A NEW ENGINE FOR COMMERCIAL WORK.

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

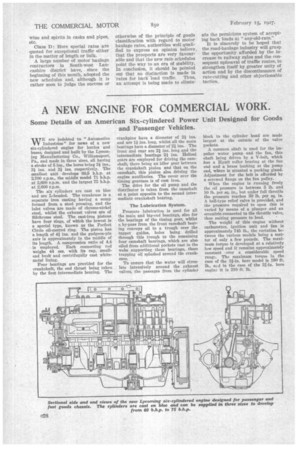

Some Details of an American Six-cylindered Power Unit Designed for Goods and Passenger Vehicles.

WE are indebted to "Automotive Industries" for news of a new six-cylindered engine for lorries and buses, designed and built-by the Lycoming Manufacturing Co., Williamsport, Pa., and made in three sizes, all having a stroke of 5 ins., the bores being 3# ins., 3i ins. and 3# ins. respectively. The smallest unit develops 60.5 b.h.p. at 2,700 r.p.m., the middle model 71 b.h,p. at 2,600 r.p.m. and the largest 75 b.h.p. at 2,600 r.p.m.

The six cylinders are east en bloc and are L-headed. The crankcase is a separate iron casting having a sump formed from a steel pressing, and the inlet valves are made of chrome-nickel steel, whilst the exhaust valves are of Silchrome steel. The oast-iron pistons have four rings, of which the lowest is a special type, known as the Perfect Circle oil-control ring. The piston has a length of 41 ins, and the gudgeon-pin axis is approximately in the middle of its length. A compression ratio of 4.4 is employed. Each connecting rod weighs 44 ozs. with its cap, smallend bush and centrifugally cast whitemetal lining.

Four hearings are provided for the crankshaft, the end thrust being taken by the first intermediate bearing. The trankpins have a diameter of 2# ins. and are 1# ins, long, whilst all the main bearings have a diameter of 21 ins. The front and -rear are 21 ins, long and the intermediate bearings 21 ins. Helical gears are employed for driving the camshaft; there being an idler gear between the crankshaft pinion and that on the camshaft, this pinion also driving the engine auxiliaries. The cover over the timing gearcase is of cast iron.

The drive for the Ml pump and the distributor is taken from the camshaft at a point opposite to the second intermediate crankshaft bearing.

The Lubrication System.

Pressure lubrication is used for all the main and big-end bearings, also for the bearings of the timing gear, whilst a by-pass from the front camshaft bearing conveys oil to a trough over the tappet guides, holes being drilled through this trough to the remaining four camshaft bearings, which are also oiled from additional pockets cast in the webs supporting these bearings, these trapping oil splashed around the crankcase.

To ensure that the water will circulate intensively around the exhaust valves, the passages from the cylinder block to the cylinder head are made largest at the outside of the valve pockets.

A common shaft is used for the impeller water pump and the fan, this shaft being driven by a V-belt, which has a Hyatt roller bearing at the fan end and a brass bushing at the pump end, 'where is situated a packing gland. Adjustment for the belt is afforded by a screwed flange on the fan pulley.

When the engine is running freely the oil pressure is between 5 lb. and 10 lb. per sq. in., but under full throttle the pressure reaches 50 lb. per sq. in. A ball-type relief valve is provided, and the pressure required to open this is varied by means of a plunger and an eccentric connected to the throttle valve, thus suiting pressure to load.

The weight of this engine without carburetter, ignition unit and fan is approximately 745 lb., the variation between the various models being a matter of only a few pounds. The maximum torque is developed at a relatively low speed and it remains approximately constant over a considerable speed range. The maximum torque in the case of the 31-in. bore model is 190 ft. lb., a;:d in the case of the 3I-in. bore engine it is 210 ft. lb.