The Yorkshire Three-tonner.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

The Latest Model Emanating from the Pepper Road Works Presents Several Features of Interest.

Quite apart from the present strained situation with "regard to the supply of petrol, it will be agreed on. all sides that there is a large and growing field of operation for the 3-ton rubber-tired steamer. In. pre-war times, this type of vehicle competed on favourable terms with the petrol-engined lorry for the same load capacity., particularly in point of all-round economy, which was such as in many cases to off-set the disadvantages of time lost in 'steam raising and taking up water. With petrol at the present high figure—when obtainable—the steamer obtains an increased economy, notwithstanding war-time coal prices ; where coke can be burnt, fuel cost is, of course, still further reduced, But considering only general conditions and those of after-the-peace, it is evident that the scope of this type of wagon is widening. There are signs that makers are appreciating this fact.

A well-known and popular steam wagon of a special design is the Yorkshire. Its makers have in one form or another been making steani wagons for 17 years, and the present type is one which has earned encomiums from all classes of user. For a firm engaged upon engineering work to be successful, it is a sine-qua-non that improvements in design and conatruction of its products must be made from time to time as experience ,suggests. The Yorkshire Co. are not backward in this respect.

The newest type of Yorkshire 3ton rubber-tired steamers is a case in point. It is some time now since the first of these was put upon the road and tested, and a considerable period has elapsed even since they were deemed sufficiently successful to be sold as a commercial product ; until now, however, the company has refrained from making public any detail of this design. THE

COMMERCIAL MOTOR therefore presents to its readers at thr.earliest possible moment the fullest particulars of this new departure.

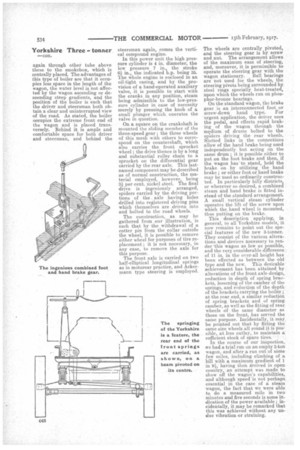

The typical feature of the Yorkshire is, of course, the special design of its boiler ; both externally as affecting the appearance of the wagon, and internally as affecting its utility, efficiency and economy, this component of the wagon marks the Yorkshire as being of a class apart. The arrangement is by now well-known; a brief reminder is all that is now needed. The portion of the boiler containing the tubes is horizontal and runs transversely with regard to the chassis, being placed, as a matter of fact, across the front end of the wagon. In the ,centre, and below, is the firebox. Tubes emerge horizontally from either side of this firebox and run to the ends of the transverse cylindrical portion. The products of combustion and the burning gases then pass inwards again, through other tube above these to the smokebox, which is centrally placed. The advantages of this type of boiler are that it occupies less space in the length of the wagon, the water level is not affected by the wagon ascending or descending steep gradients, and the position of the boiler is such that the driver and steersman both obtain a clear and uninterrupted view of the road. As stated, the boiler occupies the extreme front end of the wagon and is placed transversely. Behind it is ample and comfortable space for both driver and steersman, and behind the

steersman again, comes the vertical compound engine.

In this power unit the high pressure cylinder is 4 in. diameter, the low pressure 7 in., the stroke 61. in., the indicated h.p. being 35. The .whole engine is enclosed in an oil-tight casing, and by the provision of a hand-operated auxiliary valve, it is possible to start with the cranks in any position, steam being admissible to the low-pressure cylinder in case of necessity merely by pressing the knob of a small plunger which onerates the valve in question.

On a square on the crankshaft is mounted the sliding member of the three-speed gear; the three wheels of this mesh with others to correspond on the countershaft, which also carries the front sprocket wheel ; the drive thence is by a long and substantial roller chain to a sprocket on the differential gear carried by the rear axle. This lastnamed component may be described as of normal construction, the material employed, however, being 3i Per cent, nickel steel. The final drive is ingeniously arranged, spiders carried by the driving portions of the s axle having holes drilled into registered driving pins which themselves are driven into and bolted to the road wheels.

The construction, as may be gathered from our illustration, is such that by the withdrawal of a cotter pin from the collar outside the wheel, it is possible to remove either wheel for purposes of tire replacement; it is not necessary, in any case, to remove the axle for this purpose.

The front axle is carried on two half-elliptical longitudinal springs as in motorcar practice, and Ackermann type steering is employed.

The wheels are centrally pivoted, and the steering gear is by screw and nut. The arrangement allows of the maximum ease of steering, and, moreover, it is permissible to operate the steering gear with the wagon stationary. Ball bearings are not used for the wheels, the steering pivots being surrounded by steel rings specially heat-treated, upon which the wheels run on phosphor-bronze bearings.

On the standard wagon, the brake gear is an interconnected foot or screw-down hand type. For urgent application, the driver uses the pedal, and effects rapid brak. mg of the wagon through the

medium of drums bolted to the spiders driving the rear wheels. Slotted links in the connections allow of the hand brake being used independently but acting on the same drum ; it is possible either to put on the foot brake and then, if the wagon has-to stand, hold the brake on by utilizing the hand brake ; or either foot or hand brake may be used as ordinarily constructed. In particularly hilly districts, or wherever so desired, a combined steam and hand brake is fitted instead of the standard arrangement. A small vertical steam ' cylinder operates the lift of the screw upon which the, hand wheel is mounted, thus putting on the brake. • This description applying, in general, to all Yorkshire models, it now remains to point out the special features of the new 3-tonner. They consist of the various alterations and devices necessary to muder 'this wagon as low as possible, and the very considerable difference of 11 in. in the over-all height has been effected as between the old type and the new. This desirable achievement has been attained by alterations of the front axle design, reduction in depth of spring brackets, lessening of the camber of the springs, and reduction of the depth of the brackets carrying the boiler, at the rear end, a similar reduction of spring brackets and of spring camber, as well as the fitting of rear wheels of the same diameter as those on the front, has served the same purpose. Incidentally, it may be pointed out that by fitting the same size wheels all round it is possible, at less outlay, to maintain a sufficient stock of spare tires.

In the course of our inspection, we had a trial run on an empty 3-ton wagon, and after a, run out of same few miles, including climbing of a hill with a maximum gradient of 1 in 91, having then arrived in open country, an attempt was made to show of the wagon's capabilities, and although speed 'is not perhaps essential in the case of a steam wagon, the fact that we were able to do a measured mile in two minutes and five seconds is some indication of the power available ; incidentally, it may be remarked that this was achieved without any undue vibration or straining.