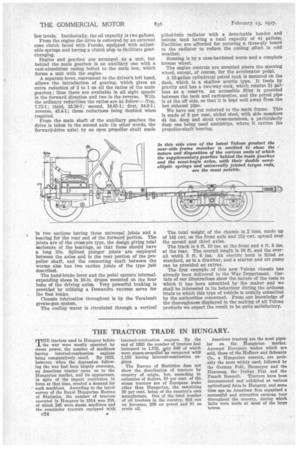

The power unit has four cylinders, cast en bloc, with a bore and stroke of 85 mm. and 130 mm. respectively, giving a cubic capacity of 2,950 c.c. and an R.A.C. rating of 17.9 h.p.; actually, 21 b.h.p. is developed at 1,000 r.p.m. and 30 b.h.p. at 1,400 r.p.m. The cylinder head is removable and four lugs are provided on it for lifting purposes. The

cylinder block itself is secured to the aluminium crankcase by extensions of the main-bearing bolts, thus avoiding undue stressing of the case itself and the possibility of distortion.

The cylinders are L-headed, and 3 per cent, nickel-steel valves, with a throat diameter of 11 ins., are operated by silent roller tappets of large diameter working in oil mist. Cast-iron is used for the pistons, which have i-in. gudgeon pins so arranged that they cannot score the cylinder walls even If they become loose, and 40-ton steel stampings are used for the connecting

rods. Similar material is used for the crankshaft, which is well balanced and equipped with a double

thrust washer. The crankpins and main bearings have a diameter of 11 ins., the crankpins being chambered for pressure feed to the big-ends, the bearings of which are of white metal in bronze shells, Whilst the main bearings are of high-grade die-cast white metal.

A triangulated drive by Ranolds silent chain, 12 ins. wide and in. pitch, is arranged for the camshaft and magneto. This chain can be adjusted externally under running conditions by means of a jockey pulley running on large-diameter ball bearings. This pulley is so secured that the chain drive need not be disturbed to remove the cover of the timing case.

Carburation is effected by a Zenith horizontal instrument of 36 mm. bore, and ignition is by h.-t. magneto mounted on a platform at the off side of the crankcase and connected by a Simms coupling to a ball-bearing driving spindle.

At the near side of the crankcase,' and positively driven by gearwheels from the crankshaft is a standard 12-volt dynamo of the flanged type, so arranged that

it may he withdrawn from the crankcase without disturbing the chain drive.

The water pump is driven from an extension of the fan spindle, the two being mounted as a unit at the front of the cylinder block. Easy adjustment is provided for the gland. The engine lubricant is circulated by a gear-type pump submerged in the sump and driven by skew gears from the camshaft. It forces oil through a pressure filter to the main bearings and thence through holes drilled in the crankcase and crank to the big-ends, the camshaft bearings and chain drive. There is an accessible suction filter in the sump, so arranged that it may be withdrawn for cleaning purposes without losing the main body of oil. The oil level in the sump can be ascertained by using a dipstick indicator which is marked to show the high and

low levels. Incidentally, the oil capacity is two gallons.

From the engine the drive is conveyed by an external cone clutch faced with Ferodo, equipped with adjustable springs and having a clutch stop to facilitate gearchanging.

Engine and gearbox are arranged as a unit, but behind the main gearbox is an auxiliary one with a cast-aluminium casing bolted to the main box, which forms a unit with the engine.

A separate lever, convenient to the driver's left hand, allows the introduction of gearing, which gives an extra reduction of 2 to 1 on all the ratios of the main gearbox; thus there are available in all eight speeds in the forward direction and two in the reverse. With the ordinary reductions the ratios are as follow :—Top, 7.75-1; third, 13.59-1; second, 19.85-1; first, 34.9-1; reverse, 45.4-1; these reductions being doubled when required.

From the main shaft of the auxiliary gearbox the drive is taken to the second axle (in other words, the forward-drive axle) by an open propeller shaft made In two sections having three universal joints and a hearing for the rear end of the forward portion. The joints are of the cross-pin type, the design giving total enclosure of the bearings, so that these should have a long life. Splined plunger joints are employed between the axles and in the rear portion of the propeller shaft, and the connecting shaft between the worms also has two cardan joints of the type just described.

The hand-brake lever and the pedal operate internalexpanding shoes in 16-in, drums mounted on the four hubs of the driving axles. Very powerful braking is provided by utilizing a Dewandre vacuum servo for the foot brake.

Chassis lubrication throughout is by the Tecalemit grease-gun system.

The cooling water is circulated through a vertical gilled-tube radiator with a detachable header and bottom tank having a total capacity of 41 gallons. Facilities are afforded for securing a three-ply board to the radiator to reduce the cooling effect in cold weather.

Steering is by a case-hardened worm and a complete bronze wheel.

The engine controls are mounted above the steering wheel, except, of course, for the accelerator pedal.

A 13-gallon cylindrical petrol tank is mounted on the dash, which is a shallow scuttle type. It feeds by gravity and has a two-way cock, which retains 2/ gallons as a reserve. An accessible filter is provided between the tank and carburetter, and the petrol pipe is at the off side, so that it is kept well away from the hot exhaust pipe.

We have not yet referred to the main frame. This is made of 3 per cent.. nickel steel, with side members 41 ins, deep and stout cross-members, a particularly deep one being used amidships, where it carries the propeller-shaft bearing.

The total weight of the chassis is 2 tons, made up of 141 cwt. on the front axle and 251 cwt. spread over the second and third axles.

The track is 4 ft. 10 ins, at the front and 4 ft. 8 ins. at the rear. The overall length is 19 ft. and the overall width 5 ft. 6 ins. An electric horn is fitted as standard, as is a drawbar, and a starter and air pump can be provided as extras.

The first example of this new Vulcan chassis has already been delivered to the War Department. Certain of our illustrations show the nature of the tests to which it has been submitted by the maker and we shall be interested in its behaviour during the arduous trials to which this type of vehicle is usually submitted by the authorities concerned. From our knowledge of the thoroughness displayed in the making of all Vulcan products we expect the result to be quite satisfactory.